The methods that automakers use to join Li-ion cells together are almost as diverse as the sizes and shapes of the cells themselves. EV builders are using spot welding, mechanical fasteners, wire bonding and other joining techniques. It’s safe to say that there is no consensus on an ideal solution, and that there’s a lot of room for innovation in the field of battery pack packaging.

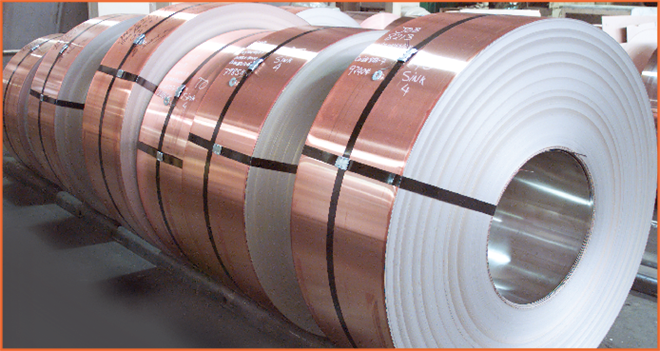

Engineered Materials Solutions (EMS) believes its clad metal technology is one of those innovations. The company recently told Charged that automakers are looking closely at using more clad metals in Li-ion battery packs to provide joining solutions, lower costs, increase conductivity and improve thermal management.

Clad metals

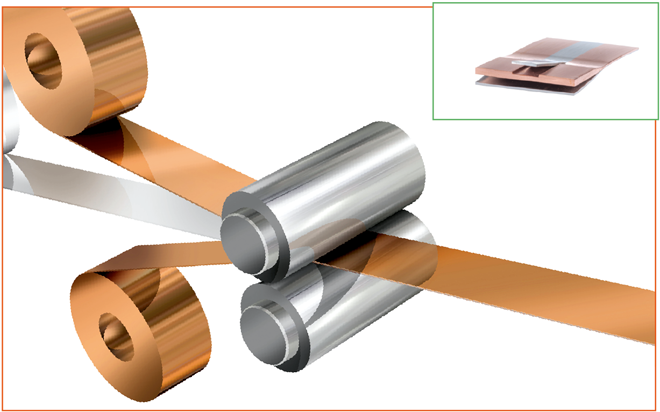

Cladding is a process of bonding together dissimilar metals, and it is commonly achieved by extruding multiple metals through a die, or by pressing and rolling sheets and coils together under high pressure. The technique has been used by metalworkers for over a century. Perhaps the most commonly known clad metal application is coin currency. The US Mint, for example, uses clad metals to produce coins such as the US quarter and dime.

EMS was originally founded in 1916 when it began creating specialty clad metals for the jewelry industry. At that time, the company’s products included materials that had a surface of precious metal for the desired appearance and cosmetic characteristics, but incorporated additional metals that would enhance mechanical properties and reduce cost.

Today, clad metal materials are widely used in household appliances and circuit breakers in the form of thermostatic bimetals, and one of EMS’s two divisions is specifically dedicated to this technology. Thermostatic bimetals use two or three different types of metals layered together. The materials are designed in such a way that they will change shape when heated to a certain temperature. This occurs because each metal has a different coefficient of thermal expansion, so they expand at different rates when heated, causing them to bend. That shape change is then used to open up a circuit and cut off power in a circuit breaker or an appliance like a toaster or a dishwasher.

The other half of EMS’s business – specialty clad materials – includes highly engineered products for applications like truck bumpers, heat exchangers, button cell batteries, cookware, shielding for buried telephone cables, catalyst foils for exhaust applications…and the list goes on. “There are so many applications where using a single mono-metal is not ideal,” said EMS Vice President Jim Glennon.

EMS also produces two products that it says are ideally suited to improve connections in the advanced battery packs found in EVs. The company’s SIGMAclad and Corelok product lines were developed specifically for Li-ion battery packs using cylindrical, prismatic or pouch cells.

Cylindrical cells

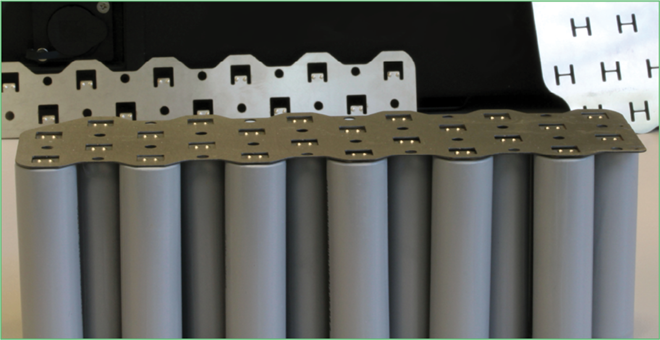

One of the most common methods for joining cylindrical cells into a pack is to use strips of pure nickel that are spot-welded to the cell’s terminals. However, as the power requirements and number of cells in a pack increase, so does the heat generation. So, engineers are constantly looking for more advanced solutions to mitigate the higher temperatures, which can reduce efficiency and increase battery degradation and the risk of fire.

EMS says it can improve both cost and performance by replacing pure nickel or alloys with SIGMAclad – a five-layer sandwich of copper, stainless steel and nickel.

The main benefits of nickel are that it has a natural corrosion resistance and that it is easily spot-welded or soldered, while offering high-strength welds. After nickel tabs are spot-welded to the cells, many pack designs also include a BMS with leads that are soldered to different points of the nickel bus.

“However, the problem with nickel is that it has very high resistivity and poor conductivity,” said Michael Hardy, Business Development Manager at EMS. “Heat is a function of the material’s resistivity, so high loads generate a lot of heat.”

The first logical step to try to use cladding to improve the material properties is to sandwich a layer of copper between layers of nickel. However, EMS found that the result was too conductive. “If you use a clad nickel-copper-nickel bus, it’s going to be a very poor alloy to resistance-weld,” explained Hardy. “The copper dominates the conductivity so well that it removes the local heat too quickly when you’re trying to spot-weld the material to the battery.”

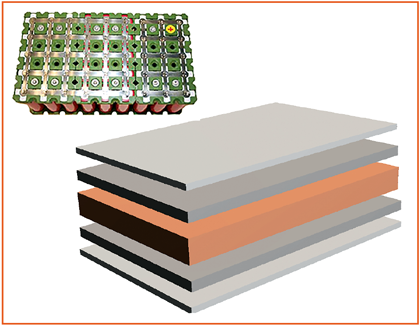

So, EMS then developed a five-layer product with copper in the center surrounded by stainless steel and then a nickel exterior. “The stainless steel layer keeps the heat localized long enough for resistance welding and it also adds strength,” said Hardy. “The result is our SIGMAclad material, which reduces the resistivity in the bus by 50% or greater, and can be easily welded.”

SIGMAclad is available in three ratios corresponding to 30%, 40% and 60% IACS (a unit of electrical conductivity for metals and alloys relative to a standard annealed copper conductor) depending on electrical and thermal requirements.

EMS says that because the SIGMAclad material has a symmetrical design, the expansion effects counteract each other. “The five layers give it a symmetrical configuration on both sides of the copper,” explained Hardy. “So when it’s thermally stressed, one side of the copper wants to act in one direction and the other side wants to act in the other direction, and they cancel each other out. When it cycles, it sees a balanced system that will not stress the weld joints.”

The company said some of its customers are currently conducting long-term durability tests with SIGMAclad, evaluating joint stress and weld performance, and they’re well into the program “without any failures.”

Prismatic and pouch cells

The fundamental joining challenge with pouch and prismatic Li-ion cells is that the connecting tabs for the anode and cathode are dissimilar metals – aluminum and copper. Historically, these two metals are not typically weldable in a reliable and repeatable way.

If the cells are joined in parallel, there is no issue, but in vehicle applications they are often joined in series, and packs can have hundreds of copper-aluminum connections. So manufacturers need to be able to spot-weld them in a very controllable and predictable way. “We’ve seen people trying everything they can to weld copper and aluminum, but the result is a brittle joint that’s very prone to fracture,” said Glennon.

To address these challenges, EMS developed Corelok. It’s an edge-bonded copper-aluminum product that allows pack manufacturers to weld similar metals during assembly. The company uses multiple metal strips to create a clad finger joint. “We’re cladding the metal in a multi-stack configuration by feeding a number of layers into the mill,” said Hardy. “This increases the surface area for the bond zone between the copper and aluminum.”

EMS says the requirements of the automotive industry are well within the capabilities of clad metals. At extreme temperatures the atomic-level bonds of the metals could weaken. However, the maximum temperature found on a vehicle is about 300° F. The company says that its products will not delaminate anywhere near that temperature. “Vehicles are way below what we would consider to be risky temperatures for these materials,” said Hardy.

Cutting costs

No matter how well a new technology performs, the auto industry is extremely sensitive to its cost structure. EMS believes that its battery joining solutions will pencil out to a win for EVs.

In fact, the company says using SIGMAclad for joining cylindrical cells will not carry a cost premium over pure nickel. “It’s actually very competitive,” said Hardy. “And for the industries that have significant thermal management issues, the alternative mitigation techniques tend to be much more expensive than SIGMAclad. Some alternatives we compete against include using an aluminum heat sink or spot-welding copper to nickel, and both carry a cost premium.”

In terms of using Corelok to join prismatic and pouch cells, EMS says that there really isn’t a good monometal solution to compare costs to. “Some people claim to be able to weld copper to aluminum, but we haven’t seen a reliability that is up to the standards of the auto industry,” said Hardy. “You may get 1,000 good welds, but if the 1,001st is poor, that can be problematic in a vehicle.”

Edging into automotive

EMS’s ambitions for expanding in the growing EV industry don’t stop at its battery joining solutions. It is currently working on clad metal products for power electronics cooling, and also battery applications that are internal to the cell. The company told us that it is in the testing and development phase with materials that will be part of the cell’s chemistry.

For the more established SIGMAclad and Corelok technologies, EMS has “a couple of programs going on right now, like an electric delivery truck design with cylindrical cells,” said Hardy. “And a number of programs with different OEMs for the pouch and prismatic type applications that are 2017-2020 timeframe designs.”

This article originally appeared in Charged Issue 27 – September/October 2016. – Subscribe now.