The Implementation of Laser Drying Processes for Economical & Ecological Lithium Ion Battery Production (IDEEL) research project in Germany developed a laser-assisted roll-to-roll (R2R) drying process that could reduce the cost of lithium-ion battery manufacturing, according to German research organization Fraunhofer FFB. The hybrid process combines conventional, oven-based convection drying with laser drying based on… Read more »

Search Results Found For: "fraunhofer"

PEM develops laser drying process for battery production

The Chair of Production Engineering of E-Mobility Components (PEM) at RWTH Aachen University in Germany has completed a project to develop a laser-based drying process for battery production. The project, “Implementation of Laser Drying Processes for Economical & Ecological Lithium-Ion Battery Production” (IDEEL) involved PEM as well as the Fraunhofer Research Institution for Battery Cell… Read more »

CustomCells joins project to advance large-format round battery cells

German battery manufacturer CustomCells is participating in an €8-million research project to develop next-generation round battery cells. The Center for Solar Energy and Hydrogen Research Baden-Württemberg (ZSW), the Fraunhofer Institute for Manufacturing Engineering and Automation (Fraunhofer IPA) and the Karlsruhe Institute of Technology (KIT) are the scientific partners. CustomCells has chosen to locate its pilot… Read more »

Eleven companies join project to demonstrate optimized battery production for EVs

Eleven companies will jointly present their battery cell production project, demonstrating a model production process to scale and optimize robot-assisted production of EV battery cells and packs. Bosch Rexroth, DBR77, EDAG, FANUC, Fraunhofer FFB, IBG, KEYENCE, Lenze, Mybotshop, SCHUNK and Vision Lasertechnik will show how different technologies interact to make production processes scalable and increase… Read more »

Battery production systems made in Europe

Sponsored by Schuler. After acquiring the Italian Sovema Group, Schuler is gradually establishing itself as a system supplier in the field of battery production. The first successful large-scale projects show that the strategy is working. Schuler passed an important milestone as a supplier for gigafactories with the construction of a formation line for a large… Read more »

H2020 SOLiDIFY consortium produces prototype solid-state lithium battery

The H2020 SOLiDIFY consortium, coordinated by Belgian research organization Imec, has developed a lithium-metal solid-state battery with high energy density. The prototype battery pouch cell, manufactured by Imec in the assembly lab at EnergyVille, Belgium, has a “liquid-to-solid” processed solid electrolyte, which was jointly developed by Imec and its 13 consortium partners. The cell has… Read more »

COOLBat project develops lightweight EV battery enclosures

Researchers from Germany’s Fraunhofer Institute for Machine Tools and Forming Technology IWU have teamed up with partners in the COOLBat joint research project to develop next-generation battery enclosures for EVs. The COOLBat project focuses on making lighter enclosures to reduce power consumption and increase driving range by combining individual systems, packing more functions into a… Read more »

Farasis Energy researches plastic battery housing for increased EV safety

Farasis Energy, a battery manufacturing company, Kautex Textron, a supplier of energy storage systems, and the Fraunhofer Institute for High-Speed Dynamics aim to make plastic-based battery housings safer by means of virtual design to increase the safety of EVs. Farasis, which develops and produces lithium-ion battery technology and pouch cells for electromobility, is developing a… Read more »

Customcells raises 60 million euros for development of electric aviation

German battery maker Customcells has closed a Series A financing round for 60 million euros with investors that include VC World Fund, Abacon Capital, Vsquared Ventures and Porsche. The company plans to use the funds to expand activities in the electrification of air traffic, intensify R&D and further internationalize operations. Customcells, a spin-off of research… Read more »

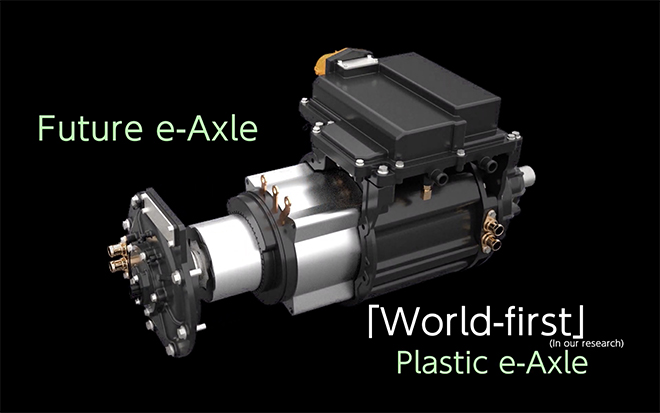

Sumitomo Bakelite to unveil eAxle demonstrator

After sharing some early technical findings at our Charged virtual conference, Sumitomo Bakelite has released additional information about its eAxle research project. Sumitomo is developing an 80 kg eAxle demonstrator that it expects to be finished in late Q1 of 2022. Based on the company’s plastics, the eAxle has stator encapsulation that replaces traditional paper… Read more »