Wildcat Discovery, a battery research company based in San Diego, has been granted a patent for the use of sulfolane-based electrolytes designed to improve the performance of Li-ion batteries containing silicon anodes. In 2013, the company was awarded a grant by the DOE’s Office of Energy Efficiency and Renewable Energy to develop new non-carbonate-based electrolytes… Read more »

Search Results Found For: "silicon anode"

Nexeon and partners win £7 million in funding to develop silicon anode tech

Silicon anode specialist Nexeon, along with a couple of partners, has been awarded £7 million in Innovate UK funding for the SUNRISE project, which will develop battery materials based on silicon as a replacement for carbon in the cell anode Nexeon will lead the silicon material development and scale-up stages of the project, while polymer… Read more »

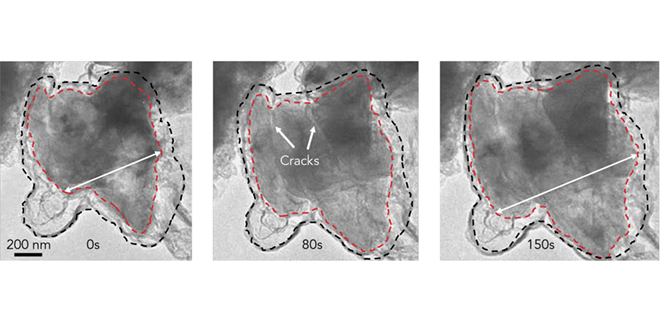

US Army partners with Brown University to study SEI on silicon anodes

The US Army Research Laboratory (ARL) and Brown University researchers have teamed up to study the solid electrolyte interphase (SEI) layer that forms on the anodes of lithium-ion batteries, with particular emphasis on experimental silicon anodes. The Army is working to replace its alkaline and nickel-metal hydride field batteries with Li-ion batteries. “The Army is… Read more »

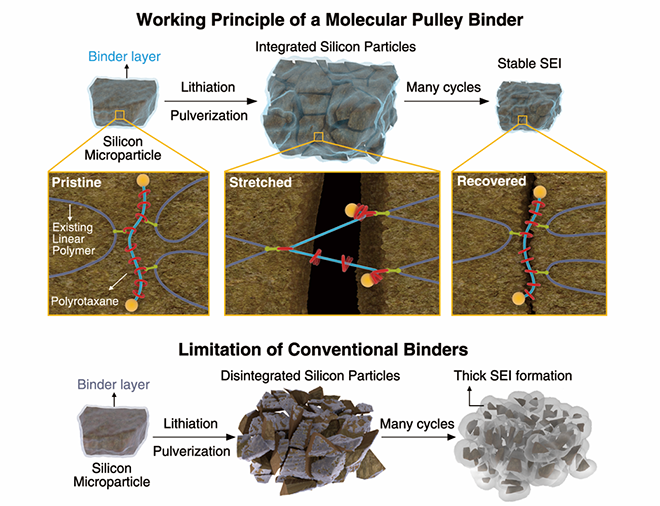

Molecular pulley leads to silicon anode breakthrough

Silicon anodes are receiving a great deal of attention, as they can enable batteries to deliver 3-5 times higher capacities compared with current graphite anodes. Although silicon is abundant and cheap, Si anodes have a limited number of charge-discharge cycles – typically less than 100 times. Their volume expands enormously during each cycle, leading to… Read more »

Researchers make a major advance in silicon anodes

Current electrode materials such as graphite are able to stably adsorb only a limited number of lithium ions, an inconvenient truth that restricts capacity. That’s why researchers around the world are investigating semiconductor materials such as silicon as alternative electrodes. Bulk silicon is able to accommodate enormous quantities of lithium, but the migration of the… Read more »

Graphene cages could be the key to silicon anodes

Battery boffins are buzzing about silicon anodes, which could store up to 10 times more energy than today’s anodes. The catch is that silicon particles tend to swell and crack during cycling, and to react with the electrolyte in unwanted ways. Now a team from Stanford University and the Department of Energy’s SLAC National Accelerator… Read more »

Paraclete Energy finds a way to make silicon anodes with good cycling performance

Silicon’s high theoretical charge capacity has inspired a tremendous amount of research into the possibility of using it to replace at least part of the graphite in lithium-ion battery anodes. However, Si presents major technical challenges. It can undergo a volume change of up to 300% during charging and discharging, limiting cycle life. Michigan-based Paraclete… Read more »

Tesla tweaks its battery chemistry: a closer look at silicon anode development

In mid-July, Tesla Motors made a trio of Model S update announcements. The new options included a 70 kWh rear-wheel-drive base model, an upgrade for the high-end battery pack from 85 to 90 kWh (providing about a 6% increase in range), and Ludicrous mode, which offers a 10% improvement in the car’s 0 to 60… Read more »

ProLogium and FEV Group showcase silicon composite anode for EVs

Lithium ceramic battery (LCB) developer ProLogium Technology has introduced a new silicon composite anode battery, which Germany’s FEV Group is using to develop a next-generation battery pack. According to the companies, the new battery system can reduce vehicle weight, increase energy efficiency, and improve charging speed. The system offers energy density of 749 Wh/L, and… Read more »

C-BATT commercializing silicon-carbon composite battery anode material

C-BATT, a joint venture between US lithium-ion battery components producer X-BATT and carbon and graphite products manufacturer CONSOL Innovations—a wholly owned subsidiary of US-headquartered CONSOL Energy—has launched the next phase of development and commercialization of Obsidia, its tunable silicon-carbon composite battery anode material made with domestically sourced carbon. The aim is to improve the energy… Read more »