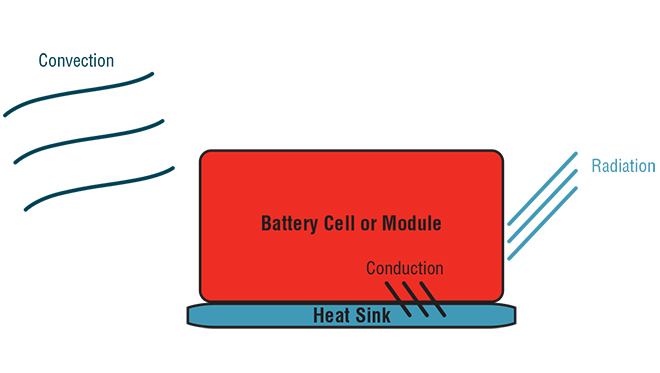

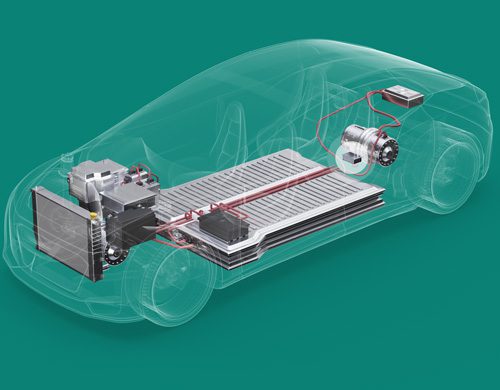

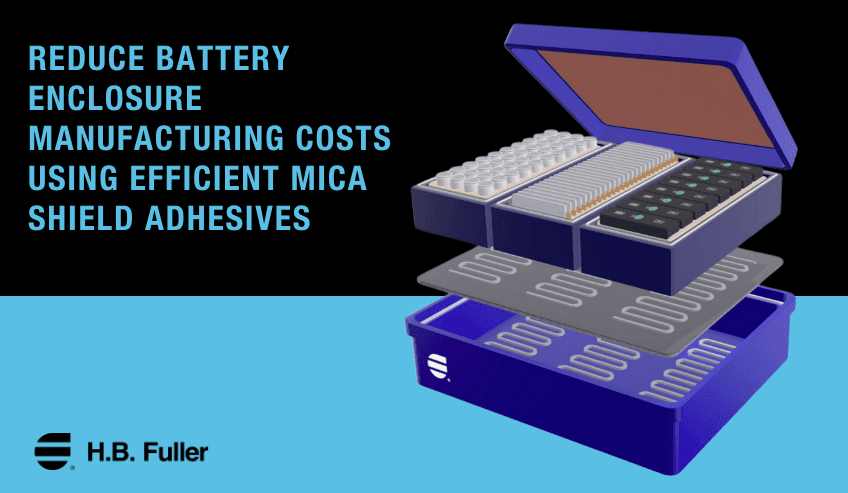

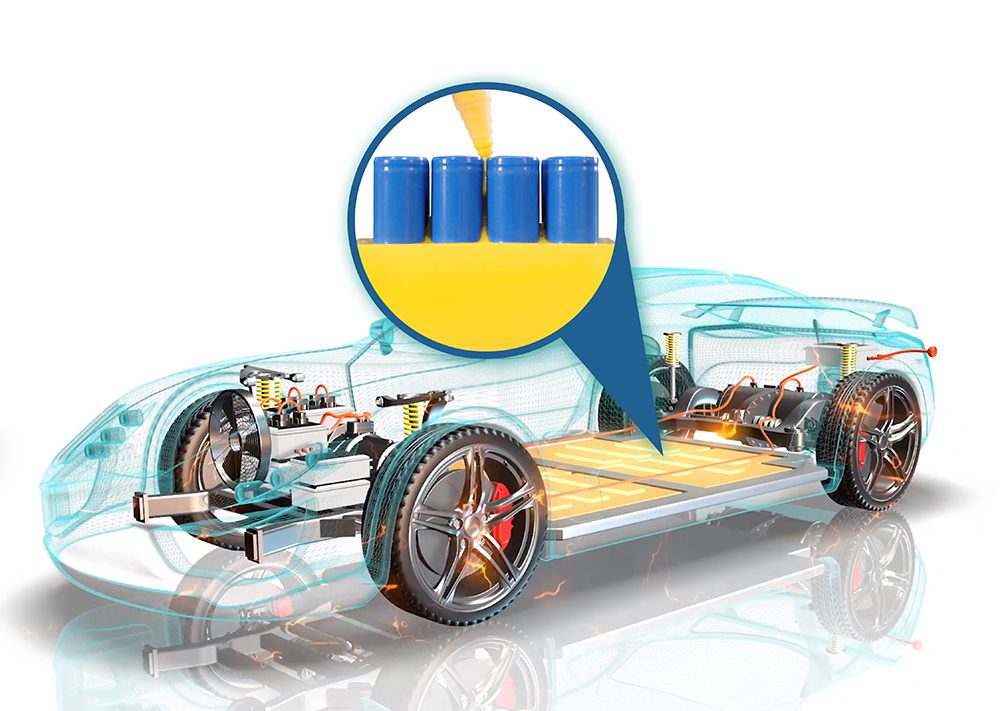

Heat generated in high-density automotive battery packs is often managed by connecting battery cells and/or modules to a heat sink via a thermal interface material (TIM). The TIMs promote heat conduction by displacing any air that resides within the large gaps and microscopic rough surfaces that exist between the substrates to be bridged.

In practice, battery manufacturers typically use one of two types of TIM products, a cure-in-place liquid-dispense gap filler or a pre-cured thermal pad (also called gap pad), each of which has their pros and cons.

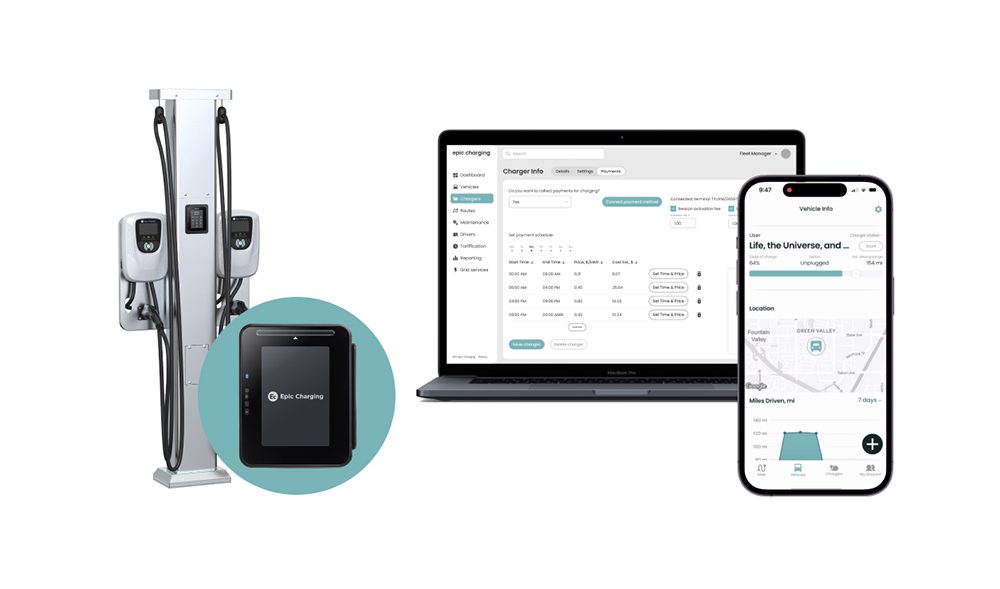

LORD recently conducted a study to compare the thermal impedance of gap fillers versus commercially available thermal pads having equivalent bulk thermal conductivities. Learn more during the free webinar hosted by Charged on August 7, 2018, 2:00 PM EDT.

Data from this and future studies on battery pack thermal performance will enable designers to develop more efficient and cost-effective battery packs.