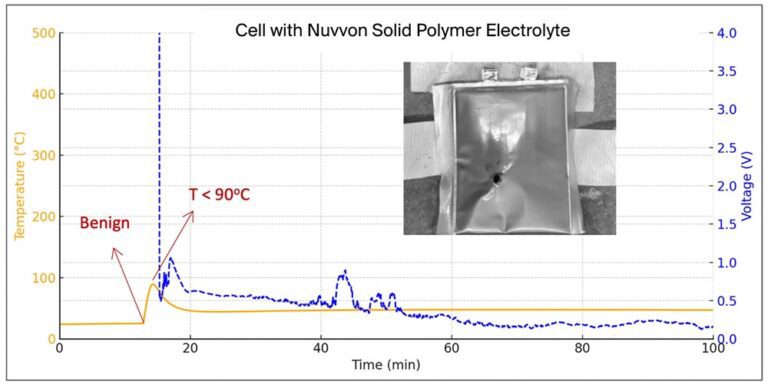

US solid-state battery technology developer Nuvvon’s polymer electrolyte has passed a series of nail penetration tests, which create a short circuit inside the cell to determine if the battery catches fire or explodes. In two sets of tests, which were conducted at The University of Texas at Austin (UTA), traditional 1 Ah cells of commercial… Read more »

Search Results Found For: "graphite"

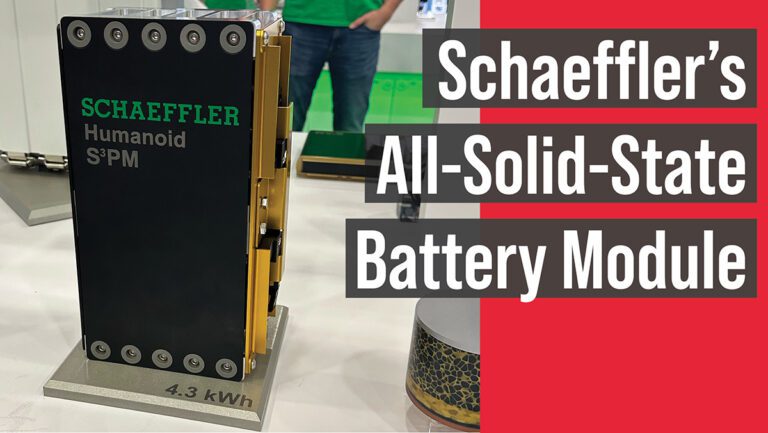

Video: Schaeffler’s all-solid-state battery module and other eMobility innovations

At this year’s Battery Show in Detroit, Charged spoke with four of Schaeffler’s subject-matter experts to explore the company’s innovations in electrification and energy storage. The discussion began with Rashid Farahati, Vice President of the Corporate Competence Center for the Americas. Farahati explained that while solid-state batteries promise higher energy density, safety and faster charging,… Read more »

Ateios Systems and Kodak unveil solvent-free battery electrode manufacturing process

Battery electrode supplier Ateios Systems has teamed up with materials and chemicals manufacturer Kodak to demonstrate a high-speed, solvent-free production process for the manufacturing of high-energy electrodes for EV batteries. The system, powered by Atelos’s RaiCure platform, reaches a coating speed of 80 meters per minute, which the companies say is nearly three times faster… Read more »

Sunrise secures US patent for lithium battery anode material prep method

Sunrise (Guizhou) New Energy Material, a subsidiary of Chinese graphite anode material manufacturer Sunrise New Energy, has been granted a US patent titled Preparation Method of an Anode Material for Lithium-Ion Batteries. The method improves the initial Coulombic efficiency and power performance of graphite composites for next-generation high-energy and high-power lithium-ion batteries, according to the… Read more »

Sila begins automotive-scale silicon anode production to boost domestic EV battery supply chain

Sila has announced it has started operations at its new large-scale silicon anode manufacturing plant in Moses Lake, Washington. The site, which spans over 600,000 square feet on a 160-acre property, is designed to supply advanced battery materials for EV manufacturers and other battery-powered applications. The facility aims to transition silicon anode technology from laboratory… Read more »

Amprius SiCore battery cells power unmanned aircraft systems in Ukraine

The Astero ISR, a battle-tested unmanned aircraft system designed and built by Nordic Wing, a Danish-owned fixed-wing drone manufacturer, has been in use by Ukrainian forces since early 2023, and many improvements to the drone have been based on feedback from Ukrainian soldiers These drones are built for a hardened environment. The Astero ISR is… Read more »

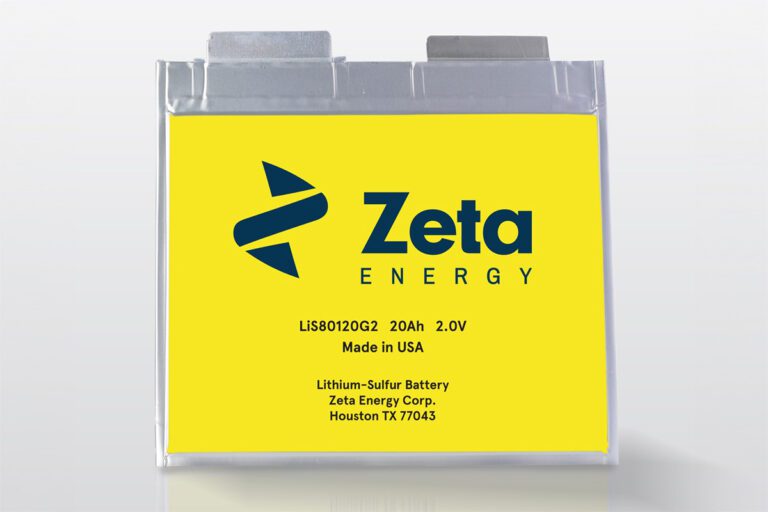

Zeta Energy makes a breakthrough in lithium-sulfur battery technology

Cheap, abundant and sustainable. Sulfur may not be the most glamorous of elements—some may associate it with rotten eggs, stinky well water, or even the devil, as invoked in a country preacher’s fire-and-brimstone sermon. But as a component of an EV battery cathode, sulfur has a lot to offer. The yellow stuff is lighter and… Read more »

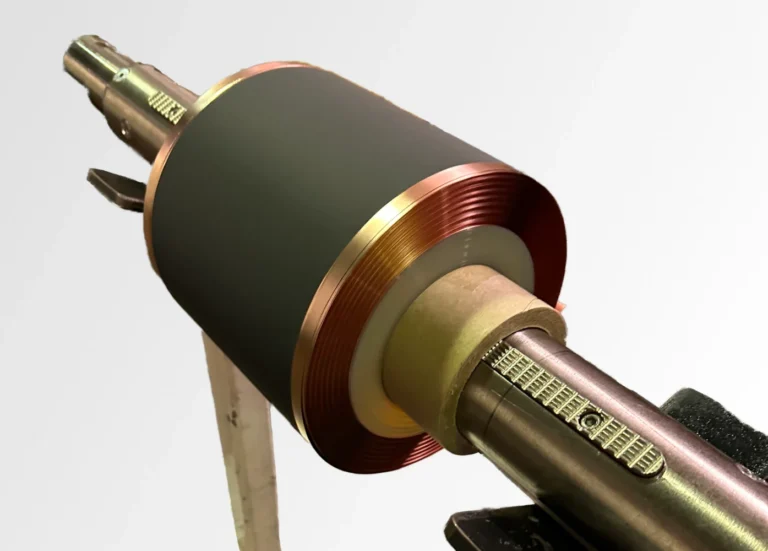

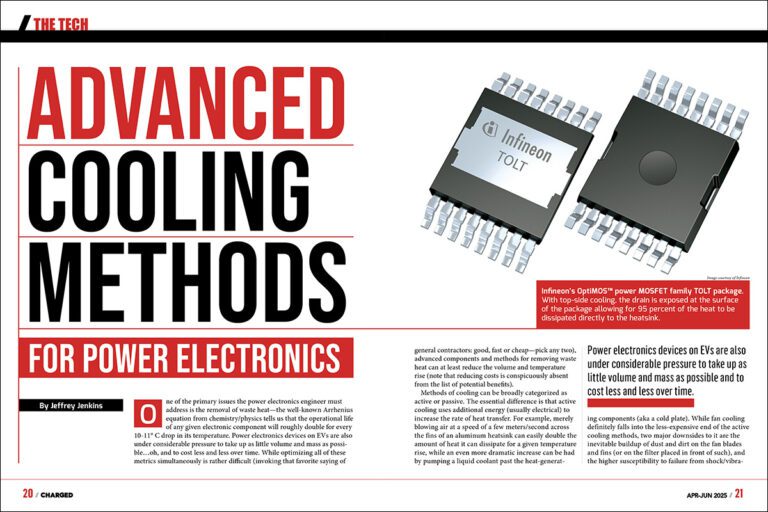

Advanced cooling methods for power electronics

One of the primary issues the power electronics engineer must address is the removal of waste heat—the well-known Arrhenius equation from chemistry/physics tells us that the operational life of any given electronic component will roughly double for every 10-11° C drop in its temperature. Power electronics devices on EVs are also under considerable pressure to… Read more »

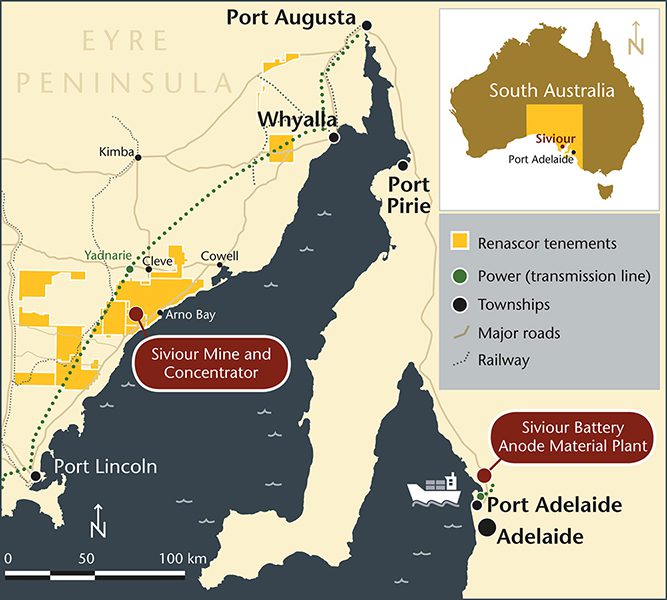

Renascor receives regulatory approval for Australian battery anode material facility

Australian mining company Renascor Resources has received provisional development authorization from South Australia’s Minister for Planning for its proposed commercial-scale battery anode material manufacturing facility in South Australia. The authorization is required under South Australian legislation for impact assessed developments for the company to be able to construct the downstream portion of the vertically-integrated battery… Read more »

Lucid partners with US battery mineral producers for EV manufacturing

US EV manufacturer Lucid Motors has joined with critical mineral producers Alaska Energy Metals, Graphite One, Electric Metals and RecycLiCo to launch the Minerals for National Automotive Competitiveness Collaboration (MINAC). The consortium aims to help accelerate the development of domestic critical mineral resources and the procurement of minerals for use in automotive manufacturing by US-based… Read more »