Believe it or not, we may have a BEV SUV turf war on our hands. Many of the major automakers have announced plans to produce all-electric crossovers, including Mercedes, Volvo, Hyundai, Kia and Volkswagen – not to mention the onslaught startups like SF Motors, Faraday Future, Byton and Rivian. The all-electric Audi e-tron SUV is expected to start European deliveries as early as this fall.

However, the only challenger to the Tesla Model X on its way to the North American market is the 2019 Jaguar I-PACE BEV crossover SUV, which is to begin shipping as early as September.

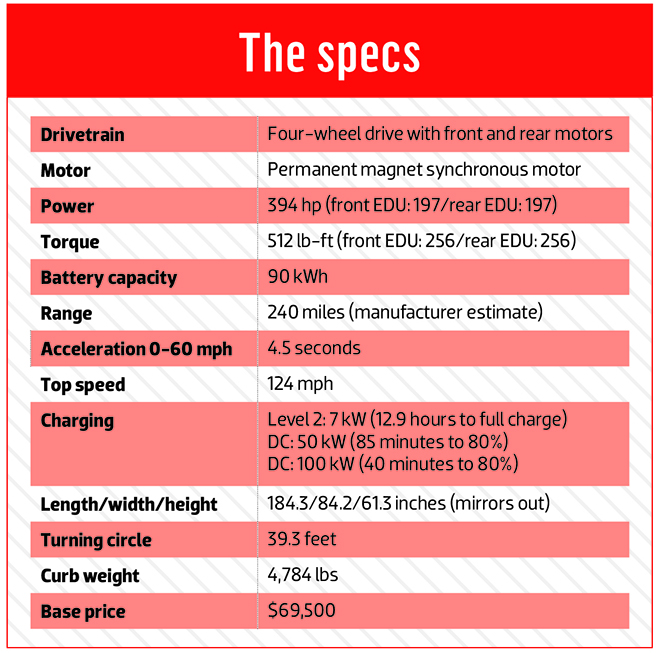

At a base price of $69,500 (up to $85,900 fully loaded), the I-PACE offers an iconic brand name, an attractive and distinct design, and no questions about the company’s ability to produce at scale. Jaguar Land Rover (JLR) uses the contract Magna Steyr plant in Austria to produce the I-PACE, as well as its ICE counterpart, the E-PACE, and the company has promised to invest $1.5 billion to build out its North American infrastructure of dealerships, charging facilities, and customer services over the next five years.

JLR’s introduction of crossovers and SUVs to its product line two years ago spiked its global and US sales, and now the I-PACE could test the resiliency of BEV luxury SUVs in the market, as JLR continues to expand its horizons. The company has partnered with Waymo to add the I-PACE to its driverless fleet. The first Waymo self-driving I-PACE will begin tests later this year, and Waymo plans to purchase 20,000 I-PACEs by 2020.

Customer pre-orders for the I-PACE began in March. It has a shorter range (240 miles) than the Model X and uses the CCS charging system, rather than a dedicated network of Supercharger stations, but one wonders if the cachet of the Jaguar name combined with a lower price will help the I-PACE continue to spread the EV flame across crossover-happy America.

As I discovered first-hand in June, the I-PACE is an incredibly satisfying car in terms of visual appeal, driving performance, comfort and technological amenities. The two-decade Jaguar veteran Ian Callum oversaw the I-PACE’s design over a span of more than four years, bringing together design and engineering teams who sought to tie together Jaguar’s historic legacy, modern advancements and EV-specific innovations throughout the vehicle’s mechanical and electrical engineering, exterior design and in-car tech.

A balance of power

Even though the I-PACE is a pure EV, the exterior and internal design and engineering teams wanted to maintain the “core Jaguar DNA attributes” of its look and feel, said Simon Patel, Powertrain Senior Program Manager for the I-PACE. From a performance angle, that meant balanced and precise handling and immediate response to driver inputs.

Achieving that in a large, long-range EV presented some challenges, such as getting the center of mass as low as possible for optimum vehicle dynamics. Because the 90 kWh lithium-ion battery makes up 30% of the total vehicle mass, it’s situated in the base of the chassis, which was also the best place for it from a safety/crash perspective. The body structure of the car is 94% aluminum, with just a bit of steel in key areas that needed extra strength.

Integrating the battery into the body also helped Jaguar achieve a high torsional stiffness of 36 kiloNewtons per degree, making it “the stiffest Jaguar we have ever made,” according to Patel.

Another challenge related to NVH (noise, vibration and harshness). “Without the noise of the ICE and transmission, the I-PACE’s overall sound levels are 6-8 dB less than our next quietest cabin,” Patel said. “Road noise and other noises can be heard and felt that the engine would otherwise mask.”

The I-PACE team developed a unique optimized NVH package that includes a double-isolated EDU (electric drive unit) mounting system on both the front and rear axles. That system also complements the car’s very low center of gravity and 50/50 weight distribution between the front and rear axles, which the team wanted for its performance dynamics.

“The key was to balance battery capacity vs overall vehicle height vs drag co-efficient,” Patel said. “We think we got the correct recipe.”

The I-PACE has two permanent magnetic motors – designed in-house by Jaguar’s electric machine experts – integrated into the front and rear axles. A torque vectoring system uses the foundation brakes to give the I-PACE side-to-side torque vectoring, and its front and rear Intelligent Driveline Dynamic system delivers that torque smoothly, with precise control over the speed and pull to each of the four wheels.

Another important strategy was to manage the heat generated from the motors, powertrain and battery. The I-PACE has three automated cooling systems integrated to boost the car’s performance and range.

The cabin and battery operate on a similar cooling circuit, because people and batteries tend to like the same temperature of around 20 degrees Celsius. The motors and power electronics use a separate system that maintains a higher temperature range optimal for those components. On colder days, heat from the motor and battery heat up the cabin to save electrical energy, which Patel said can improve the range up to 35%.

In its strongest regenerative braking mode, the I-PACE’s motors deliver up to 0.4 g of deceleration. But when the driver is less concerned with energy conservation, the performance-oriented Dynamic mode increases the responsiveness of the front pedal, sharpens the steering for more precise turning, and applies greater levels of control and feedback to the suspension.

The function of form

For allegiance to Jaguar’s legacy, and for the drag co-efficient part of the balance equation Patel spoke of, the I-PACE exterior design team concentrated on both aerodynamic function and aesthetic form. Simon Tovey, JLR’s Exterior Creative Design Manager, explained that the I-PACE’s look was inspired by the Jaguar C-X75 hybrid-electric concept supercar, which he worked on developing from 2010 to 2012. The C-X75 itself largely took inspiration from the Jaguar XJ13 prototype race car from 1966.

“We always have something we can look back on and reinterpret,” Tovey said. “We just looked to the past, but then came up with new ideas. The new ideas on this were purely functional.” The C-X75 design contributed to what Tovey called the “muscular, shapely haunches” of the I-PACE, as well as to its sense of movement that the general Jaguar aesthetic has portrayed.

However, as an electric car with two motors sitting between the wheels, the I-PACE didn’t need the long hood – or bonnet, as the Brits prefer – that many Jaguar models have. That allowed the front seats to move forward, which in turn allowed the rear occupants to have more space, and also gave the I-PACE the appearance of an exotic mid-engine sports car, Tovey said.

While many electric cars don’t have a grill in front, the I-PACE does. Its grill makes it recognizable as a Jaguar but also serves a dual function. There is a radiator under the hood, so air passing through the grill helps cool the radiator for the batteries and other electric components, and also plays a part in the larger emphasis on aerodynamics.

Air moves through and over the grill, through and over the hood, up over the roof, and stays attached before moving through the rear spoiler, which Tovey said is actually more like a wing. There is also a side intake where air goes through into a wheel arch and is released down through the sheer side of the car. Finally, rather than the tapered rear section seen on many Jags, the I-PACE has a high, square, boxy back end, because, as Tovey explained, for aerodynamics you want a hard, sharp edge in the rear, so that air flows off all in one area, reducing turbulence.

All this emphasis on aerodynamics helps get the I-PACE’s drag coefficient as low as 0.29. “Aerodynamic efficiency in electric car terms equates to mileage almost one-to-one,” Tovey said.

At the same time, while the I-PACE’s height is rather low for a crossover SUV, whether you have the glass roof or metal roof, it is a thin top, allowing for more space. Tovey’s proud of the fact that the I-PACE offers comparable cabin space to the Jaguar 2018 XJ luxury sedan in a footprint comparable to that of the 2018 Porsche Macan ICE compact SUV.

Well-connected car

Today’s EVs are still cars first, but computers second. The I-PACE features JLR’s updated Touch Pro Duo system with twin HD dashboard touchscreens, and all the navigation, connected home and remote-control features you find in luxury vehicles, along with a 4G Wi-Fi hotspot for up to eight devices and some EV-specific advantages.

A dedicated EV screen shows nearby charging stations, and can route the GPS to the nearest one. There is artificial intelligence (AI) built into the I-PACE computer, and over time its machine learning will pick up the patterns of a driver’s style, to better determine the available range and offer power usage estimates for each waypoint on the current navigation map.

AI-assisted Smart Settings are brand new to the I-PACE. They connect to the Bluetooth-enabled key fobs, so for every driver of the car, the system will learn the preferred seat settings, zoned climate control settings, favorite radio stations, etc, and pre-condition the I-PACE for that driver as the key fob approaches. Selma Bambur, JLR Connected Car Future Technology Strategist, said it takes about two weeks for the I-PACE AI to learn a driver’s settings, driving style, etc.

You can also check the I-PACE’s range, set a time window for charging, find out if there’s enough power to complete pre-determined trips and more, either from a smartphone app or by talking to an Amazon Echo (Alexa) device when you’re away from the vehicle. Conversely, from inside the I-PACE, you can control your smart home devices such as the Philips Hue LED lights and Nest or Wink home control gadgets.

The I-PACE’s technological bells and whistles extend to new safety and driver-assist features as well. The updated Autonomous Emergency Braking System alerts the driver through the driver-side display to pedestrians, cyclists and other hazards, and attempts to nudge the car out of the way if the driver fails to take action. With the front-facing and other cameras around the I-PACE, the computer stitches together a 360-degree bird’s-eye view on the 10-inch dash display to help with tricky parking and other maneuvering.

Bambur noted that the connected car initiatives take their direction from customer requests and behavior trends, which mean a great deal when serving the dual niches of EVs and luxury SUVs. So the decisions to add six USB ports and three 12 V sockets to the I-PACE, as well as choosing the 35 InControl apps for the dashboard touchscreen, which vary by region, must all balance customer desires with the constraints and concerns of the overall engineering teams.

“The dynamics between the different teams are actually quite fun,” she said. “We like to challenge each other to get the best out of the system and push each other to deliver something special. We all come in with our initial visions and try to get as close to them as possible, while always putting what customers want first.”

This article originally appeared in Charged Issue 38 – July/August 2018 – Subscribe now.