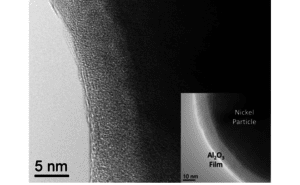

Argonne National Laboratory has granted an exclusive license to Colorado-based nano-coating specialist Forge Nano to commercialize Argonne’s patented system for continuous atomic layer deposition. Atomic layer deposition (ALD) is a process that deposits a uniform, ultrathin encapsulating coating around any material. It can be used to upgrade materials such as powders utilized in lithium-ion batteries,… Read more »

Search Results Found For: "NANO ONE"

Converting bulk alloys to oxide nanowires could produce cheaper battery membranes

Image: Alloy in solvent A simple technique for producing oxide nanowires directly from bulk materials could dramatically lower the cost of producing the one-dimensional (1D) nanostructures. That could enable the production of thermally stable, strong battery membranes able to withstand temperatures of more than 1,000° C. In “Transformation of bulk alloys to oxide nanowires,” recently published… Read more »

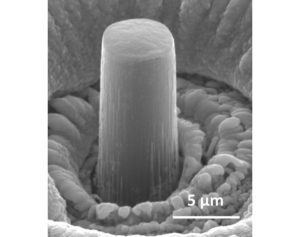

Nanoscale measurement of lithium metal could lead to suppressing dendrite formation

Lithium metal, which can store more energy than carbon, would seem to be an ideal anode material, except for one serious flaw: dendrites, tiny needle-like branching structures that can grow through the battery, eventually causing a short circuit. Now, a joint team of researchers from Caltech and Carnegie Mellon University has measured the strength of… Read more »

$20 million in Series A funding for Forge Nano’s precision nano-coatings

Forge Nano, formerly PneumatiCoat Technologies, is a Colorado-based startup that has developed a technology to enable precision nano-coatings at scale for manufacturing of Li-ion battery materials. The company recently closed a Series A investment of $20 million to expand its manufacturing capacity and fuel its growth. A nano-coating is an ultra-thin layer that improves how… Read more »

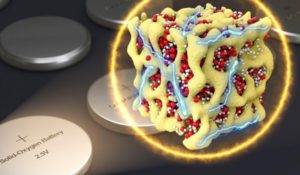

Researchers use nanolithia to improve efficiency and longevity of lithium-air batteries

Lithium-air, or lithium-oxygen, has been touted as the ultimate battery technology, because its theoretical energy density is ten times that of current lithium-ion solutions. However, scientists have struggled to overcome major challenges with the technology. The batteries waste a lot of energy as heat, degrade relatively quickly, and often require extra components to pump oxygen… Read more »

Paraclete Energy says its low-cost silicon nanoparticles can at least double your current anode capacity

Silicon has a theoretical charge capacity ten times higher than typical graphite. That is why a mind-blowing number of researchers are working towards replacing more and more of the graphite used in today’s lithium-ion battery anodes with silicon. In the last issue of Charged, we discussed Tesla’s announcement that it had begun to use small… Read more »

Kevlar-based nanocomposite foils dendrites for bulletproof batteries

Those doggone dendrites are a bane of battery builders. These pesky fern-like growths can form on the surfaces of anodes during cycling, reducing battery life or even causing a catastrophic short circuit – this is how the battery fires on the Boeing 787 are thought to have started. A team of researchers from the University… Read more »

Silicon nanowire batterymaker Amprius raises $30 million in Series C funding

Amprius, a developer of lithium-ion batteries using silicon anodes, has raised $30 million in a Series C funding round, which it will use to commercialize its batteries and further develop the next generation. The company introduced its first generation of batteries in May 2013, and is supplying smartphone and tablet OEMs with its first two… Read more »

Bob Lutz joins the board of NanoSteel

NanoSteel, a privately held company that makes proprietary nano-structured steel materials, announced this week that automotive visionary Bob Lutz has been appointed to the company’s Board of Directors. Through the development of patented alloys, NanoSteel has created a new class of steel that allows automotive engineers and designers to reduce weight through the use of… Read more »

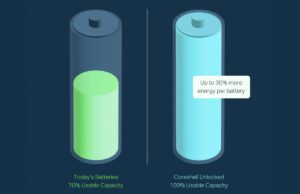

Ferroglobe and Coreshell to produce battery-grade metallurgical silicon for EVs

Ferroglobe, a producer of silicon metal and ferroalloys, and Coreshell, a US-based battery technology company, have signed a memorandum of understanding under which they plan to produce battery-ready metallurgical silicon for the development of low-cost, high-range EV batteries. Automakers are keen to use more silicon in anodes, because it can potentially store up to 10… Read more »