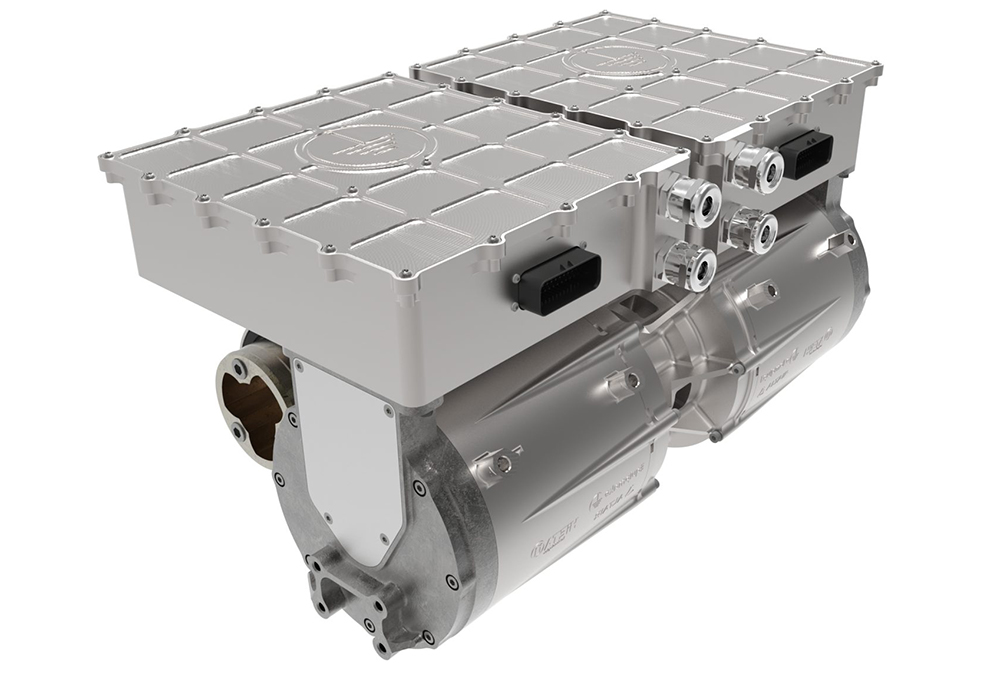

UK electric drivetrain components manufacturer Equipmake has developed a compact, lightweight, high-power electric drive system for manufacturers of high-performance EVs.

Weighing just under 20 kg, the Ampere-220 e-axle system has a peak power of 220 kW, a maximum motor speed of 30,000 rpm and a power density of 11 kW per kg—more than twice that of a conventional electric motor, according to the company.

The key to its performance is its combination of Equipmake’s spoke rotor design with additive manufacturing, allowing Ampere’s metal structure to be 3D-printed, rather than milled from a solid billet.

Debuted with a twin-motor specification, the Ampere-220 e-axle offers 440 kW peak power per axle with a total unit weight of 85 kg. Equipmake can also develop a single-motor e-axle application with 220 kW of peak power per axle.

“We have created the Ampere-220 e-axle by combining it with our own power electronics, including our silicon carbide inverter and transmission system that directly powers the vehicle’s axle,” said Ian Foley, Equipmake’s CEO. “With such an amount of performance in a compact, light unit, one that is also ISO 26262-compliant and ASIL-D-ready, it provides the total off-the-shelf solution for manufacturers of electric sports cars.”

Source: Equipmake