Thermal interface materials (TIMs) and adhesives play a critical role in the thermal management of EV charging infrastructure. They help to transfer heat away from the heat-generating components of charging stations, such as the power electronics, charging handles, and the optional battery backup. This helps to ensure that the charging stations operate efficiently and reliably…. Read more »

Search Results Found For: ""Parker LORD""

Charged Virtual Conference on EV Infrastructure: new December 2023 session topics announced

New session topics for the December 2023 Charged Virtual Conference on EV Infrastructure are out now. This virtual event will span all things EV charging in two main tracks: Featuring speakers from organizations including: The free-to-attend conference will be broadcast December 4 – 6, 2023, featuring live presentations, interactive Q&As, on-demand webinars, and whitepaper downloads…. Read more »

Webinar: Assessing technologies for dielectric protection for battery cells and cooling plates

With the significant growth and development of battery pack technologies, manufacturers of EVs are placing an increased emphasis on pack design optimization seeking lighter weight and more compact solutions to gain additional energy density and reduce cost. In our webinar, we will discuss our evaluation of the dielectric protection, process application advantages and disadvantages, edge… Read more »

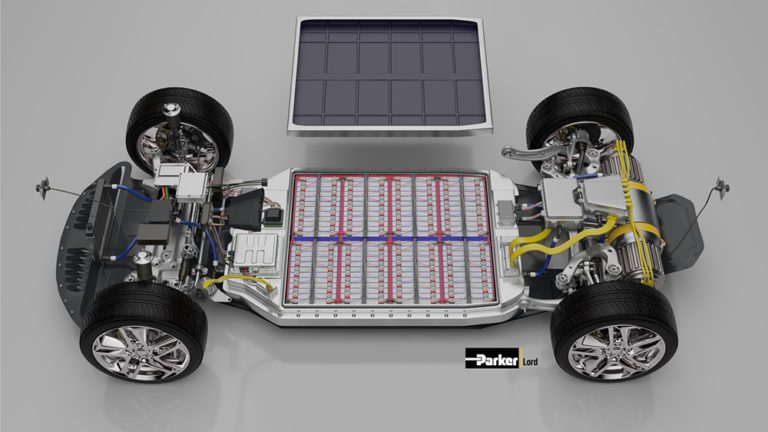

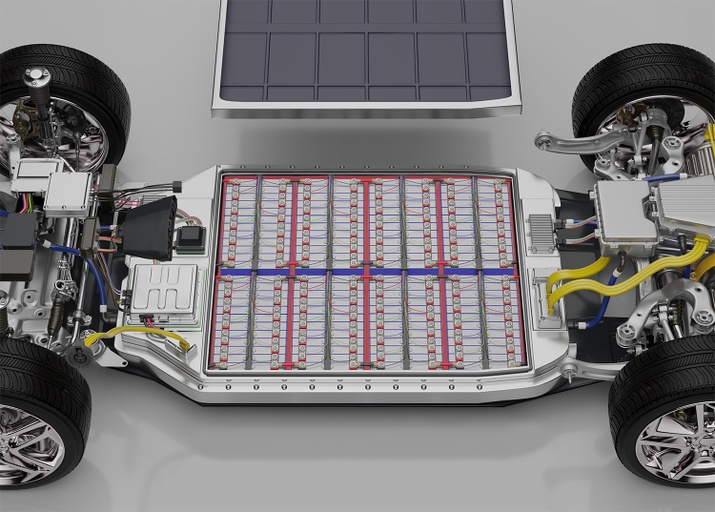

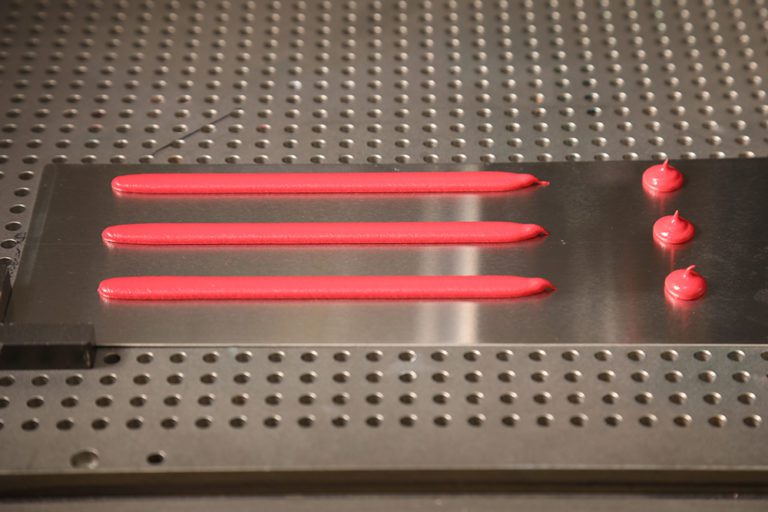

Assessing technologies for dielectric protection of battery system components

Sponsored by Parker Lord. With the growth and development of battery pack technologies, manufacturers of electric vehicles (EV) place greater emphasis on pack design optimization, seeking more compact solutions to improve energy density and reduce cost. In the assembly of high-voltage battery packs, dielectric protection is critical. Manufacturers often apply dielectric materials to the battery… Read more »

5 electric vehicle trends seen in 2022

Sponsored by Parker LordJust over a decade ago, a report by IDTechEx predicted 1.5 million battery-electric vehicle (EV) sales by the start of 2021—a prediction seen by many as overly optimistic. Yet, it turned out to be a significant underestimate by more than half. And there is no sign of EV sales slowing in 2022. In fact, Bloomberg… Read more »

Thermal Conductive Adhesives For Next Generation Cell-to-Pack Configurations

Cell-to-Pack is the direct bonding of individual battery cells to the battery pack’s cooling plate, and it’s a new trend in the EV market. It improves performance by providing higher pack energy density, improved part complexity, lower thermal loads on the battery pack, and simpler, lower-cost manufacturing of packs. To support Cell-to-Pack (CTP), new thermally… Read more »

Thermal conductive adhesives for next-generation cell-to-pack configurations (Webinar)

Cell-to-Pack is the direct bonding of individual battery cells to the battery pack’s cooling plate, and it’s a new trend in the EV market. It improves performance by providing higher pack energy density, improved part complexity, lower thermal loads on the battery pack, and simpler, lower-cost manufacturing of packs. To support Cell-to-Pack (CTP), new thermally… Read more »

Gap fillers for thermal management in electric vehicles

Sponsored by Parker Lord The article will be valuable for Electric Vehicle (EV) battery manufacturers as well as battery module and pack designers to help choose the right thermal interface material for battery pack needs. Two-component (2K) gap fillers provide customers with a variety of thermal conductivities and chemistries to choose from, which provide high… Read more »

Thermally conductive adhesives for next generation cell-to-pack configurations

Sponsored by Parker Lord With the significant growth and development of battery pack technologies, manufacturers of Electric Vehicles (EVs) are placing an increased emphasis on pack design optimization. Manufacturers seek lighter weight, yet more compact solutions to gain additional energy density and reduce cost. In parallel, they also strive for simpler and more affordable manufacturing… Read more »

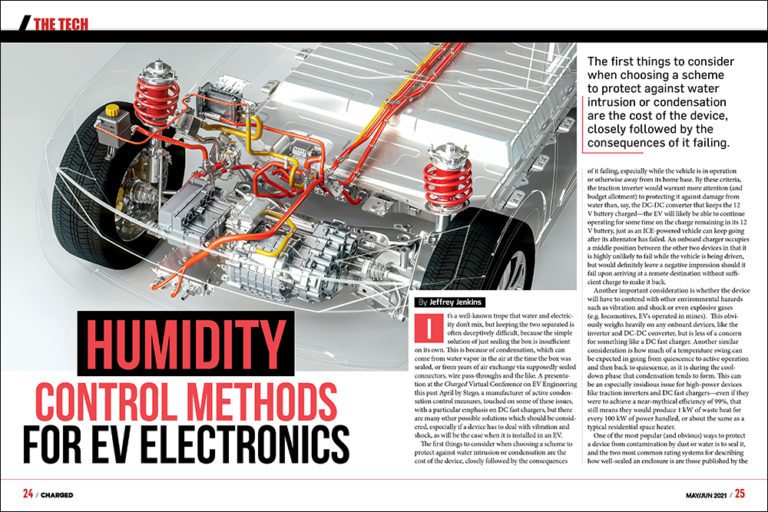

A closer look at humidity control methods for EV electronics

It’s a well-known trope that water and electricity don’t mix, but keeping the two separated is often deceptively difficult, because the simple solution of just sealing the box is insufficient on its own. This is because of condensation, which can come from water vapor in the air at the time the box was sealed, or… Read more »