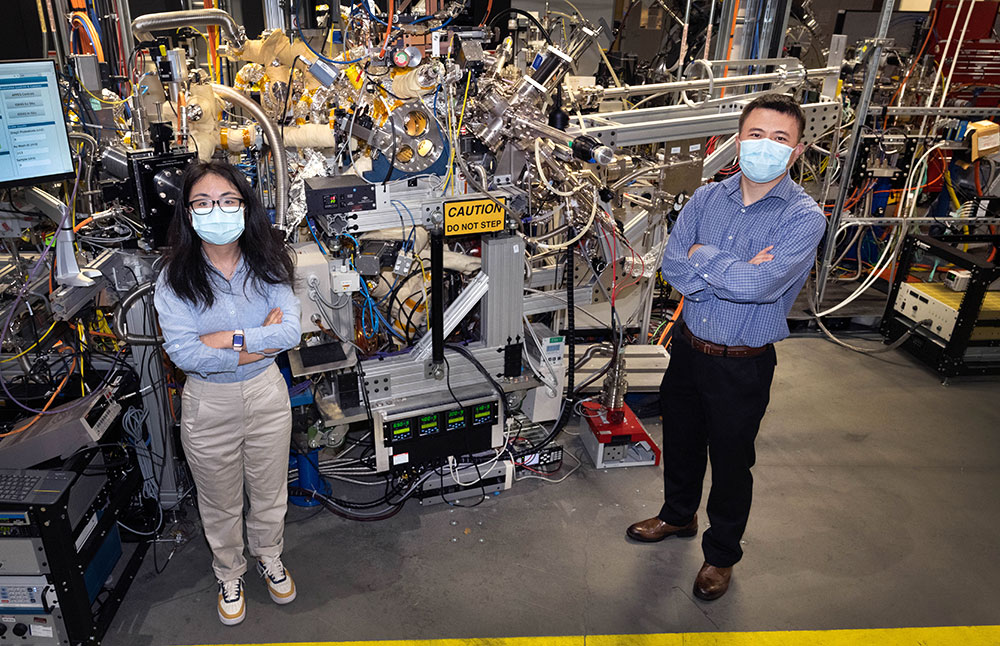

A team led by researchers at DOE’s Brookhaven National Laboratory has investigated the benefits of a lithium difluorophosphate additive for electrolytes in lithium batteries with nickel-rich layered cathodes.

According to Brookhaven, the possibility of high-energy-density cells composed of nickel-rich layered cathodes and lithium metal anodes is limited by processes that reduce their capacity.

In an article published in Nature Energy, the researchers write: “The [additive’s] decomposition products (Li3PO4 and LiF) form a protective interphase. This suppresses transition metal dissolution and cathode surface reconstruction. It also facilitates uniform Li distribution within the cathode, effectively mitigating the strain and crack formation.”

“By forming a very stable interphase on the cathode, this protective layer significantly suppresses the transition metal loss on the cathode surface,” said study co-author and Brookhaven chemist Enyuan Hu. “Reduced transition metal loss helps to decrease the deposition of those transition metals on the anode. In that sense, the anode is protected to a certain extent as well. We believe suppression of transition metal dissolution is one of the key contributors that lead to significantly improved cycling performance.”

The researchers also found that batteries with the additive retain 97% of their capacity after 200 cycles.

Brookhaven says cathodes with a polycrystalline structure are thought to cause particle cracks and capacity fade. “Our work is saying that polycrystalline materials cannot be excluded from consideration, especially because they are easier to make, which can be translated into a lower cost,” said Hu.

“Our strategy uses a very small amount of additive to achieve such great improvement of the electrochemical performance,” said study co-author Sha Tan. “Practically speaking, this could be a low-cost and easy-to-adopt solution.”

The next priority for the researchers is to test the additive through higher cycle counts.