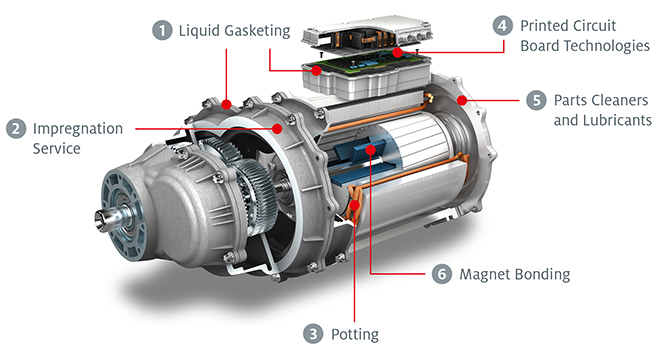

Engine and powertrain specialist Henkel aims to solidify its e-mobility commitment by investing in several new EV-oriented manufacturing processes. Henkel has chosen to focus on developing several adhesive and liquid gasketing materials as well as PCB technologies, part cleaners and lubricants. Here’s the breakdown: Liquid gasketing: Henkel offers a wide range of different gasketing technologies. Recent… Read more »

Search Results Found For: "henkel"

Webinar: Using simulation solutions to accelerate material development for battery systems

As a leading provider of advanced materials for EV battery systems, Henkel has taken a pioneering role in utilizing advanced modelling and simulation to develop materials for its e-mobility portfolio. In this webinar, we will highlight the importance of simulation in improving materials and achieving better designs for innovative EV battery systems. We will explore… Read more »

Whitepaper: Sustainable processing for next-generation vehicle manufacturing

Sponsored by Henkel. Learn how Henkel’s processing solutions enable sustainable, next-generation vehicle manufacturing across the value chain, from molten metal to final component Discover how Henkel’s sustainable processing fluids enable significant environmental benefits across key stages of the vehicle lifecycle, including the raw material stage and during customer manufacturing processes. Gain insights into metal-forming lubricants,… Read more »

Enabling dry battery cell manufacturing with conductive coatings (Whitepaper)

Sponsored by Henkel. With an innovative approach to lithium-ion battery electrode manufacturing, dry battery electrode (DBE) processing eliminates the solvent-based slurries traditionally used in lithium-ion battery production. By implementing DBE technology, battery manufacturers can enhance production efficiency, reduce energy demand, and decrease overall environmental impact while improving electrode performance and reducing battery production costs. DBE… Read more »

Metal Processing Solutions to Enable Production, Performance And Sustainability Advantages Of BEV Bodies And Components

Moving toward an electric future in the automotive industry requires component suppliers and automotive manufacturers to meet an ever-growing list of must-haves. • Production must be efficient and streamlined to meet burgeoning demand• Performance must meet the highest standards to ensure safety and durability across rigorous conditions• Sustainability must be an integral part of both… Read more »

A deep dive into the power electronics used for battery testing (Webinar)

The need to quickly increase EV battery testing capacity is making validation labs harder to manage and forcing engineering teams to explore ways to sustainably scale up their test lab operations. Battery cyclers that are flexible, open, and connected are critical to achieve the scale needed in modern battery validation labs. Join this webinar, presented… Read more »

Adhesives & Bonding Expo returns to Michigan in June 2024

Spark connections: Fuel your automotive applications Adhesives & Bonding Expo, the largest, free-to-attend trade fair and conference for industrial bonding products and manufacturing in North America, is returning for its fourth edition from June 25-27, 2024, in Novi, MI. Register to attend and you’ll gain easy access to the co-located Foam Expo taking place in… Read more »

Thermal potting for EV components (Whitepaper)

Sponsored by Henkel. With the dramatic growth anticipated in the electric vehicle industry, manufacturers and component suppliers alike are vying for position in performance, range, cost efficiency, durability and reliability. Thermal potting materials, while often unseen, play an important role in heat management – a significant factor in achieving these objectives. As such, designers and… Read more »

Enabling next-generation EV batteries with thermally conductive adhesives

Sponsored by Henkel. With the rapid growth and adoption of electric vehicles, OEMs and battery manufacturers are turning to technology to make EVs more efficient and affordable. Engineers, seeking ways to optimize the battery and its components for long range, safety, and reliability, are turning to the “Cell-to-Pack” configuration for next-generation battery designs. Most of… Read more »

Controlling thermal conditions for DC fast charging reliability (application challenges)

Sponsored by Henkel Market Situation Consumers are embracing EVs as a proactive investment in environmental responsibility and CO2 emission reduction. Though EV sales are on the rise, significant infrastructure hurdles remain. While single-phase charging is readily available, continued EV sales growth and consumer confidence (driven by convenience and reliability) will require broad access to fast… Read more »