LSIS was established in 1974 and spun off from the LG Group in 2003. The company business focus is on green energy electric power equipment and automation. LSIS has led the Korean electric power equipment market for the last 40 years and with the expansion of the renewable energy market, the company’s particular focus is on DC device commercialization for the solar and electric vehicle markets.

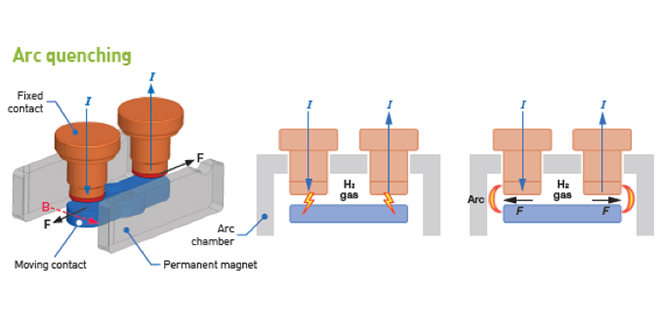

HVDC Relays are used to supply and cut off the DC power, by opening and closing contacts by an actuator. Arcing that occurs when the DC power is cut off may cause damage to the contacts and surrounding components, so the arc should be extinguished as quickly as possible in the desired direction. The LSIS HVDC Relay is a product of power field technology and know-how gained over the last 40 years. It has excellent electrical durability, compact size, with low noise and features a permanent magnet and hydrogen inside for optimal arc extinguishing.

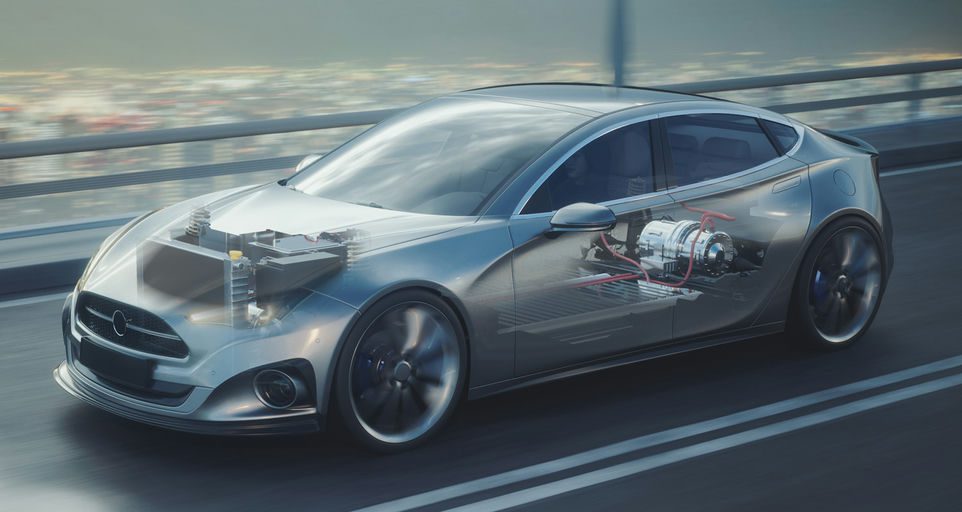

HVDC Relay in Electric Vehicles (GER series)

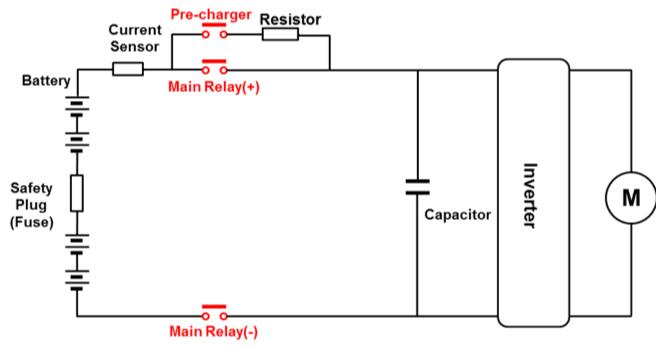

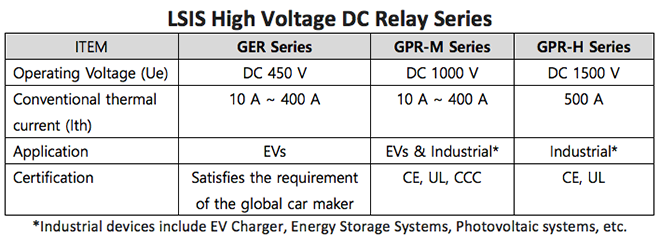

LSIS’ HVDC Relay came to the market for the first time in electric vehicles (HEV, PHEV, EV). Now they are mass produced to keep up with demand from well renowned global automobile manufacturers, who have accumulated trust in LSIS’ products. The HVDC Relay, applied to an electric vehicle, is installed between the vehicle battery and the inverter to cut off the charge and to discharge the DC power of the battery. It is also used between the external charger and the vehicle battery. Applied products are from the general electric relay (GER) series with a rated voltage of DC 450 V and rated current 10 A ~ 400 A.

GER series

Electric vehicle application system

HVDC Relay expanding high voltage application (GPR-M, GPR-H series)

LSIS has been developing mass production of their GPR-M (DC 1000 V class) and GPR-H (DC 1500 V class) series. Generally, as the rated voltage increases, the size of the product must be increased to ensure insulation. However, the GPR-M (1000 V) series is implemented in the same size as the GER (DC 450 V) series, thus improving the customer’s space utilization. The GPR-M and GPR-H series are equipped with the same hydrogen barrier as the GER series.

As the battery capacity of the vehicle increases, the rated voltage is increased and the external charge is expanded. Therefore, it is required to monitor the increase of the DC relay voltage and the On/Off of the contact point.

GPR-M series has a rated voltage of DC 1000 V, 10 A ~ 400 A. The GPR-M400 can be used to check contact On/Off by monitoring the auxiliary contact. These products are all UL, IEC, CCC certified.

GPR-H series has a rated voltage of DC 1500 V, 500 A and an auxiliary contact. They are all UL and IEC certified. In addition, an advantage is that the GPR-H series can be used in a system in which bi-directional blocking, such as reverse blocking or charge / discharge of a system can occur, by applying a bi-directional magnet arc extinguishing structure.

Demand for the LSIS HVDC Relay is expected to increase exponentially with the continued global trend of expansion of renewable energy. The rapid charger for an electric car switches the AC to DC to supply electricity to the vehicle and the HVDC relay is used to supply and cut off the power. ESS, a system for storing electricity, uses a HVDC Relay between the battery and PCS. The HVDC Relay is used for On/Off of solar modules in PV systems.

Based on its achievements in DC 450 V electric vehicles, LSIS will continue to commercialize HVDC relays to DC 1000 V and DC 1500 V for electric vehicles and chargers and will continue as a leader in the renewable energy market.

For more information on LSIS HVDC Relay and Contactors, click here.