We first told you about Wildcat Discovery Technologies back in the October/November 2012 issue of Charged. It is a venture-backed start-up in Southern California that has developed proprietary methods for rapidly synthesizing energy-storage materials. The company boasts that one of its busy scientists can produce 400 to 500 different battery materials at the same time – that’s in the neighborhood of 100 times faster than standard labs.

Wildcat shares its talents with many material companies and cell manufactures under various collaborative projects, most of which it won’t discuss. Some of the few partnerships that have been made public include a multi-year deal struck in September with the Japanese battery separator giant Asahi Kasei and a new research contract announced in January with the international powerhouse 3M.

When Wildcat is not doing the synthesizing legwork for other companies, it funds internal projects to explore different battery materials that its chemists think they can improve. One of the first internally-funded products it produced was a high-voltage electrolyte additive called EM1, which can be put into conventional electrolyte formulations to give high-voltage performance to the overall cell. The company now reports that there are several major cell makers in late-stage testing to incorporate it into their products.

The latest material science magic that the company has cooked up involves two new cathode materials, dubbed CM3 and CM4.

CM3, announced in March, is a novel, spinel-based oxide cathode with great capacity, low irreversible capacity, good rate performance, good cycle life and (its most important attribute) no voltage fade.

CM4, which Charged got the exclusive first scoop on, is the first known rechargeable copper fluoride cathode – a high-energy, high-power, rechargeable conversion electrode.

CM3 – next generation

One of the top contenders for the next-generation battery technology is a chemistry known as lithium-rich nickel-manganese-cobalt (NMC), originally pioneered by Argonne National Labs. This new cathode material has demonstrated excellent energy density, good power capabilities, and a cycle life that is approaching the requirements of automotive applications.

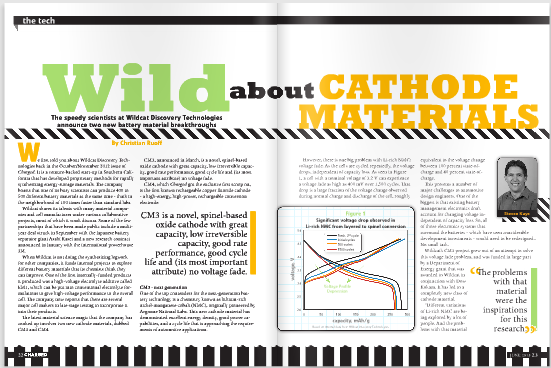

However, there is one big problem with Li-rich NMC: voltage fade. As the cells are cycled repeatedly, the voltage drops, independent of capacity loss. As seen in Figure 1, a cell with a nominal voltage of 3.2 V can experience a voltage fade as high as 400 mV over 1,500 cycles. That drop is a large fraction of the voltage change observed during normal charge and discharge of the cell, roughly equivalent to the voltage change between 100 percent state-of-charge and 40 percent state-of-charge.

This presents a number of major challenges to automotive design engineers. One of the biggest is that existing battery management electronics don’t account for changing voltage independent of capacity loss. So, all of those electronics systems that surround the batteries – which have seen considerable development investments – would need to be redesigned. No small task.

This presents a number of major challenges to automotive design engineers. One of the biggest is that existing battery management electronics don’t account for changing voltage independent of capacity loss. So, all of those electronics systems that surround the batteries – which have seen considerable development investments – would need to be redesigned. No small task.

Wildcat’s CM3 project grew out of an attempt to solve this voltage fade problem, and was funded in large part by a Department of Energy grant that was awarded to Wildcat in conjunction with Dow Kokam. It has led to a completely new class of cathode material.

“Different variations of Li-rich NMC are being explored by a lot of people. And the problems with that material were the inspirations for this research. We didn’t have a way to just fix that material, so we set out to develop a material with similar performance as Li-rich NMC, but without the voltage fade problem,” Steven Kaye, Wildcat’s Chief Scientific Officer, told us.

A number of other researchers had established that, over time, structural changes occur in Li-rich NMC that lead to voltage fade. So, Wildcat decided to start with a variation of the structurally stable material that exists after the voltage fade occurs. After solving a number of technical challenges through many iterations of Wildcat’s super-speedy synthesizing process (creating that material, modifying the structure for sufficient capacity, protecting it from water, etc.), a new material class was born. “We usually refer to it as a lithium-rich spinel,” said Kaye. Basically, it’s on par with Li-rich NMC in terms of performance, but is stable to structural conversion, so it doesn’t experience voltage fade.

A number of other researchers had established that, over time, structural changes occur in Li-rich NMC that lead to voltage fade. So, Wildcat decided to start with a variation of the structurally stable material that exists after the voltage fade occurs. After solving a number of technical challenges through many iterations of Wildcat’s super-speedy synthesizing process (creating that material, modifying the structure for sufficient capacity, protecting it from water, etc.), a new material class was born. “We usually refer to it as a lithium-rich spinel,” said Kaye. Basically, it’s on par with Li-rich NMC in terms of performance, but is stable to structural conversion, so it doesn’t experience voltage fade.

The CM3 material has significantly higher energy density than any cathode material currently on the market – north of 250 mAh/g, an increase of approximately 70 percent in gravimetric energy on a cathode basis.

While the new compound solves the problems of Li-rich NMC, it is not ready to drop into cars. There is development work to be done. The next step is to ensure that the material can be produced using a scalable, low-cost method. “We know it exists – it can be made – so now the trick is turning that into something that is economical on the large scale,” said Jon Jacobs, VP of Business Development at Wildcat. The company is currently looking to partner with material suppliers and/or cell manufacturers, because they’re particularly skilled at scaling up and finding creative ways of producing things using low-cost methods.

How long until we could see CM3, or something equivalent, in new cars?

“Unfortunately, that’s very hard to answer,” said Jacobs. “When you introduce a new cell chemistry to testing, from safety to crash and battery management, it all takes time. It’s in line with what it takes to get other ‘next generation’ materials into cars.”

In general, an automotive design cycle is about five to seven years.

CM4 – next after next generation

If CM3 and Li-rich NMC are considered next generation materials, then Wildcat’s new CM4 could be a contender for two battery generations from now, possibly even three. But that doesn’t make the breakthrough any less significant.

Typically, if you have a battery material that has very low power capacity, but other attractive characteristics, engineers will do what is known as a carbon coating. The process can significantly increase the conductivity of electrodes and protect them from direct contact with the electrolyte, extending cycle life. It is a great technology used with the popular Li-ion phosphate chemistries. But there are a lot of materials that are not stable to the carbon-coating process, such as the carbon fluoride materials Wildcat was researching that became the origin of CM4.

Carbon coating is done at high temperatures in an inert atmosphere and under those conditions copper fluoride is reduced, forming metallic copper. Other materials, such as carbon fluoride and many metal oxides, are similarly reduced.

“We were doing work in primary batteries with carbon fluoride materials,” Kaye explained. “We looked at all sorts of different ways of applying high-power coatings to it. And we found a way of applying a high-conductivity molecular coating at very low temperatures, very mild conditions. It really improved these carbon fluoride cathodes. So, we started saying to ourselves, ‘OK, what else can we do with this? Is there anything else where the big problem is low power but is unstable to carbon coating?’”

“We were doing work in primary batteries with carbon fluoride materials,” Kaye explained. “We looked at all sorts of different ways of applying high-power coatings to it. And we found a way of applying a high-conductivity molecular coating at very low temperatures, very mild conditions. It really improved these carbon fluoride cathodes. So, we started saying to ourselves, ‘OK, what else can we do with this? Is there anything else where the big problem is low power but is unstable to carbon coating?’”

Wildcat began to look at metal fluorides, a class of materials with extremely high energy density, but very low power density because of their insulative properties. Ultimately, it homed in on copper fluoride for a few different reasons – basically, it’s the highest energy metal fluoride that has a reasonable voltage (and is not silver, which is too expensive).

So, the Wildcat scientists took copper fluoride, applied the new molecular technique (that’s like carbon coating, but different), and voila! The result is a high-power and high-capacity electrode.

The theoretical capacity of copper fluoride is about 500 mAh/g – approximately twice that of Wildcat’s CM3 and Li-rich NMCs, and more than three times the capacity of today’s commercially available cathode materials.

“State of the art copper fluoride doesn’t function at all at a 1-C rate. So, if you try to use it at a practical rate, you get nothing out of the chemistry. With our improved special coated copper fluoride, we get over 95 percent capacity at 1-C.”

“State of the art copper fluoride doesn’t function at all at a 1-C rate. So, if you try to use it at a practical rate, you get nothing out of the chemistry. With our improved special coated copper fluoride, we get over 95 percent capacity at 1-C.”

But that’s not the only technological achievement of CM4. In addition to low conductivity and poor power density, traditional copper fluoride also has problems with electrolyte decomposition and dissolution of copper at high voltages (copper oxidizes at approximately 3.5 V, but copper fluoride recharges at 3.55 V). By developing new compositions, coatings, and electrolytes, Wildcat mitigated these problems and managed to get copper fluoride to cycle. Recharging this chemistry is a feat that has not been reported in any other literature or patents, in which copper fluoride variations are always referred to as primary batteries – as in non-rechargeable, designed to be used once and then discarded.

Presumably, since the cycling of copper fluoride has only begun to be explored, there is still a lot of creative engineering needed to get anywhere near the automotive requirements of 3,000-plus cycles. If CM4 can live up to its potential, we’ll likely see it used in mobile electronics applications first – where the useful benchmark is between 300 and 500 cycles.

The company is not ready to fully disclose the cycling results of their CM4 project, but told Charged that it expects to have some impressive stats available in the fall of this year, when the search for CM4 development partners will begin.

As with its other internally-funded discoveries, Wildcat hopes to team up with the industry’s commercial material makers so that it can stick to what it does best: synthesize, test, repeat (in a massively parallel way).

This article originally appeared in Charged Issue 8 – JUN 2013