In an update to its 2020 study, the Faraday Institution examines the UK EV market and forecasts future demand for battery production. The new report, “UK Electric Vehicle and Battery Production Potential to 2040,” predicts that by 2030, the UK will need around 100 GWh of annual supply to satisfy the demand for batteries for… Read more »

Search Results Found For: "sodium batteries"

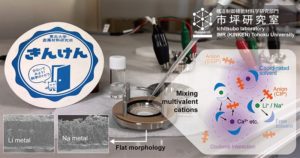

Researchers find additive can limit dendrite growth

A research team led by Dr. Hongyi Li and Dr. Tetsu Ichitsubo, both of Tohoku University in Japan, found that a multivalent cation additive can limit dendrite growth in rechargeable batteries by modifying the solvation structures of lithium or sodium ions in electrolyte. In an article published in Cell Reports Physical Science, the researchers say:… Read more »

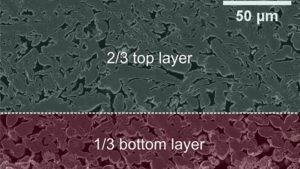

KIT researchers’ two-layer electrodes are simultaneously coated and dried

Researchers at the Karlsruhe Institute of Technology (KIT) have developed and tested a new concept for simultaneous coating and drying of two-layered electrodes. Drying times can be reduced to less than 20 seconds—one half to one third of the usual production time—without capacity losses. The institute continues to focus its research on coating and subsequent… Read more »

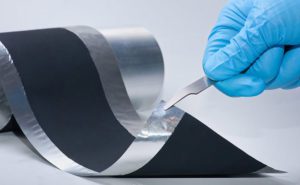

Fraunhofer Institute’s new dry-coating process reduces environmental impact

Researchers at the Fraunhofer Institute have developed a new dry-coating process that’s designed to reduce the environmental impact of electrode manufacturing. The Institute says its new DRYtraec process uses machines that do not require long drying tracks, and will take up less space than conventional battery electrode manufacturing systems. The new coating process uses similar… Read more »

Faraday Battery Challenge to fund 17 new tech projects

The Faraday Battery Challenge, a project initiated by the UK government to promote advanced battery technologies, has announced a new £10-million round of funding, which will be shared across 17 projects being undertaken by businesses and research institutions across the UK. The funded projects cover a wide range of topics, including a new sodium nickel… Read more »

Tesla develops new cost-slashing lithium extraction process

During last year’s Battery Day presentation, Tesla unveiled a number of new technologies, processes and plans, some of them only sketchily explained. One of these was a new lithium extraction process that Senior VP of Engineering Drew Baglino predicted could deliver as much as a 33% reduction in lithium costs. “What is the best way… Read more »

Battery makers Faradion and AMTE Power announce licensing deal

Battery manufacturers AMTE Power and Faradion have announced a collaboration that combines Faradion’s IP with AMTE’s design and manufacturing capabilities. The collaboration grants AMTE a license to manufacture and sell sodium-ion cells for battery packs. Faradion says its technology is scalable and can leverage AMTE’s existing lithium-ion manufacturing facilities. AMTE CEO Kevin Brundish said, “This… Read more »

First Cobalt performs feasibility study for Canadian cobalt refinery expansion

First Cobalt has announced positive results from an independent feasibility study conducted on its permitted cobalt refinery in Ontario, Canada. The study contemplates expanding the existing facility and adapting it to be North America’s first producer of cobalt sulfate, an essential component in the manufacturing of EV batteries. Study highlights: Annual production of 25,000 tons… Read more »

Carnegie Mellon researchers develop semi-liquid lithium metal anode to pair with solid ceramic electrolytes

Researchers from Carnegie Mellon University have developed a semi-liquid lithium metal-based anode that could lead to higher capacity and better safety than typical lithium metal-based batteries that use lithium foil as anodes. The research team published their findings in the June 2019 issue of Joule. “Incorporating a mewtallic lithium anode into lithium-ion batteries has the… Read more »

Fraunhofer’s dry coating process for electrodes could make cell production in Europe economical

Researchers at Germany’s Fraunhofer Institute for Material and Beam Technology IWS have developed a new battery cell production process that coats electrodes with a dry film instead of liquid chemicals. This simplified process saves energy and eliminates toxic solvents. The Fraunhofer researchers, with colleagues from Samsung, describe their findings in a new paper, “Overcoming binder… Read more »