Experts discuss the special concerns when designing battery technology for marine environments.

There is growing worldwide demand for electric-powered vessels and for broader electrification in maritime operations, particularly in ports. Consider the Ports of Los Angeles and Long Beach, for example. Air pollution from those ports is a top concern for environmental and public health officials. Maritime-related air pollution directly affects people in nearby residential communities, and maritime emissions are a big factor in California’s constant struggles to meet federal air quality standards.

The DOT’s Maritime Administration (MARAD) recently held a two-day public workshop to “share information and gather input related to the application of high-power batteries in maritime transportation.” Sixty-one people attended the event, with additional participants linked via webcast. The goal was to develop and enhance a knowledge base that would advance electric and hybrid vessels, to help fill the gaps in marine battery applications.

The meeting was attended by representatives from across the maritime sector, including battery manufacturers, ship owners and operators, shipyards, ports, domestic and foreign regulatory agencies and, importantly, standards organizations – the entities that actually develop the testing and documentation that, when followed, provide confidence of safety in vessel designs and operation.

For MARAD, a key theme was that “addressing the gaps and pursuing innovation in this area will require strong collaboration among battery manufacturers, power management and integration experts, and designers, ship owners and operators.”

Many countries, as well as many US states and cities, are moving to control carbon and greenhouse gas emissions. Mariners need to be aware of new rules and regulations. Equally important, MARAD writes, the increasing costs of marine fuel, particularly low-sulfur diesel fuel, are driving the maritime industry towards investigating the use of alternative energy and multi-source energy hybrid technologies.

MARAD writes that high-power battery technology is being viewed more broadly as a potentially viable technology in maritime applications. However, application in vessels is complex – recent accidents with lithium-ion batteries highlight the need for additional work, hence the workshop.

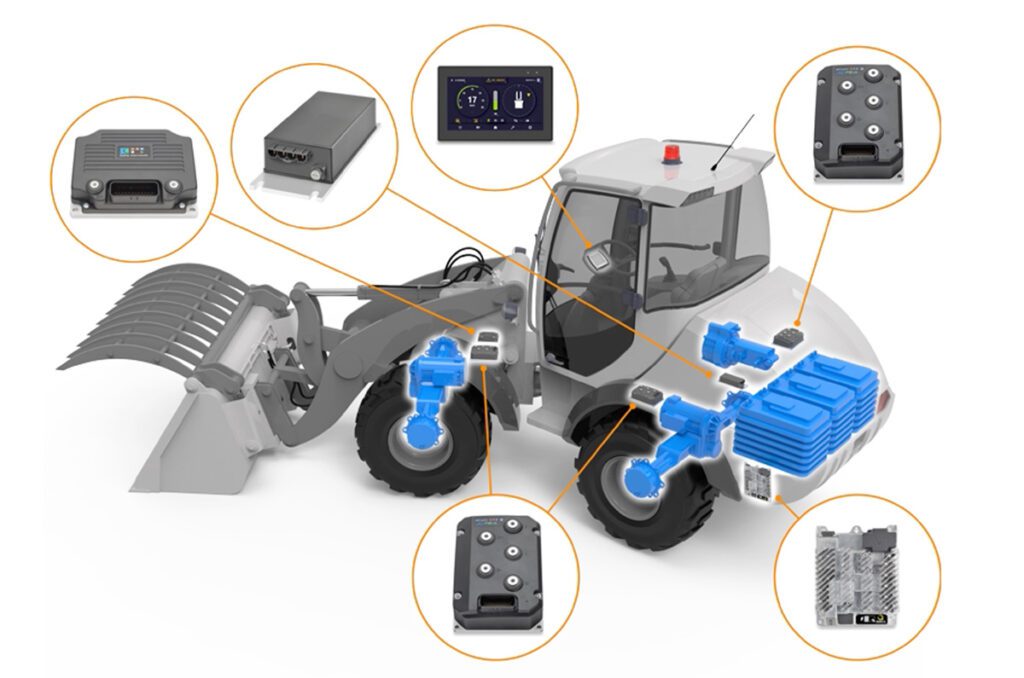

Vessels and boats demand a lot of power. On ships, for safety, battery power really needs to be thought of as a systems challenge. John Warner of EnerDel presented a session on battery cell design for marine applications. Indianapolis-based EnerDel designs, builds and manufactures lithium-ion energy storage solutions and battery systems with a focus on heavy-duty transportation.

Warner addressed design considerations, starting with safety. He said, “The natural position for a battery is to be fully discharged,” a dynamic with “inherent dangers and risks.” Battery management systems (BMS) oversee and control interconnected cells. Warner described a BMS as the “computer that runs the batteries, typically a distributed system.” A BMS coordinates input and gives direction, communicating with the vessel about power application and, critically, available power and how long it will last.

Thermal control is critical. Engineers use the term “thermal runaway” to describe uncontrolled increasing temperature within a battery, possibly spreading among multiple batteries, resulting in explosion or fire. There are no cookie-cutter solutions. Answers depend on the use of the vessel and even its location in the world. A system that works in the Arctic Ocean may not be applicable in the Indian.

Moisture – remember, this is for marine environments – is another concern with Li-ion batteries. “Moisture does horrible things to the Li-ion content,” Warner said.

There are always novel and heightened concerns when contemplating new technology in a marine environment. Vessels and boats are singular, isolated systems, compact, relatively dense and enclosed. Marine designers know this – in just about every aspect, vessels require development and analysis different than land-based vehicles or buildings. This is particularly true with fuels. Consider, for example, the risks of pumping, storing and using liquefied natural gas on a vessel that is berthed next to a major city.

Warner said that the next steps in addressing vessel electrification are likely to take a case-by-case approach, with specific reviews evaluating exactly how a boat or vessel will be used. He mentioned a project in England in which the capabilities of an electrified vessel would match the work demands. Ferries are viewed as a likely initial application because ferry operations can take advantage of infrastructure and electric supply capabilities.

Internationally, vessel electrification has advanced more than in the US. Workshop speakers referenced current e-boats now in use in Europe, mostly in the Scandinavian countries. Brian Baker of Corvus Energy described some of his company’s work with European ferries and sightseeing craft. Corvus provides energy storage solutions for marine, oil and gas and port applications. Baker noted that regarding vessel size, “there is essentially no limit. It comes down to making sure you are doing your homework and putting in the pack sizes applicable for you.” Baker said that fuel savings on one European excursion route were around 15%, prompting company officials to install similar systems in three additional ships.

As usual, apples-to-apples comparisons are important. Benefits in Europe may not emerge in the US, for many reasons. European electrification policies have fundamental differences compared to the US. General price subsidies, for example, can skew individual outcomes. Some initial costs in Europe are covered by low-carbon energy funds, which are unavailable to American operators. Some vessels and projects are considered to be part of a national highway system, and are eligible for public funding. Still, Baker’s reference is important. Ship designers worldwide are working on these problems now. E-vessels are in the pipeline. Money is not usually invested in a lost cause.

The Red and White Fleet is one US company that’s investing in electrification, and it’s carefully approaching questions about costs and benefits. Red and White, established in 1892, offers sight-seeing tours in the San Francisco Bay area. Vice President of Operations (and boat captain) Joe Burgard is leading R&W’s evaluation of electric vessels – he was one of the presenters at the MARAD workshop.

Burgard described some of the difficult issues in an electric/diesel analysis. There are many factors, starting with the cost of diesel, and how much it might, or might not, change. R&W is building a plug-in hybrid vessel. Even different charging rates – time-of-use rates – affect cost outcomes. “What is challenging is that each variable will change the picture considerably,” Burgard says. He said that any analysis really has to be vessel- and route-specific. “The economics will change based on the energy demand of the vessel, the time to charge, the source and cost of electricity, even the battery chemistry.”

All of R&W’s investment in electrification is out-of-pocket – it has not received any state or federal planning or assistance grants. The biggest factor for R&W is the commitment of the company’s owner, who believes there will be a payoff for this research. Nevertheless, it still takes hard work and tough choices to get there.

At the end of the MARAD conference, next steps were divvied up among a number of groups. The Coast Guard, of course, is involved – work continues on a policy letter to provide guidance on vessel design, systems and operation.

The American Society for Testing and Materials (ASTM) has formed an industry task group to develop some of the required standards for marine battery technology. Det Norske Veritas-Germanischer Lloyd (DNV-GL), is a European certification and classification society. ASTM and DNV-GL organized a Joint Development Project to develop rules for the safe application of Li-ion battery technology.

In a recent interview, Michael Carter, MARAD’s Director, Office of Environment, was asked how this work has progressed in the last year. His assessment: work is ongoing and on track. Professional societies are meeting. Although there is no one federal agency formally designated for follow-up, Carter did say MARAD personnel, and people from DOT and DOE, are involved.

Carter pointed out that there is external demand to resolve battery safety questions. Ship owners are building new vessels that include battery technology. They will need to use these new assets. Drydock is not an option.

This article originally appeared in Charged Issue 34 – November/December 2017 – Subscribe now.