Leak detection systems provider INFICON has highlighted the urgent need for comprehensive testing of all EV battery cells, modules and packs. North American EV battery manufacturers currently do not test 100% of individual cells assembled into battery packs for electrolyte leakage, leading to missed defects and possible battery fires, higher warranty costs and potential reputational… Read more »

Search Results Found For: "INFICON"

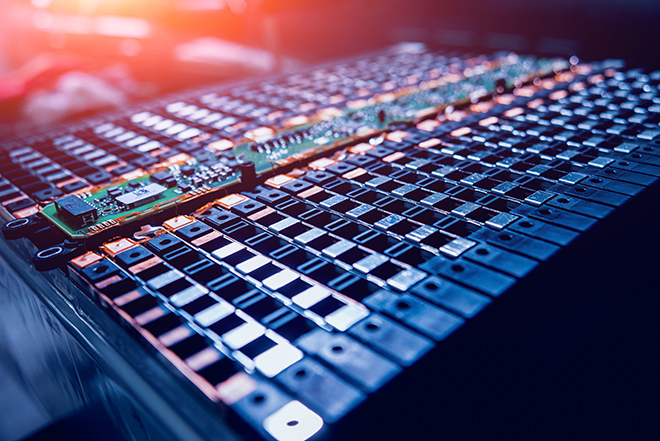

INFICON’s ELT Vmax enables individual leak testing for mass-produced EV battery cells

INFICON, a manufacturer of leak testing solutions, introduces the ELT Vmax—a leak detector specifically designed for integration into leak testing systems for the industrial high-speed mass production of lithium-ion and sodium-ion battery cells. The ELT Vmax tests the leak tightness of all battery cells filled with liquid electrolyte—lithium-ion or sodium-ion—in all formats, including prismatic, round… Read more »

INFICON releases ELT3000 PLUS electrolyte leak detector for Li-ion and sodium-ion batteries

INFICON, a leak-testing device and instrument manufacturer, has released an upgraded electrolyte leak detector for in-line leak testing of batteries. The ELT3000 PLUS directly detects electrolyte solvent leakage into a vacuum chamber to test ready-filled lithium-ion and sodium-ion batteries in all cell formats. It has manual and automatic in-line leak detection modes for fast cycle… Read more »

INFICON predicts huge growth in robotic leak testing at auto plants

INFICON, a supplier of leak-detection equipment, predicts that the percentage of global automotive plants with robotic leak-detection systems will jump from 5 percent today to 20 percent or more by 2024. The company attributes the rise to growing interest in EVs and autonomous vehicles. Robotic leak-detection techniques are either static and dynamic. In static detection,… Read more »

How To Increase Production Speed And Quality With Lithium-Ion Battery Leak Testing

Lithium-ion batteries are used in modern electric or fuel cell driven vehicles. Battery manufacturing is currently in transition from small scale, pilot line production to larger scale production. Production of high quality battery cells is mandatory to avoid large recalls but also to keep the production cost under control. In this session, we will explore… Read more »

Setting up your EV battery test lab for success

For electric vehicle (EV) manufacturers, suppliers and test facilities, intensive testing of EV batteries is crucial to secure an advantage over the competition. Efficient and reliable testing is essential for faster developments and shorter time-to-market. However, before testing can begin, thorough test lab planning is required. There are various approaches to planning and setting up… Read more »

Setting a new standard for battery leak testing

Defective cells can shorten battery life, decrease range, and lead to safety issues. A leaky cell housing, one common failure mode for Li-ion batteries, can allow ambient humidity to come in contact with the electrolyte, triggering an exothermic (heat-releasing) chemical reaction. Currently, the common practice in the battery manufacturing industry is to test cell packaging… Read more »

Advancing Leak Testing Of Rigid And Pouch Battery Cells By Electrolyte Detection

Download the slides (PDF) from this presentation here. Presented by: Sandra Seitz, Market Manager Automotive, INFICON Yessica Brachthäuser, Application Engineer, INFICON