German battery research facility Fraunhofer FFB and supply chain consulting firm Kerkhoff, part of Interpath, have formed a strategic alliance to support companies procuring battery cells to optimize costs. The companies are developing a cost modeling system designed to bring transparency to complex price structures. It helps industrial customers prepare for demanding supplier negotiations and… Read more »

Search Results Found For: "fraunhofer"

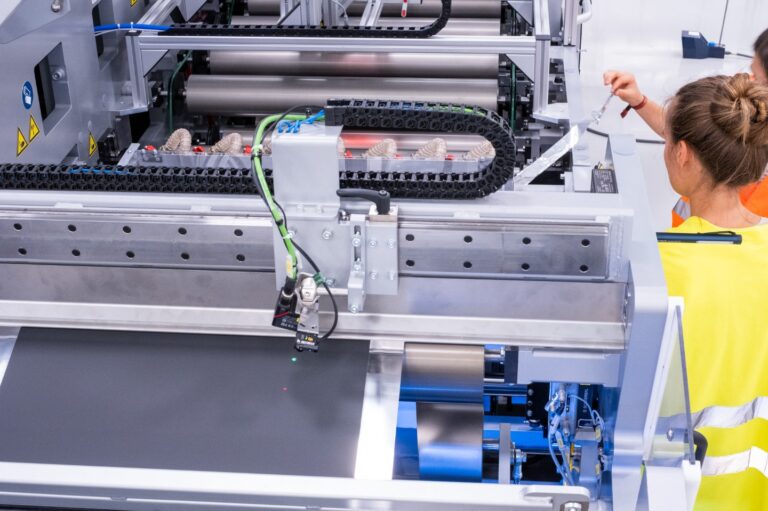

Fraunhofer starts construction of FFB Fab in Germany for battery cell production research

German battery technology research organization Fraunhofer FFB has started the second phase of construction of its large-scale research facility in Münster-Amelsbüren. The project will create production and research facilities covering an area of 20,000 square meters. Construction is scheduled to be completed by the end of 2027. The FFB Fab will expand the local plant… Read more »

Micromeritics and Fraunhofer ICT collaborate on electrochemistry training

Micromeritics Instrument, which supplies analytical instrumentation for the characterization of particles, powders and porous materials, is collaborating with the Fraunhofer Institute for Chemical Technology (ICT) on education and training for scientists and engineers. The partnership aims to accelerate the development of novel materials critical for clean technology applications, including thermochemical heat storage systems, electrolysis, fuel… Read more »

Hexagon and Fraunhofer develop electrochemical simulation software suite for battery design

Swedish industrial technology company Hexagon has developed a new battery cell design suite that combines its multi-physics material simulation and metrology software and Fraunhofer ITWM’s electrochemical simulation technology. Hexagon’s new battery design software integrates Fraunhofer ITWM’s Battery and Electrochemistry Simulation Tool (BEST) solver into Hexagon’s Digimat material behavior modeling software, which is part of its… Read more »

Micromeritics collaborates with Fraunhofer for battery cell production training

US-headquartered Micromeritics Instrument, a manufacturer of systems for measuring density, surface area and porosity, powder rheology, and catalyst activity, is partnering with German battery research institute and production facility Fraunhofer FFB, which is part of the Fraunhofer Battery Alliance. The collaboration focuses on educating future scientists and engineers and the production of training content for… Read more »

Fraunhofer IPK develops technical standards for EU digital battery passport

The Fraunhofer Institute for Production Systems and Design Technology IPK, a research institute in Berlin, is participating with the Battery Pass Consortium to design and implement the technical standards of the EU’s digital battery passport. The passport will be required by the EU Batteries Act for new traction batteries, two-wheeled-vehicle batteries and industrial batteries with… Read more »

Fraunhofer’s EKODA project aims to develop circular value creation

German research organization Fraunhofer has announced the launch of its EKODA project, which focuses on the mobility industry with the aim of addressing issues such as resource scarcity, rising prices of raw materials and energy, supply chain disruptions, and waste disposal. Its goal is to swap conventional recycling for what it calls a circular economy…. Read more »

Fraunhofer ILT and 6K Additive partner to create a life-cycle assessment for additive manufacturing

The Fraunhofer Institute for Laser Technology (ILT) and 6K Additive, the developer of a proprietary microwave plasma production system, have partnered to create a complete life-cycle assessment (LCA) for additive manufacturing. The study will use 6K Additive’s Ni718 powder for an industrial component manufactured on Fraunhofer ILT’s laser powder bed fusion machine (LPBF) to better… Read more »

Fraunhofer Institute’s new dry-coating process reduces environmental impact

Researchers at the Fraunhofer Institute have developed a new dry-coating process that’s designed to reduce the environmental impact of electrode manufacturing. The Institute says its new DRYtraec process uses machines that do not require long drying tracks, and will take up less space than conventional battery electrode manufacturing systems. The new coating process uses similar… Read more »

AKASOL partners with Fraunhofer to develop automated battery recycling

German battery manufacturer AKASOL is has partnered with the Fraunhofer Research Institution to develop automated recycling processes for battery packs. “The rising demand for high-performance battery systems means that more raw materials, such as lithium, cobalt or nickel, are needed to manufacture these energy-storage technologies,” explains AKASOL Head of Product Management Dr. Björn Eberleh. “In… Read more »