China has announced a cut to its subsidies on new energy vehicles (NEVs), effective immediately. It’s been something of a rollercoaster ride for the subsidies of late. In 2015, the government announced plans to end the subsidies this year. In January, it said there would be “no significant cuts” this year. In March it confirmed… Read more »

Search Results Found For: "MIT "

Workhorse C-Series electric delivery trucks earn EPA Certificate of Conformity

Electric truck maker Workhorse Group (NASDAQ: WKHS) has been around for a while—Charged wrote about the company’s plug-in pickup back in 2017—and it continues to make steady progress. Now the company has announced that its new C-Series electric delivery trucks have each received an EPA Certificate of Conformity, confirming that the new vehicles conform to… Read more »

MIT team develops novel solid electrolytes and pure lithium anodes

New research from MIT could lead to batteries that pack more power per pound and last longer. A new paper co-authored by Yuming Chen and Ziqiang Wang at MIT explores the idea of using pure lithium as the battery’s anode. The design is part of a concept for developing safe solid-state batteries by dispensing with… Read more »

California and 7 other states commit to faster electrification of medium- and heavy-duty vehicles

California is joining with seven other states to develop an action plan to put hundreds of thousands more zero-emission trucks and buses on the roads. This new medium- and heavy-duty vehicle collaborative effort will be implemented through the multi-state ZEV Task Force, and will be facilitated by the Northeast States for Coordinated Air Use Management… Read more »

Rivian’s VP of Propulsion: Thermal issues are the dominant limiting factor for maximizing EV performance

Charged recently chatted with Rivian’s VP of Propulsion Richard Farquhar to learn more about the design and development of the company’s unique electric platform (read the whole story in our upcoming issue). Farquhar spent 15 years as Powertrain Director at McLaren Automotive, designing and developing some of the highest-performance propulsion systems in the world for… Read more »

Lamborghini and MIT patent a new material for supercapacitors

Lamborghini and the Massachusetts Institute of Technology (MIT) have patented a new synthetic material that the carmaker hopes will serve as the technological base for a new generation of supercapacitors. The two organizations began working together in 2017, when they produced the Terzo Millennio concept car. With support from Lamborghini’s Concept Development Department, a research… Read more »

MIT researchers demonstrate new way to make thin-film lithium-rich ceramic electrolytes

Researchers at MIT have come up with a new pulsed laser deposition technique to make thinner lithium electrolytes using less heat, which they say promises faster charging and potentially higher-voltage solid-state lithium-ion batteries. Key to the new technique for processing the solid-state battery electrolyte is alternating layers of the active electrolyte lithium garnet component (LLZO)… Read more »

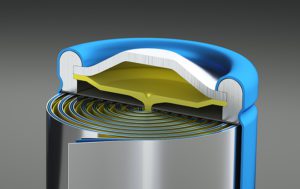

Sumitomo and Kansai University develop technology to generate power from static electricity in tires

Sumitomo and Professor Hiroshi Tani of Kansai University have developed a new technology to generate electricity from the rotation of a tire. By installing a power generating device (or Energy Harvester) inside a tire, researchers were able to convert static electricity into clean energy. The new device, which Sumitomo calls the ‘SMART TYRE CONCEPT’, takes… Read more »

Mayors from 127 cities commit to purchase over 2,100 EVs by 2020

Mayors from 127 cities joined the Climate Mayors EV Purchasing Collaborative during the Climate Mayors Summit in Honolulu, Hawaii last month, committing to purchasing more than 2,100 EVs by 2020. To assist in the transition towards electric school buses, the Collaborative announced it will place a competitive bid on electric school buses by the end… Read more »

Proterra and Mitsui create $200-million credit to scale battery leasing program for electric buses

Electric bus manufacturer Proterra has partnered with Japanese conglomerate Mitsui to create a $200-million credit to scale up Proterra’s battery leasing program. Proterra customers will be able to purchase an electric bus and lease the batteries over the 12-year lifetime of the bus. Through the battery lease, Proterra says the initial capital expense for the… Read more »