“Any product that uses less power and has high torque in a small package could be of interest to the EV space,” LORD’s Edward Conner told Charged. We were discussing the company’s electromagnetically actuated rotary band brake technology, and we naturally asked a lot of questions about its potential applications for EVs.

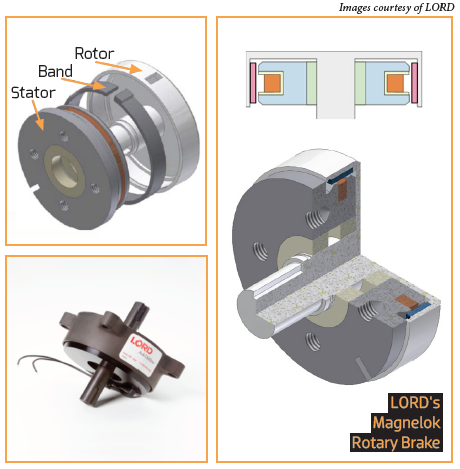

The core of the product line, which LORD calls Magnelok, is a flexible steel band wrapped around a coil. When the coil is energized, the band is pulled around the core electromagnetically. The band is stimulated by a pulse width modulation (PWM) driver and can react in a millisecond with near instantaneous movement and locking, allowing for high repeatability and accuracy.

LORD also touts the technology’s low power consumption, potential to downsize applications where it fits, and zero off-state resistance, which allows for a fail-safe return to default position.

Finding the right applications

LORD originally developed Magnelok for the manufacturing and automation industry. The company saw industrial potential to replace large-capacity motors that are often sized for applications that include a lock and hold position. The idea was that a motor enabled with the Magnelok rotary band brake could be significantly reduced in size, while achieving equal hold-position behavior using much less power. In other words, instead of using the typical motor control techniques to maintain a certain rotor position, Magnelok could mechanically lock and hold it using friction.

More recently, LORD began to explore automotive applications for its rotary band brake. The company is currently developing Magnelok for automotive-grade liquid cooling circuit valves.

“Most cars today still use a valve technology that was developed decades ago,” explained Conner. “It is a paraffin wax valve that’s designed to open at a certain temperature, 85 or 95 degrees, for example.”

Conner is a business development director at LORD, with a focus on automotive electro-mechanical systems. He explained that when a car needs a cooling system with more control, engineers typically use valves that are actuated by electric motors. Research has shown that if an ICE cooling system can maintain a higher engine temperature within a tighter band, it’s possible to reduce greenhouse gases and improve fuel economy by about 3 or 4%. You can also shorten the startup time to reach optimal temperature with more precise control, because you keep the valve closed longer.

The commonly-used paraffin valves are typically designed to hold an engine within a 10-degree variation, while more active valves can reduce that variation down to 1 to 2 degrees.

Magnelok enters the discussion as a low-power alternative to holding a valve in precise position. “It can be a butterfly valve, shutter valve, ball valve or anything you want to actuate,” said Conner. “To be clear, Magnelok doesn’t do the actuation, it is basically a strong lock and hold. So instead of using the electric motor power to hold position, they could use Magnelok to reduce the size of the motor and power requirements. It consumes low parasitic power with PWM control and can generate significant forces based on scalability. We think it will be a great solution for more precise control of ICE coolant flow and thereby better management of the engine temperature, which helps achieve efficiency goals.”

Interest from EV builders

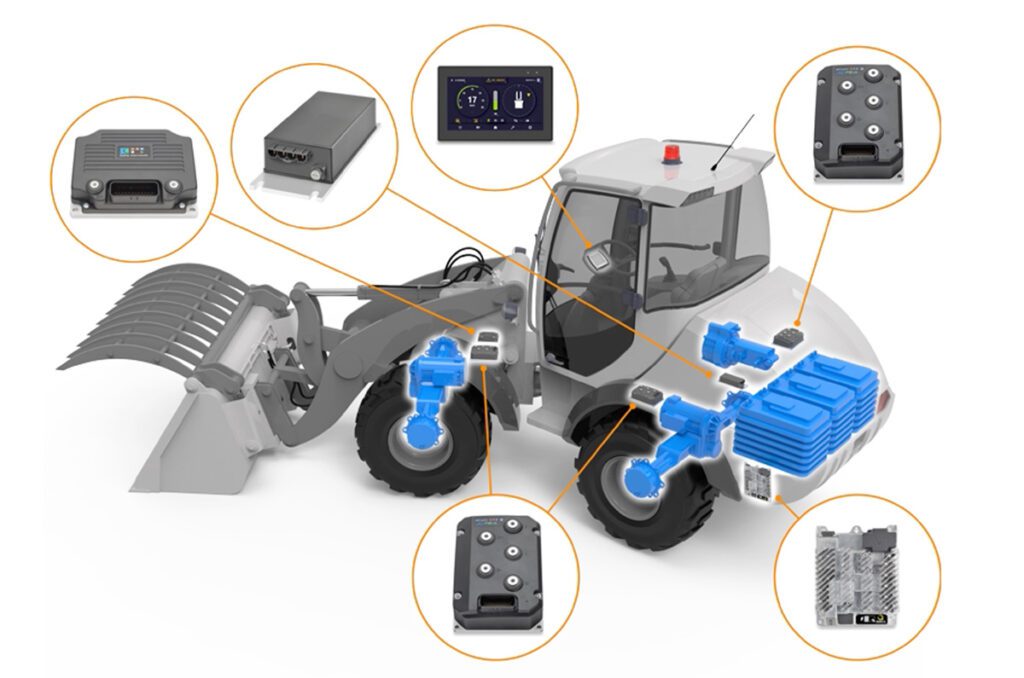

LORD believes there may also be significant advantages to using Magnelok in automobiles without engines. For example, many EV battery packs are also designed with liquid cooling loops to precisely control the temperatures. Maintaining ideal operating conditions is critical for many types of Li-ion cells to increase their lifespan and reliability.

“The technology has a lot of attributes that match the needs of EVs,” said Conner. “Low parasitic power, high power output, heat resistance, harsh environment resistance, scalability…and it’s fail-safe.”

Because Magnelok will release its lock when it’s de-energized, Conner says it could be used in a system that is designed to flood a battery pack in the event of a problem. So, if there is a total system power loss, the natural state of the valve is open – which helps keep the battery temperature down. “When it’s in an off state there is close to zero friction, so it will create marginal drag on the system,” said Conner.

LORD also thinks that Magnelok could help simplify systems with multiple liquid cooling loops, particularly in hybrids or PHEVs. In some cases there are three different liquid circuits – high-temperature for the engine, mid-range for the power electronics, and low for the battery pack. Magnelok could offer creative engineers more options. For example, it’s possible to replace many valves with a single 3- or 4-way valve that can actively change position.

Open to ideas

Development of new applications for Magnelok is still in the early stages, and the company says it’s actively seeking partners in the auto industry.

“We know that for some electric motor applications that require a lock and hold, incorporating Magnelok can reduce the required motor size by as much as 50%,” said Conner, “which also translates to energy savings. So, we’re interested in partnering with anyone who thinks this technology might provide a good solution to a problem that they haven’t been able to solve.”

This article originally appeared in Charged Issue 30 – March/April 2017 – Subscribe now.