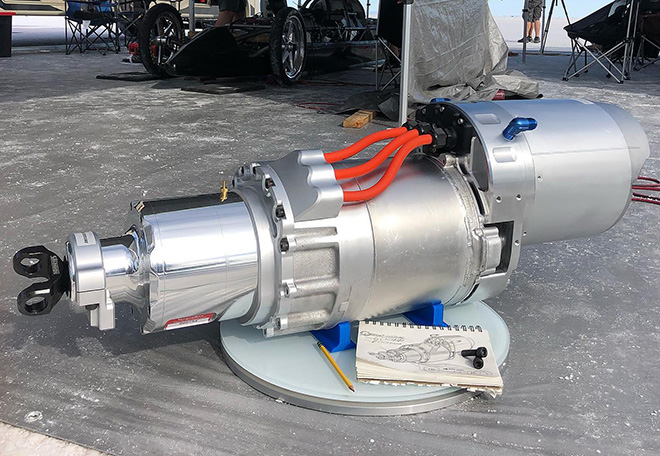

EV conversion one-stop shop EV West has announced a new Tesla crate motor kit designed to convert V8 muscle cars to EVs. The drop-in package consists of a complete Tesla drive unit, including inverter and mounting brackets. “Our new Revolt Tesla crate motor mounts to your small block motor mounts and attaches directly to your… Read more »

Search Results Found For: "DOE "

Soteria licenses battery tech designed to eliminate thermal runaway

Soteria Battery Innovation Group has exclusively licensed and optioned a technology developed by the DOE’s Oak Ridge National Laboratory (ORNL) designed to eliminate thermal runaway in Li-ion batteries due to mechanical damage. The technology complements Soteria’s existing battery safety technology. Soteria Battery Innovation Group is a technology development and licensing company that has formed a… Read more »

The monster that wouldn’t die—varied reactions to GM’s electric Hummer unveil

EV fans tend to be divided into two groups: Greenies and Car Guys, and reaction to GM’s upcoming Hummer EV has, unsurprisingly, been divided along those lines. Hummer good Most of the media is ecstatic over the new machine. Many are praising its “bad-ass” looks (GM says it wanted to make it look “less military”… Read more »

3 factors that impact gap filler reworkability in EV battery packs

Sponsored by Parker LORD The design of electric vehicle battery packs may vary among manufacturers but commonly, the battery is attached to its cooling plate not only with fasteners but also thermally conductive polymeric materials called gap fillers. Gap fillers can outperform thermal pads in this application to achieve lower thermal impedance, as the gap… Read more »

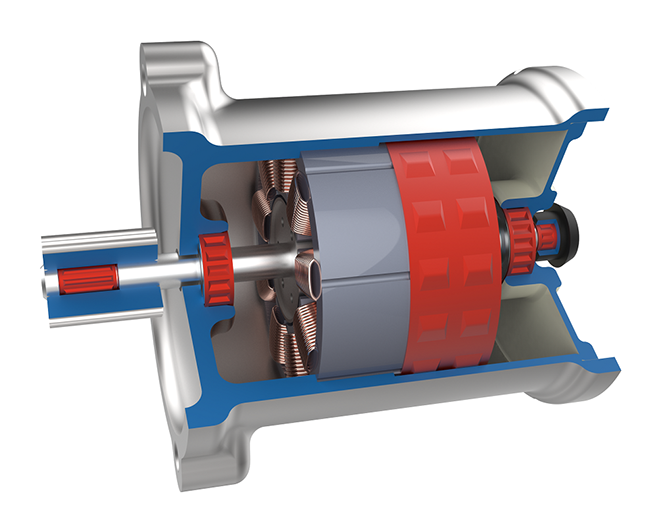

Saint-Gobain’s RENCOL Thermoclad bi-metallic tolerance ring for EV motors

Saint-Gobain‘s first bi-metallic tolerance ring, RENCOL Thermoclad, is designed to help automotive OEMs and Tier 1 suppliers achieve heat transfer properties in EV motor applications, cutting down on the manufacturing time and space required by adhesives or heat-shrink press-fit. The company says RENCOL Thermoclad’s thermal transfer coefficient is competitive with leading adhesives, yet does not… Read more »

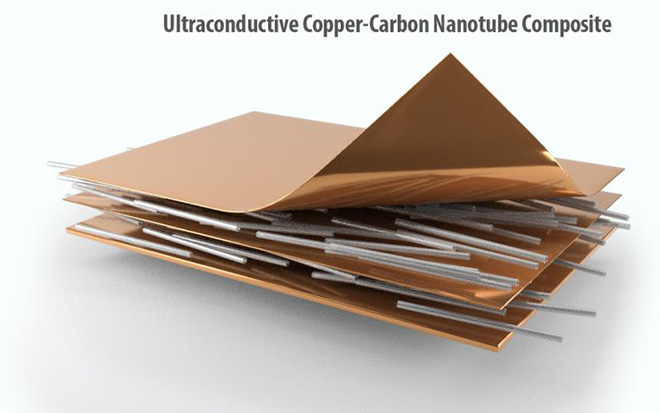

New composite material increases current capacity to rev up EV efficiency and range

Scientists at Oak Ridge National Laboratory (ORNL) have used new techniques to create a composite that they claim increases the current capacity of copper wires, providing a new material that can be scaled for use in ultra-efficient, power-dense EV traction motors. The research is aimed at improving the performance and life of components such as… Read more »

Tesla Model 3 logs 100,000 miles with little reported battery capacity loss

There are plenty of high-mileage Teslas on the road, but so far we’ve heard from few Model 3 owners who’ve passed the 100,000-mile mark. Kazi Imam is one driver who’s passed that milestone, and he recently told his story to Electrek. Imam logged 100,000 miles on his 2018 Model 3 Long Range in just over… Read more »

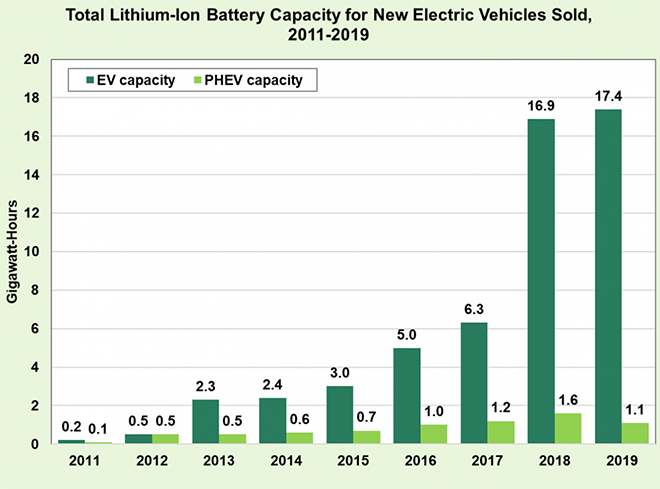

Li-ion battery capacity for new EVs sold in the US reached a record high in 2019

Battery electric vehicles (BEVs) captured a record amount of total plug-in vehicle battery capacity sold in 2019, with 17.4 gigawatt-hours of total capacity. Plug-in hybrid electric vehicles (PHEVs) accounted for a smaller portion of total vehicle battery capacity due to their lower sales volumes, and because they require smaller battery packs than BEVs. PHEV sales… Read more »

Volkswagen ID.4 and Nissan Ariya bring EV drive to compact crossovers…chasing Tesla Model Y

Can new electric entries in a hugely popular segment convince US buyers to buy EVs from Nissan and VW as family vehicles? Two new battery-electric models from major global car brands are about to bring electric cars into a category where they’ve been notably absent: family crossover utility vehicles. The 2021 Volkswagen ID.4 and 2022… Read more »

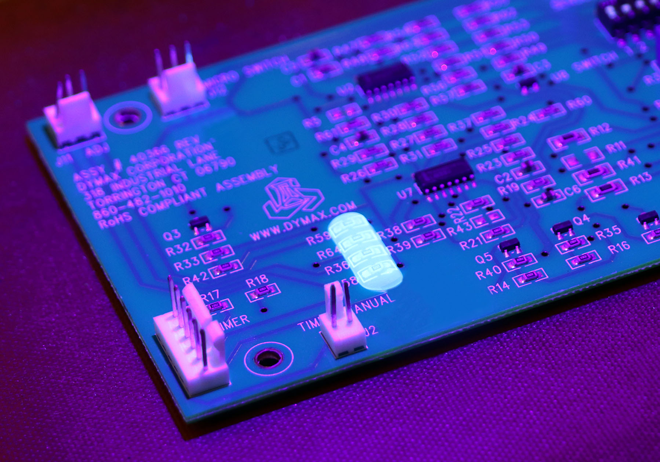

Encapsulant provides excellent corrosion protection of critical PCB components in EV electronics (Whitepaper)

Sponsored by Dymax Corporation By Dr. Aysegul Kascatan Nebioglu and Chris Morrissey Components on printed circuit boards or electronic modules in electric vehicles are often required to be covered with polymeric encapsulants to protect them against environmental conditions such as moisture, chemicals, and rapid and extreme temperature changes, while providing mechanical support and electrical insulation…. Read more »