Aptera is different. While other EV-makers aspire to become “the next Tesla” by building high-performance vehicles that look just like the ICE vehicles drivers are used to, Aptera is focusing on building the most efficient and greenest vehicles possible. Critics may say that consumers won’t buy an unusual three-wheeled aerodynamic vehicle (Aptera might dispute that—it… Read more »

Search Results Found For: "motiv power"

Today’s EV engineering webinar schedule: Wednesday, October 19th

Charged is hosting a virtual conference on EV engineering that’s free to attend and it starts today. The conference includes live webinar sessions with interactive Q&As and on-demand webinars. View the daily session schedule online here. All of the live sessions will be recorded and available to view after the broadcasts. You can access the… Read more »

Exploring The Latest Rimac Battery Platform

This session will include discussions with Dr Wasim Sarwar, Head of Research & Advanced Engineering at Rimac Technology, covering: – Exploring Rimac’s latest battery platform, its capabilities and the technologies involved – Sharing key developments on the deployment of software as well as the new methods and techniques employed to maximise results – Delving deeper… Read more »

Virtual Twin For Battery Engineering

With the rise of Battery Powered Electric Vehicle, our world is becoming more and more dependent on batteries especially in Transportation & Mobility and High Tech industries. These disruptive changes are driven by regulations and consumers demands (Range, cost, sustainability, etc.). The complete value chain from material suppliers to Battery makers to Automotive/High Tech OEMs… Read more »

EV Lubes: The Latest In Driveline E-Fluid Technology

New driveline e-fluids, designed to enable the latest electrified powertrains to perform at their very best, are entering the market. Many earlier electric vehicle powertrains were developed using automatic transmission fluids (ATF). Not optimised for EVs, increasingly these are being superseded by the latest generation of lubricant fluid technology, termed driveline “e-fluids”. e-Fluids are optimised… Read more »

Innovative New Anode-Free Cell Enables Dual-Chemistry EV Battery Architectures

Michigan-based energy storage company Our Next Energy (ONE) has unveiled a 240 Ah prismatic anode-free cell after a 12-month R&D effort. ONE new technology will enable the commercialization of its Gemini dual-chemistry architecture, which will be integrated into a BMW iX prototype vehicle later this year. ONE’s 1,007 Wh/L cell eliminates the need for graphite… Read more »

New Innovative Laser Welding For Hermetic Seal Of Aluminum Alloys In EV

Aluminum alloys are commonly used materials for EV power electronics housing and cold plate. To achieve maximum packaged protection from environmental elements that could reduce reliability or cause leaking, hermetic seals on Aluminum alloys are often required. This presentation will introduce TRUMPF latest innovation on using a combination of BrightLine Weld Beam Shaping technology and… Read more »

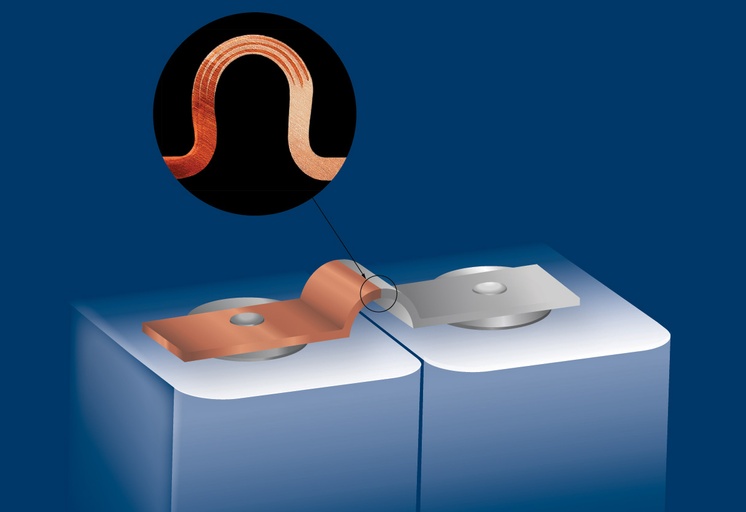

Innovative clad metal solutions for next-generation batteries (Webinar)

The production of electric and hybrid vehicles demands advanced materials that solve even the most difficult design challenges and perform reliably under harsh automotive conditions. In this free webinar at our Fall Virtual Conference (October 17-20, 2022), presented by Materion, we will discuss how the latest clad metal technologies enable safer and more reliable lithium-ion… Read more »

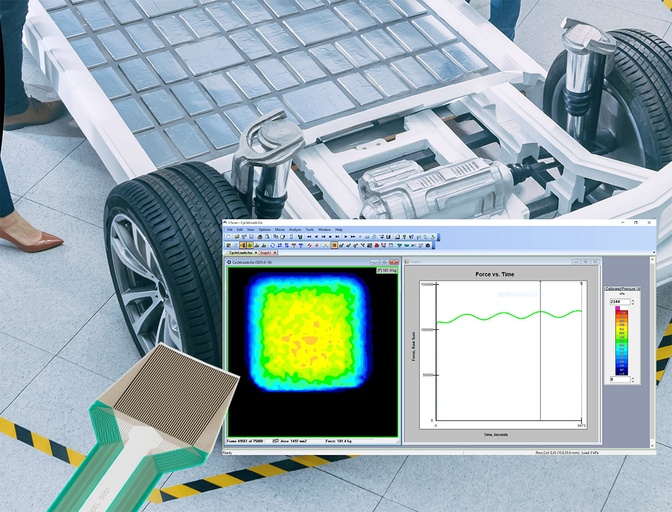

How to improve EV battery design with pressure mappings (Webinar)

Engineers involved in battery and EV design and manufacturing have common goals: to maximize performance, lifespan, and safety. Join this session at our Fall Virtual Conference on EV Engineering, presented by Tekscan, to learn why pressure mapping is a critical step in battery R&D for improving battery life, and how to apply it in quality… Read more »

Keysight and Jiyun collaborate on EV battery test system

Keysight Technologies, a test and measurement technology company, is collaborating with the Chinese EV tech company Jiyun Technologies on a battery test system for EVs. The battery test system features Keysight components, including its RPS7900-series regenerative power supply, DAQ973A Data Acquisition System and CAN bus communication interfaces. According to Keysight, the system’s regenerative power enables… Read more »