The business case for electrifying commercial vans would seem to be a no-brainer – the savings on fuel and maintenance are substantial and demonstrable. In the real world however, pilot projects are plentiful, but substantial orders have been slow to materialize. More than one promising startup has gone under while waiting for fleet customers to take the plunge.

Meanwhile, Michigan-based New Eagle has quietly thrived, making control software and systems for a variety of applications, including traditional ICE powertrains and hydraulic equipment. It has been involved with EVs and hybrid vehicles for over 10 years, supplying control systems and other components to vehicle manufacturers.

With battery costs trending ever lower and public awareness of EVs edging higher, the fleet market seems likely to start plugging in in a big way soon. New Eagle is well positioned to take advantage of the coming wave of electrification.

Charged recently sat down with New Eagle’s Director of Key Accounts and Vendor Relationships Dwayne McKenzie and Engineer Justin Goeglein to talk about the company’s EV control software and its modular Powertrain Kit.

New Eagle was originally founded as a software company. It was purchased by Mercury Marine, a division of Brunswick, which used New Eagle’s motor controls for gas engines. Brunswick eventually rolled New Eagle’s software into its MotoTron line of electronic controls, which was later sold to Woodward, a key supplier to New Eagle.

In 2006, founder Richard Swortzel decided to start up New Eagle again, and the company has been steadily growing ever since. When the EV market began to emerge, New Eagle became a supplier to some of the early players, helping them build control systems for their vehicles.

“Our primary core is control system solutions using model-based development software and production hardware,” Justin Goeglein told Charged. “Our software tool makes it really easy to write software, and we leverage production hardware that’s already been validated. That’s our business model. We’ve been focused on EVs because those solutions work well as different companies are entering this technology.”

Software, supervisors and solutions

“The core of what we offer is a supervisor software package that we’ve built up as a template over years of different projects,” says Justin. “This is the software that controls the torque path and manages the various components on the vehicle. With EVs, we enable customers to safely control motors, while considering the battery and inverter limits.”

However, New Eagle is more than just a seller of software. The company works closely with customers to help them develop control systems tailored to their specific requirements. “We like to teach people how to use our software and tools and send them on their way,” says Justin. “We can only do so many projects a year, but if we teach them how to use our tools appropriately then they can go out and do more projects and help us to spread the offerings we have.”

“Many times we have customers that have already invested in the MATLAB and Simulink software suite. New Eagle brings the software platform that links that up to hardware components that they can build a control system off of, so they don’t have to develop their own from scratch. It costs about one tenth of what it would cost to use other products.”

New Eagle also acts as something of a matchmaker, helping small and medium-size companies get hooked up with component suppliers. “New Eagle has relationships with most of the major OEM players in the EV market – BorgWarner, UQM, Parker, YASA, SEVCON, Rinehart Motion Systems, Engineered Machine Products, Mitsubishi, Climate Control Systems, EDN Group, Current Ways, and many others,” says Dwayne. “That’s one of the unique capabilities you get when you work with New Eagle. We’re a central place where you can get access to all of these vendors easily.”

“The major component OEMs may not have the bandwidth to support a company that’s going to place sub-1,000-unit orders, but they have experience working with New Eagle. So we help companies get through some of the engineering challenges.”

Electrifying the Transit

New Eagle made an impression at the recent Detroit auto show with an electric Ford Transit that it developed with partner Inventev. The two companies plan to begin production of the vehicle in early 2018. New Eagle will provide the core propulsion systems and controls, and Inventev will handle upfitting and distribution.

“We’re great at system integration, so we decided to leverage that by partnering with a production house in order to supply a truly marketable system to fleets,” says Dwayne. “Inventev has the capabilities and the background to actually productionize things and get them out there to the market. We combined our technology and their ability to manufacture, and that’s where we think the big win is going to be.”

“The objective is to have Inventev go out and sell to upfitters and/or become an upfitter itself,” Dwayne continues. “Ford has very specific programs that they set up with upfitters, which is another reason we chose the Transit. New Eagle and Inventev will join that program.”

“We like the Transit because it’s an American-made, rear-wheel-drive platform that expands across a pretty broad payload,” adds Justin. “It really worked well because of the rear-wheel drive and the size of the vehicle, and we’re continuing to expand our relationship with Ford – they’ve been really supportive.”

One kit fits all

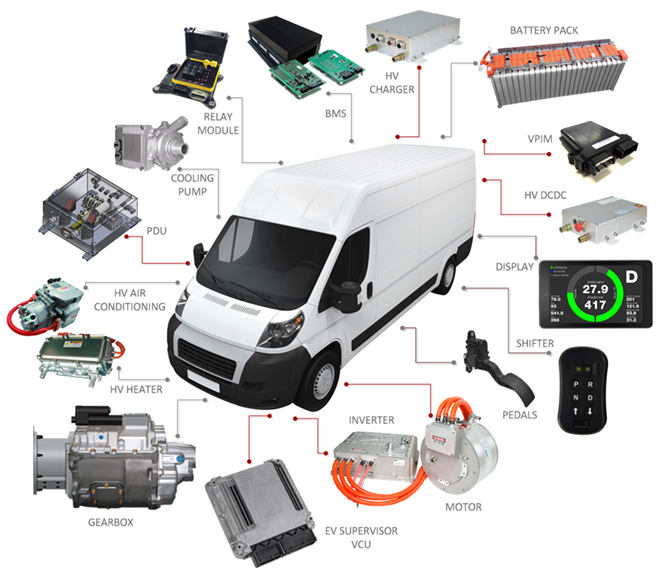

The electric Transit was developed using New Eagle’s customizable Powertrain Kit, which is designed to allow fleets and manufacturers to quickly and affordably convert light- and medium-duty commercial vehicles to electric drive.

“As we’ve gained experience in the EV market, we’ve been able to develop a kit where we’ve pulled together a complete powertrain,” says Justin. “It leverages our vendor relationships and our experience with those different products so that we can offer a package that has everything needed to convert a vehicle from ICE to electric powertrain.”

“The Powertrain Kit is a complete replacement package. It includes the brains or vehicle controller (which is our focus), an inverter, motor, DC/DC converter, charger, electro-hydraulic power steering pump, and vacuum pump. Climate control is achieved through a high-voltage heater and a high-voltage AC compressor, all of which interfaces with the Ford OEM system.”

“The beauty of what we put together is that we could swap out any of the components in the kit depending on the needs of the customer,” said Dwayne. “The control system can easily adapt. So we can design a system based on different duty cycles and use cases.”

“We have a detailed powertrain design where we have all the low-voltage and high-voltage electrical schematics, and we’ve made it very modular,” says Justin. “And we own this validated software set that works with all these different components.”

“That’s why we can have a very similar powertrain kit that stretches from a small to mid-size vehicle all the way to the heavy-duty. In the same powertrain package that’s in the Transit, those components can handle light-duty or medium-duty vehicles, depending on the duty cycle, and they can pretty easily be adapted for different applications.”

To give one example, different customers might require different charging times, and New Eagle can easily meet their needs. “We have relationships with different charging vendors, including BRUSA, EDN, and Current Ways, and they all have different power levels available,” says Justin. “So we can offer different charging times from roughly 8 hours down to one hour, depending on the size of the pack and which charger you select.”

The same applies to the battery pack – whatever range a customer needs, New Eagle can choose the perfect pack from a variety of vendors. More range is usually a good thing, but right-sizing a battery pack, so that a vehicle has just enough range for its intended use case, can help maximize cargo space and keep costs down.

“As far as maximum range, there is a pretty big cargo area in that van, so we could put a lot of batteries in it,” Justin explains. “Some of those guys are putting 150 miles per day on their vehicles, but I think most of our highest-interest customers have a need for a range well below that. The commercial market has a little bit less range anxiety, because it’s really driven by data, and fleet managers really understand the use cases of those vehicles.”

New Eagle sometimes buys complete battery packs from vendors, and sometimes assembles a custom pack from modules. “We try to maintain high flexibility with the batteries, because different customers have different ideas on how they want to do it,” says Justin. “We’ve worked with some of the big battery suppliers that give you a complete pack, and we interface with their battery management system (BMS). They handle the packaging and cooling as one big pack. We’ve also done it at the module level – we offer a CAN interface in case you want to meet a generic standard that we’ve defined to work with our supervision software. In case a customer wants to build their own battery pack, we have a BMS that we can help them configure to make sure that we’re monitoring the correct things and that it works with our supervisor.”

Control freak

New Eagle’s EV Supervisor Control Module is the heart of the Powertrain Kit, providing several critical functions. “It starts with torque security,” Justin explains. “That includes a dual-band pedal with arbitration so you can make sure you’re properly reading the driver’s request, and that includes torque security feedback from the motor. And most importantly, it takes into account the limits of the battery pack, so you don’t overuse the available power from the pack and you stay within its limits, as well as the limits of the inverter.”

“We also handle the proper startup and shutdown of the high-voltage system, which includes making sure the components wake up in the right order, the high-voltage system is pre-charged properly, and you only transition into drive mode with the proper interlocks.”

“We have interfaces for component control, which is necessary to make sure you’re operating the different components at their correct operating points, including HVAC and other accessories. We also offer charging controls so we make sure we charge the pack with the available power from the grid, taking into account what the charger can do and what the pack can handle.”

Is the fleet market ready?

Fleet electrification has seemed to be just around the corner for several years now, and several companies that focused exclusively on converting fleets to EVs have crashed and burned. New Eagle, which has always served a broader range of markets, has been able to steadily build relationships with suppliers and constantly improve its software package, while learning from others’ failures.

Dwayne and Justin are convinced that the market is ready to take off soon: “It makes sense in terms of a payback period, and there are a lot of other advantages.”

Understandably, many are skeptical. In 2010, a company called Azure Dynamics set out to offer an electric version of the Transit, and it didn’t end well.

“I saw one internet comment on an article about our Transit project that said, ‘Yeah, we’ve seen this before. Can anyone say Azure Dynamics and bankruptcy?’” Dwayne relates. “And I thought that was funny, because it’s not wrong – unfortunately there have been many people that failed at similar projects in the past. But the technology wasn’t there – the pricing of the components has really come down. That was a long time ago relative to where this industry is now.”

“We’ve been around for a while, and have helped many startup companies in the past that have had challenges communicating with the end users on the value of the technology – they’ve had trouble with components not being ready and financing not being ready,” says Justin. “Today it’s a different story – the market really seems to be much more ready to adopt this technology. People are starting to understand it. We don’t have to explain things as much.”

The components have also gotten better. “Today we’re able to leverage products that have been out in the market for years,” says Dwayne. “For example, UQM motors and BorgWarner/Remy motors have been around for a long time, and it’s now proven technology. Companies like Azure and Bright Automotive were breaking totally new ground trying to bring something to market, and having to spend millions of dollars to do it. We don’t have to do that. Other people have already validated these motors, inverters, and everything else.”

This article originally appeared in Charged Issue 30 – March/April 2017 – Subscribe now.