At the upcoming Battery Show Europe, German adhesive specialist Henkel will showcase its latest advances in adhesives, functional coatings, thermal management and sealing solutions, which the company calls “key enablers of safer, more efficient and more sustainable EV batteries.” “At Henkel, we are collaborating closely with industry partners to push the boundaries of EV battery… Read more »

Search Results Found For: "henkel"

Henkel launches silicone-free gel to protect ADAS components from thermal degradation

German chemical company Henkel has launched its Bergquist Liqui Form TLF 6500 CGel-SF to deliver heat dissipation for autonomous driving systems. By delivering a higher level of conductivity, the thermal curable gel is designed to prevent performance degradation and protect the sensitive ADAS domain controllers that enable real-time vehicle decision-making from heat degradation and damage…. Read more »

Henkel opens Battery Test Center in Düsseldorf

German chemical and consumer goods company Henkel has opened a new Battery Test Center at the company’s headquarters in Düsseldorf. The new facility is an addition to Henkel’s Battery Engineering Center, which opened in 2023 with the launch of the Battery Application Center. The facilities are part of Henkel’s efforts to strengthen its position as… Read more »

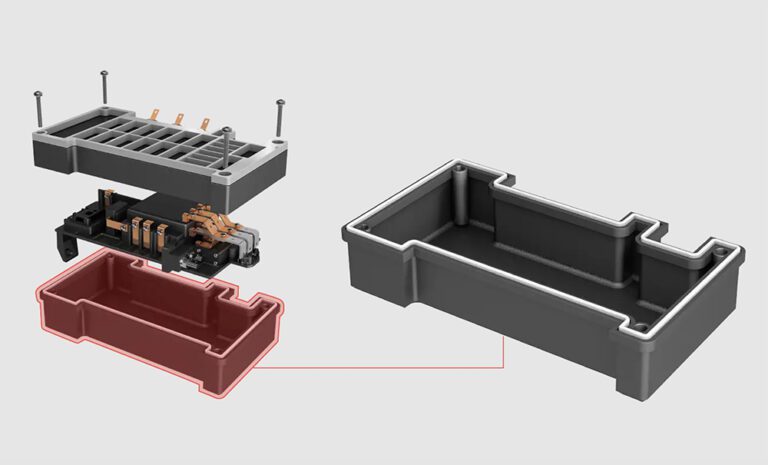

Henkel’s new automotive potting solutions safeguard electronic components’ performance, durability and longevity

Adhesive and sealant specialist Henkel has added three new products to its portfolio of dedicated potting adhesives, each tailored to meet specific challenges. Potting of sensitive electronic components such as ECU connectors, sensors and e-motors protects them from moisture and exposure to common automotive fluids. Henkel’s new potting products are designed to enable more efficient… Read more »

Henkel’s high-performance battery sealing technology

Sponsored by Henkel. Delivering Innovtion, Expertise and Reliability For Battery Manufacturers Globally After decades building a reputation for performance and reliability among global OEMs and component suppliers, Henkel has expanded its broad portfolio of adhesives, sealants, and functional coatings to serve EV manufacturers with innovative solutions across the EV segment. When it comes to ensuring… Read more »

Henkel develops REACH-compliant silicone material for sealing electronic component modules

Automotive adhesives maker Henkel has developed a new material for silicone liquid gasketing for automotive electronic components. Loctite SI 5972FC is a one-part RTV silicone form-in-place-gasket (FIPG) solution that expedites electronic module sealing. The liquid silicone material adheres to metal and plastic surfaces and is designed to pass OEM leak or blow-out pressure tests immediately… Read more »

Henkel’s new injectable thermally conductive adhesive for EV battery systems

Henkel Adhesive Technologies, a maker of automotive adhesives, sealants, thermal materials and functional coatings, has extended its portfolio of solutions for EV battery systems with a new injectable thermally conductive adhesive. The new adhesive, Loctite TLB 9300 APSi, provides both structural bonding and thermal conductivity in the battery system. Henkel says the new product has… Read more »

Henkel introduces new protective coatings for battery housings

German chemical company Henkel has introduced two new coatings designed to protect battery housings from heat and fire in case of a thermal runaway event. The company says, “When applied to battery packs, the coatings help to inhibit and delay the spread of fires to protect the passengers as they evacuate the vehicle.” Loctite EA… Read more »

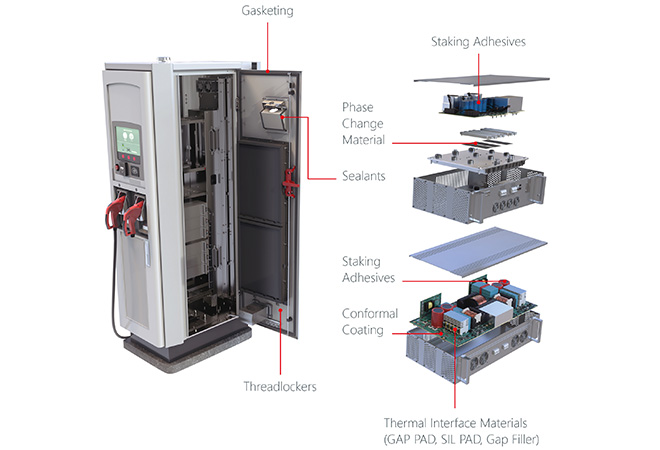

Henkel’s new thermal materials and sealants for EV chargers

German chemical company Henkel offers a range of materials designed to increase the reliability, safety and cost-effectiveness of EV chargers. According to Henkel, its Bergquist phase change, GAP PAD and gap filler thermal interface materials provide effective heat dissipation and support reliable operation in the power modules of EV chargers. The company’s sealants and Sonderhoff… Read more »

Henkel introduces liquid gap filler for automotive and power conversion electronics

Henkel has announced the debut of its latest thermal interface material (TIM), Bergquist Gap Filler TGF 7000. The liquid TIM combines high thermal conductivity of 7.0 W/mK with a dispensing speed of 18 grams per second. The material is designed for applications such as advanced driver-assistance systems (ADAS), power conversion systems, electric pumps and electronic… Read more »