In the eyes of an EV driver, the success of the battery is measured in a completely binary way: does the battery last the life of the vehicle, or not? In fact, the best praise you can give any battery – whether in your laptop, phone, or EV – is not to have to think about it at all.

While the chemistry and material science of batteries continue to improve, there are still external factors that affect battery performance. For example, at low temperatures, a battery’s available capacity decreases significantly. For cold climates, this fact is a huge challenge for EV designers.

“Batteries suffer from the Goldilocks syndrome,” explains Mike Kelly, founder and President of Calienté. “They don’t like it too hot or too cold. They like it just right.”

Calienté is an Indiana-based designer and manufacturer of thermal systems for a variety of markets, from the telecom industry to military equipment to their latest venture, EVs. Calienté has designed and developed several solutions to circumvent the problem of batteries getting too cold, a problem which, according to Kelly, has been largely neglected.

“It’s one of those things where cooling is the 800-pound gorilla in the thermal world, and then heating is an afterthought that you get to later,” he says.

How to heat a battery

Battery cooling has been a technology of interest in the EV market for some time, so cooling technology has had more of a chance to mature than heating. However, several methods of battery heating have been developed, some making use of existing thermal solutions.

“We saw there were three main ways to cool battery packs,” Kelly explains of Calienté’s foray into EV battery heating. “Once batteries have a cold plate and fins and a coolant system in place, it’s way easier to use that to heat than to reinvent the wheel and try to do something else. So we said, let’s find a way to tap into that cooling architecture.”

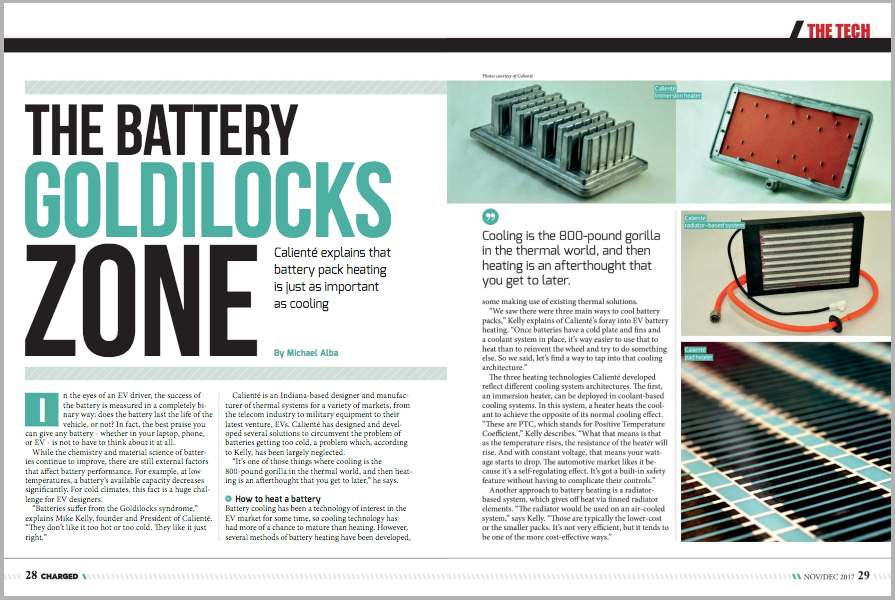

The three heating technologies Calienté developed reflect different cooling system architectures. The first, an immersion heater, can be deployed in coolant-based cooling systems. In this system, a heater heats the coolant to achieve the opposite of its normal cooling effect. “These are PTC, which stands for Positive Temperature Coefficient,” Kelly describes. “What that means is that as the temperature rises, the resistance of the heater will rise. And with constant voltage, that means your wattage starts to drop. The automotive market likes it because it’s a self-regulating effect. It’s got a built-in safety feature without having to complicate their controls.”

Another approach to battery heating is a radiator-based system, which gives off heat via finned radiator elements. “The radiator would be used on an air-cooled system,” says Kelly. “Those are typically the lower-cost or the smaller packs. It’s not very efficient, but it tends to be one of the more cost-effective ways.”

However, the third heating system is the one Calienté is most excited about. Referred to as a pad heater, this technology is used in cooling systems that have a cold plate built in. By embedding a thin heating pad into this cold plate, Calienté can bypass the coolant and heat cells directly.

“The pad is right within the cold plate,” explains Kelly. “In these types of cooling systems, they bond the battery pack modules onto a cold plate to cool it. Picture a large plate with fins going up between the stacks in the modules that pull heat out of the system. We can drive heat from that plate back up through those fins into the system.”

Pad heating

While Kelly is careful not to try to predict the future, he’s very optimistic about the pad-style approach for battery heating. “We always say we’ll go where the market goes, and we’ve got all three technologies,” he emphasizes. “But the pad heater seems to be the best potential fit. And that’s direct feedback from one of the larger pack companies.”

Because of its novel approach in making use of the cold plate, Calienté’s pad heater offers a number of advantages over other heating solutions. “What we thought is, let’s actually embed a heater pad within the cold plate,” Kelly says. “So instead of having an isolated element somewhere far away from the pack, and fluid lines that lose energy as you move the fluid through the line, we put it right at the source. That way we can spread the heat out much more evenly and bring the pack up to temperature in a much more uniform manner. And OEMs don’t have to worry about a certain cell getting hotter than the others, because we can vary the watt density and all that.”

Furthermore, because of the small size of the heating pad, this approach doesn’t demand any trade-off to the existing cooling system. “These parts are only about eleven thousandths of an inch thick. We can put that in the cold plate and not impact the cooling performance,” says Kelly.

In spite of the early promise of pad-style heating, it wasn’t until Calienté engaged the market that the team realized exactly what they had on their hands. “At first we thought it would just be for refrigerant-based systems, because refrigerant is not very thermally conductive,” recalls Kelly. “It’s difficult to move heat through refrigerant, so we thought this is kind of the perfect solution for that. But what we found in engaging the market is that it’s much more efficient for even coolant-based systems to use something like the pad approach. It’s because you’re heating much more directly, you’ve got the PTC effect in place, it’s lower weight, and it’s lower cost than an immersion heater will typically be.”

The road to the Goldilocks zone

Although OEMs have largely focused on battery cooling in the past, Kelly suggests that the EV market seems to be ready to finally embrace battery heating. “Like I said, it’s been one of these things where they took care of the cooling problem first. But I think the market is finally realizing that they’re going to need [heating] if they’re going to sell EVs in places beyond California. So we’re seeing it in more and more applications.”

As for Calienté, its technology is being explored by a number of OEMs and battery pack manufacturers, and is even on the road in some markets. “We have some elements in EV buses overseas,” says Kelly. “And we’re in pre-production validation build on a big project that will be launched in Europe late 2019, and on a couple of cost-reduction projects for current vehicles.”

If EVs are to continue gaining popularity in climates other than the sunny paradise of Silicon Valley, battery heating systems will become just as necessary as their cooling counterparts. And if Calienté’s pad heaters are as effective as Kelly claims, they’re sure to be a competitive player in this emerging thermal domain.

“It’s very rare in the heating world that you’re able to bring this much innovation that ticks this many boxes in a theory that’s relatively in its infancy,” says Kelly. “Hence the excitement on our end. We kind of caught lightning in a bottle, so to speak.”

This article originally appeared in Charged Issue 34 – November/December 2017 – Subscribe now.