This article is an excerpt from Tesla Motors: How Elon Musk and Company Made Electric Cars Cool, and Sparked the Next Tech Revolution by Charged Senior Editor Charles Morris. This 270-page book is a comprehensive history of Tesla, told by the entrepreneurs who made it happen, as well as an assessment of the company’s lasting influence on the automotive industry and beyond.

When the Tesla team built the historic Roadster, they started with an electric powertrain from AC Propulsion, and adapted many other parts from the Lotus Elise. As Marc Tarpenning told me, the company’s business plan depended on the fact that it would not have to spend millions developing all the components of a vehicle from scratch. In the end (of course), the process of turning an ICE vehicle into an EV proved a little more complicated than the Teslanauts had imagined.

Years later, when it was time to design the Model S sedan, Tesla took a very different approach. To build a vehicle “from the ground up” as an EV is an engineer’s dream – a dream that the Tesla team was able to realize for the first time in automotive history.

In a 2012 interview, Elon Musk mused that the strategy of adapting an existing vehicle hadn’t worked out so well for the Roadster. “As it turned out, the AC Propulsion technology didn’t work, so we had to redo all that. And the Elise – once you added the electric powertrain, it invalidated all the crash work, the mass grew by 30 percent, the weight distribution was different, the load points were all different. We had to stretch the chassis just to be able to fit people in, so that turned out to be a really dumb strategy, too. So it was like you wanted to build a house, couldn’t find the right house, so you try to fix an existing house and end up changing everything except for one wall in the basement. It would have cost way less to just level the house and start from scratch. What sounded like a good idea at first, which was to leverage the Elise chassis, was actually an incredibly dumb idea.”

Dumb or smart, that’s the way EV-builders had always done things. In fact, when an automaker designs any new model, it makes every effort to reuse and recycle existing parts and technology, and avoid “reinventing the wheel.”

Automakers began using interchangeable platforms in the 1960s. Originally, the term referred to the physical chassis of a vehicle. Today, it’s a more inclusive concept that may include not only physical components such as the floor pan, axles, suspension, steering and powertrain, but also design, engineering, and production processes.

The Volt is built on GM’s Delta II platform, which it shares with its gas-powered cousin the Cruze. The LEAF theoretically has its own platform, but its direct antecedent, the EV-11 prototype, was based on the Versa. Most other automakers have not only used an existing platform for their EVs, but have taken an existing model and simply swapped out the powertrain. The Honda Fit EV, Mitsubishi i-MiEV, Ford Focus Electric, Toyota RAV4 EV and smart electric drive are more or less gas models retrofitted with electric powertrains.

On the face of it, this strategy makes a lot of sense. After all, other than the engine, transmission and gas tank, most of the other bits of an automobile – body, interior, lights, electronics, wheels, suspension – can be exactly the same, regardless of the powertrain.

However, this approach requires the designer to make a series of compromises that trade away many of the benefits that an electric powertrain can offer. In other words, an EV can only really shine when it has a chance to do so on its own terms. EVs have many advantages over ICE vehicles, but for a designer to maximize those advantages, he or she needs to throw out the chassis and body that evolved to meet the needs of gasoline engines, and start over with a brand-new design.

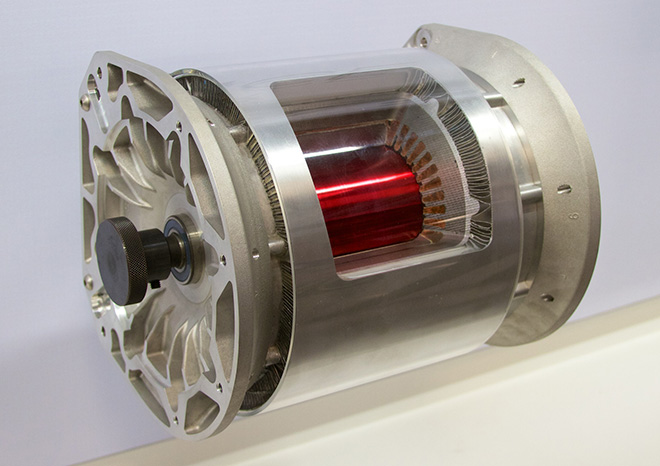

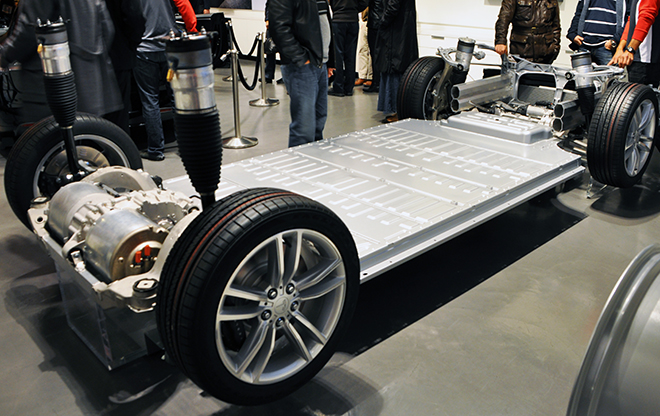

The most important design differences have to do with space. An electric motor is much smaller than a gas engine of similar power, and it can be placed right between the driven wheels (a few companies, such as Protean Electric, profiled in our June 2013 issue, have even designed motors that fit inside the wheel hubs). An EV needs no transmission as such, so there’s no need for the central tunnel that takes up so much space in rear-wheel-drive gas vehicles. There’s also no need for an exhaust system, thermal shielding or a catalytic converter. The body of a gas vehicle has been designed with spaces for all that stuff, so if you convert it to an EV, much of that space is likely to be wasted.

On the other hand, there is one component of an EV that is necessarily large and heavy – the battery pack. If you’re working with an existing gas-engine-based design, there’s simply no good place for it to go. Many designers have opted to put it in the rear of the vehicle, and cannibalize much of the trunk space, which is why most EVs have much less cargo space than their gas counterparts.

If you start with a “clean sheet of paper,” you’re bound to come to the conclusion that the best place for the battery pack is the bottom. This yields several advantages. It gives the car a low center of gravity, which greatly improves handling. It allows the car to be designed in such a way that the battery can be easily removed, to be serviced or swapped out for another. Most significantly, it means that the entire interior space of the car, from front to back, can be devoted to passenger and cargo space.

“The architecture of Model S is really similar to a skateboard,” Tesla design chief Franz von Holzhausen told Bloomberg. “The floor of the vehicle is the battery pack, and the motor is between the rear wheels. Everything above that is the opportunity space.”

This concept is nothing less than a revolution in automotive design. Thanks to its bottom-dwelling battery, the Model S has excellent handling, and it has far more interior space than other sedans of its size: room for up to seven passengers (with the optional jump seats), a rear cargo area that’s more like that of a hatchback than the trunk of a sedan, and a “frunk” where the engine isn’t. It’s also theoretically safer than a dinosaur-burner, at least in a frontal collision, because the frunk provides a long crumple zone in the front, instead of a heavy hunk of hot metal to be rammed into the passenger compartment.

A bottom-mounted battery pack does have one drawback, which was highlighted in 2013, when two Model S caught fire after colliding with road debris that punctured their battery packs (of course, most gas tanks are also located in a car’s vulnerable underbelly). Tesla addressed the issue by strengthening the bottom plate and slightly increasing the car’s ground clearance. As more and more Teslas hit the highways, it’s possible that this issue may resurface someday, but the advantages of the battery-on-the-bottom design are so great that EV designers will probably continue to choose it (as BMW did for its i3).

There are many more advantages to be gained by designing an EV as an EV. Efficiency is important for any auto, at least if you care about saving gas, but for an EV, it’s absolutely critical, because every bit of wasted energy means a shorter range. The aerodynamics of the body, the rolling resistance of the tires, the energy consumption of the lights and the air conditioner – all these things and many more all add up to affect how far you can drive on a charge. Only designing a car from scratch lets you squeeze every extra electron out of all these interacting parts. For the same reason, weight is critical. Starting with a tabula rasa lets you choose the lightest parts available, from the aluminum or carbon fiber body panels to the aluminum screws (hopefully without sacrificing durability or safety).

Charles Morris goes on to tell the story of how the Roadster took the automotive press by storm (a little too stormy in the case of the British TV show Top Gear, with which Tesla got into a lengthy round of recriminations and lawsuits). But a rocky road lay ahead. A tide of red ink threatened to swamp the company before it could get the Roadster to market, and personality clashes in the boardroom caused the original management team to break apart. For more information on Charles’s new book, see www.teslamotorsbook.com.

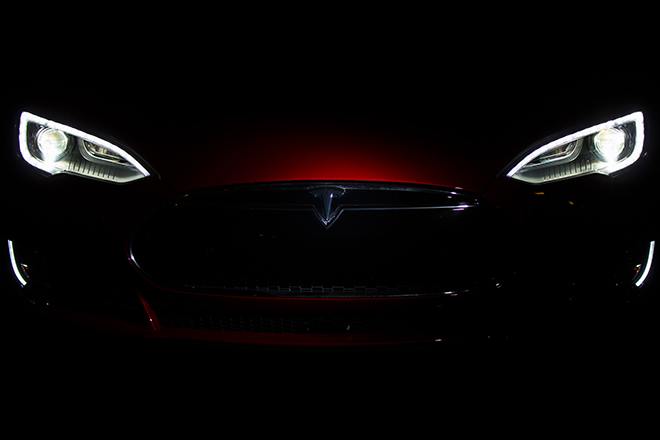

Top Image Courtesy of David P. Discher/Flickr