German industrial chemicals firm Brüggemann has expanded its range of performance-enhancing additives for polyamides and polyolefins.

These include flow enhancers, thermostabilizers and impact modifiers as well as an additive that is used to achieve thermoset-like performance, particularly during thermal treatment, while keeping the thermoplastic processing for applications such as polyolefin foams, HFFR compounds and cables.

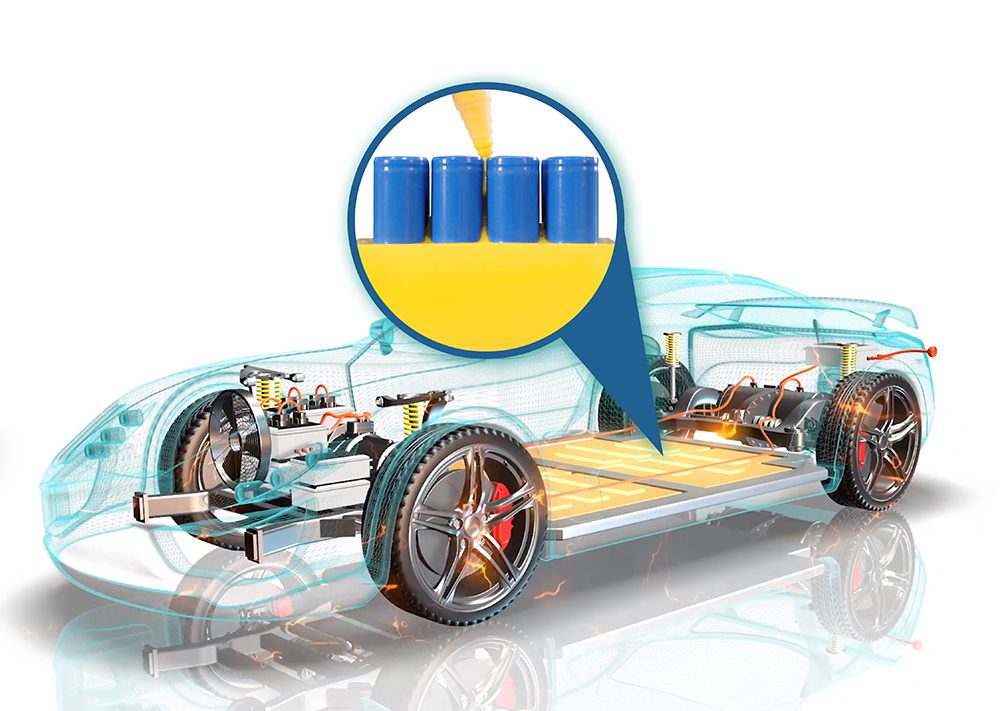

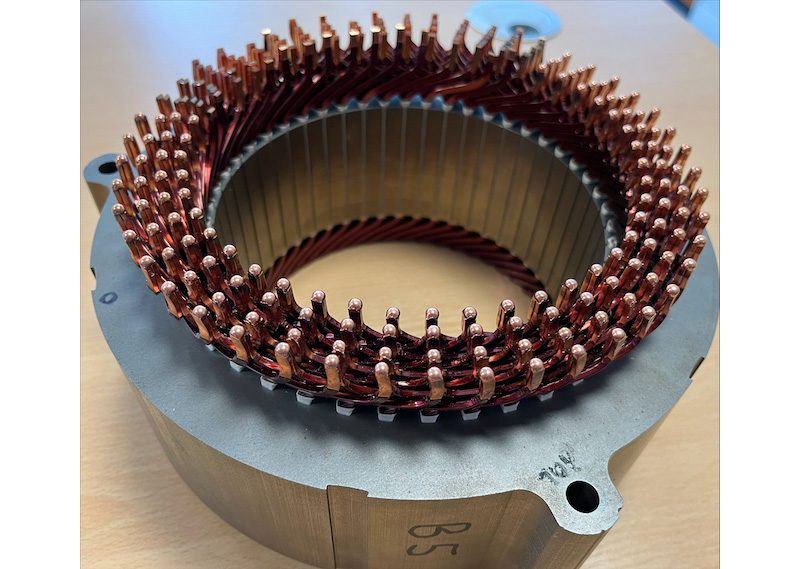

Electric drives pose specific challenges in terms of heat resistance, flame retardancy and the electrical properties of the thermoplastics used, which Brüggemann’s additive portfolio offers customized solutions for OEMs and suppliers to address.

For instance, BRUGGOLEN TP-H2217 is part of a new class of electrically neutral heat stabilizers that the company has developed for the requirements of e-mobility. It raises the continuous service temperature of reinforced polyamides, for example, to up to 8,000 hours at 170° C, without compromising flame retardancy.

Brüggemann has tailored a series of efficient flow enhancers to the requirements of various polyamide types to complement its polymer additives. These include BRUGGOLEN P1507 for aliphatic polyamides, BRUGGOLEN P1810 for semi-aromatic polyamides and BRUGGOLEN P2201 for flame-retardant polyamides.

These flow improvers are designed to enable lightweight, thin-walled and complex part designs without compromising mechanical properties. The flowability supports high glass fiber loadings of up to 60%.

In addition to additives for polyamides, Brüggemann is expanding its portfolio to include stabilizers for cross-linked PE compounds. BRUGGOLEN TP-H2431 is a long-term heat stabilizer for applications in T3 and T4 cables. It is supplied in pellet form, is designed for exceptional thermal stability in continuous use and is suitable for E-beam and Sioplas applications.

BRUGGOLEN R8897 is a new thermostabilizer developed to improve the properties of PP-EPDM recyclates from front-end applications. It is based on a chemical concept that ensures strong retention of mechanical properties during long-term heat ageing.

Compoback is an additive for polyolefin foams, HFFR compounds, cable applications and TPEs, which results in high temperature behaviors that are approaching those of cross-linked plastics, while maintaining the advantages of thermoplastics in terms of reprocessing and recycling, according to the company.

The additive is designed to enable an increase in processing efficiency by eliminating the additional step of radical crosslinking. Its primary effect is demonstrated by the example of extruded, physically foamed PE profiles with a square cross-section. In laboratory tests, their surface area shrank by around 75% after 24 hours of storage at 100° C without stabilization but when compounded with Compoback and stored accordingly, the reduction was negligible, the same as with conventional permanent cross-linking.

Source: Brüggemann