The all-electric underpinnings that the VW Group will use to build dozens of EVs

A few weeks before the end of 2019, if all goes according to plan, the first Volkswagen I.D. Neo electric car will roll off the assembly line at the company’s plant in Zwickau, Germany. Different versions will offer ranges from 160 to perhaps as much as 300 miles. It will be Volkswagen’s first long-range electric car, and the company expects it to sell in high volumes.

The C-segment (compact) I.D. Neo hatchback is just the first of more than two dozen all-electric models to be launched by the VW Group. It won’t be the first long-range EV offered by the group; that honor will be claimed by the Audi e-tron when it goes on sale this spring and summer in various markets around the world.

However, the I.D. Neo will be the first mass-priced long-range EV the group offers. Executives have confirmed over the years that their goal is a starting price roughly the same as that of a high-end diesel Golf, which carries a premium of a few thousand dollars over its gasoline-engine equivalent.

The VW Group says these EVs will roll out in quick succession – it has promised two dozen by 2025, when the company expects to sell 1 million all-electric vehicles out of its global sales total of 10 million or more. The VW Group will sell them under four separate brands in Europe alone: Volkswagen, yes, but also Audi, SEAT and Skoda. There will be electric models for several China-only brands as well. The total projected cost: 80 billion euros.

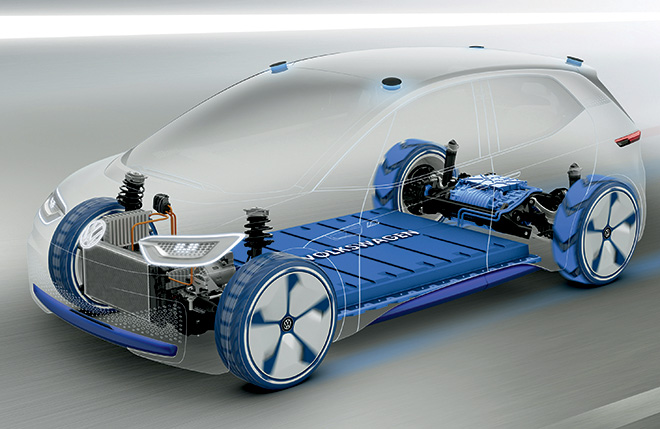

All these vehicles will share a common set of underpinnings, known as the MEB architecture. This is a set of frontal crash structures, motor mountings and suspension assemblies, and a floor structure under which is located a wide, long, flat battery pack. Known as a “skateboard” arrangement, it’s the same layout used by Tesla and likely all future high-volume battery-electric vehicles. MEB can accommodate rear- or all-wheel drive, a variety of vehicle types from sleek sedans to tall, boxy utility vehicles and vans, and various wheelbases with lower- or higher-capacity batteries.

The VW Group currently builds up to 4 million vehicles with transverse combustion engines each year on its shared MQB architecture, which underlies everything from the Polo subcompact hatchback (smaller than a Golf) to the seven-seat Atlas mid-size crossover built and largely sold in the US.

The MEB architecture is meant to be to electric cars what MQB is to transverse front-wheel-drive vehicles: a single, highly flexible set of underpinnings intended to cut costs by using shared components across multiple brands, vehicles and segments.

October 2015: decision point

The plan for such a platform was hatched during an executive retreat in October 2015, one month after the VW diesel-emission cheating scandal was revealed by the US EPA. The full scope and cost of the scandal had yet to emerge, but even then some of the newly appointed executives viewed it as an opportunity for a corporate reset.

At that point, Volkswagen had only two years of experience with low-volume production of two battery-electric vehicles, both adapted from conventional models.

The Volkswagen e-Golf, sold in Europe and North America, sited sections of its battery pack in various locations across a highly modified MQB platform. Launched in 2014 with an EPA range of 83 miles from a 24 kWh battery pack, it got far higher-capacity cells for the 2017 model year, giving it a range of 125 miles. Volkswagen’s other EV was the e-Up, an adaptation of its European Up minicar, fitted with a 18 kWh battery that delivered a real-world range of 60 to 90 miles.

But MEB was to be a dedicated platform, allowing every vehicle to offer at least 200 miles of range from a battery with a capacity of 48 kWh or greater. The pain of adapting combustion-engine vehicles to accommodate smaller powertrains but bulky batteries not anticipated in the design would end. Instead, dozens of models could be created as optimized electric vehicles from the start.

The first concept car, known simply as the Volkswagen I.D., appeared a year later at the 2016 Paris Motor Show. The battery-electric five-door compact hatchback offered the interior volume of a larger mid-size sedan like the VW Passat. That was due not only to the flat under-floor battery pack, but also the lengthy cabin that was made possible by pushing the wheels to the corners of the car to allow as much room as possible within the wheelbase for the battery pack.

To the surprise of many, VW’s engineers put the primary traction motor in the rear. It was a decisive step away from the transverse front-wheel-drive layout that was standard for all small and medium-size vehicles since the pioneering 1959 Morris Mini showed what packaging efficiencies were possible by turning the engine sideways and powering the front wheels.

For a single-motor EV, however, Volkswagen says handling and road-holding are better with rear-wheel drive. Analysts note that it also avoids the use of costly constant-velocity joints to accommodate pivoting front drive wheels. When all-wheel traction is required, the front structures are designed to accommodate a second motor between the front wheels. VW says AWD versions are likely to be offered only with the largest battery option, which can better supply the current demanded by two motors operating simultaneously.

Exposing the naked platform

With less than a year left to go until production, the company has started to show the naked MEB platform to the media. Charged saw the rolling chassis during its first North American appearance, at the 2019 Chicago Auto Show in February.

Matthew Renna, VP of E-mobility for VW North America, ran through the history of VW’s decades of experimenting with electric vehicles, the stats and specs for its modern era of EVs, and what it expects from battery technology over the next few years.

He noted that its battery modules are designed to accommodate any form of prismatic or pouch cells, though the company is not focused on using large numbers of small cylindrical cells. That is the Tesla approach, but it remains unique to that company.

Renna walked through historic and projected rates of battery improvement and, unusually, offered precise numbers. The cells used in the 2014 e-Golf provided 230 watt-hours per liter and 140 Wh per kilogram, he said, while the cells VW will use in 2020 are rated at 700 Wh/l and 300 Wh/kg. At the same time their price (in dollars per kWh) has fallen steadily, though he declined to give specific costs.

The result is a car with a range of 200 miles or more that can be mass-priced, or close, with the threat of range anxiety significantly abated. Nissan’s experience with its 40 kWh LEAF, introduced for 2018, indicates that 150 miles of range may be enough for Europe – where that model has been extremely popular – but that 200 miles is the minimum necessary for North America, which has little or no mass transit of the sort Europeans take for granted between city pairs.

The Volkswagen I.D. Neo is expected to come to market with three battery capacity options. While VW hasn’t given exact specs, they’re anticipated to be about 48, 55, and 62 kWh. Ranges on the European WLTP test cycles were quoted at 330, 450 and 600 km, which might translate to EPA ratings of roughly 160, 210 and 250 miles.

Neo, Crozz, Buzz, Vizzion, and more

Although VW’s I.D. Neo will go into production before the end of this year, North American buyers won’t see it in showrooms. The hatchback will be sold only in Europe, where that format is most popular. In the US and Canada, we’ll have to wait until 2021, when a compact crossover – with the concept name I.D. Crozz – goes into production.

That car will first be built in Europe, then enter production in 2022 at VW’s plant in Chattanooga, Tennessee, for the Americas, and perhaps other markets. Putting the I.D. Crozz into that plant requires an investment of $800 million, Volkswagen says, and will create 1,000 new jobs onsite, and many more at suppliers.

Beyond that, in 2022, VW expects to introduce the model that may have created the most buzz of any VW electric. Known as the I.D. Buzz (pronounced “bus” in German), it’s an all-electric rebirth of the classic and much-beloved Volkswagen Bus of the 1960s. The company has big plans for this vehicle, which is a joint development between Volkswagen’s vehicle division and its commercial-truck group.

That indicates that we’ll see not only passenger versions, but also panel vans and very possibly pickups and other models, echoing the multiple versions of the old “Type 2” or “Bulli,” as Germans called it. Certainly the response to the I.D. Buzz design on the auto-show circuit and during a prototype drive we took part in was nothing short of ecstatic, with a couple of fans running right through the middle of a photo shoot to ask questions about what it was and when it was coming.

For 2023, the company is promising a large Volkswagen sedan, possibly a replacement for the luxury VW Phaeton that bombed in the US but took the brand far further upscale in Europe than it had ever been. The I.D. Vizzion concept may be destined mostly for Chinese buyers, as sedans with generous rear compartments remain in high demand there. After that, in 2024, comes a large utility vehicle, likely an Atlas-sized electric SUV with seven seats.

Considerably earlier, in 2021, a small Audi (“A SUVe”) will be built on the MEB architecture – just as the brand’s A3 compact sedan is built on VW Golf and Jetta MQB underpinnings. That Audi is likely previewed by the Q4 e-tron concept at this year’s Geneva Motor Show.

Obviously, the Volkswagen Group is hardly the only large automaker to plan a skateboard chassis for hundreds of thousands of battery-electric vehicles a year by the early 2020s. It is, however, the company that has spent the most time talking about its plans – partly out of necessity, to distract from news reports and court decisions around its diesel scandal.

The openness is also partly pride, however. VW Group firmly believes it has a chance to become one of the world’s major electric car makers by 2025, catching up to Nissan, Tesla and GM.

Perhaps its executives took to heart the words famously attributed to Winston Churchill: Never let a good crisis go to waste.

This article appeared in Charged Issue 42 – March/April 2019 – Subscribe now.