The DOE’s Loan Programs Office (LPO) closed a $102.1-million loan to Syrah Technologies to increase the production capacity of an active anode material processing facility. The Syrah Vidalia facility in Louisiana produces graphite-based active anode material. According to the DOE, the facility is “the only vertically integrated, large-scale AAM manufacturer outside of China and the… Read more »

Search Results Found For: "graphite"

Pilot project upcycles graphene oxide from end-of-life EV batteries

Graphmatech has announced that a pilot project with Graphenea and Northvolt has upcycled graphene oxide from end-of-life EV batteries. “Producing graphene oxide from end-of-life batteries makes the entire graphene value chain more sustainable and cost-effective,” says Graphenea Advanced Materials CEO Jesus de la Fuente. “This breakthrough uses the material left after Northvolt has extracted valuable… Read more »

The EV raw materials crunch: How bad, how long, how to solve it?

This article originally appeared in Issue 60: April-June 2022 Subscribe now Every new technology must overcome a series of temporary constraints on its way to widespread adoption. Since modern EVs appeared a decade ago, they’ve motored past many of these bottlenecks, (or hurdles, or roadblocks—pick your preferred metaphor). Range has increased, access to charging infrastructure has expanded,… Read more »

A closer look at brushed AC motors in EVs

Everything old is new again: BMW’s fifth-generation eDrive features a wound-field synchronous AC motor Brushed DC (and AC/DC universal) motors are much maligned for a number of reasons, but one of the chief—if, perhaps, somewhat exaggerated—complaints is that the graphite brushes, and the segmented copper commutator they ride on, wear out over time, all the while producing… Read more »

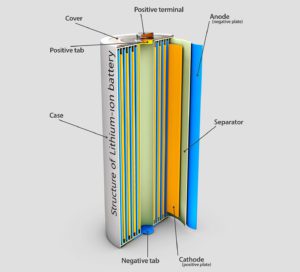

ONE’s hybrid battery pack combines the best aspects of two chemistries to deliver 600 miles of EV range

Q&A with ONE CTO Dr. Steven Kaye. There is a wide range of characteristics that describe the performance of any given battery chemistry: energy density, specific energy, specific power, discharge efficiency, self-discharge rate, cycle life, calendar life, and—not the least important—cost. Some types of Li-ion chemistries are really good in a few characteristics but fall… Read more »

Mitsubishi Chemical Holdings expands its anode materials business

Mitsubishi Chemical Holdings Group (MCHG) plans to increase its production capacity of natural graphite anode materials in China from 2,000 tons to 12,000 tons per year. MCHG’s Chinese subsidiary Qingdao Lingda Kasei produces spherical graphite for the anode materials, which another Chinese subsidiary, Qingdao Anode Kasei, then uses to produce anode materials for lithium-ion batteries…. Read more »

BMW to open facility for demonstrating and analyzing Li-ion cell production

BMW plans to open a Cell Manufacturing Competence Centre (CCMC) in the fall of 2022 to demonstrate and study lithium-ion cell production. Located in Parsdorf, Germany, the CCMC will develop a pilot line for battery cell production in stages. At the beginning, systems for electrode production will be installed and run, graphite and nickel oxides… Read more »

Sila’s Washington anode material plant to begin production in 2024

Battery materials maker Sila Nanotechnologies will open an anode material plant in Moses Lake, Washington. The company claims its anode material boosts the energy density of lithium-ion batteries by 20%. The 600,000-square-foot hydro-powered facility will begin producing silicon-based anode material in the second half of 2024, and full production is scheduled for the first half… Read more »

Defense Production Act could boost domestic production of critical battery minerals

Shortages of battery materials represent a serious bottleneck that’s sabotaging environmental goals and costing consumers a bundle, and the supply crunch seems likely to be with us for some time. President Joe Biden has invoked the Defense Production Act in order to encourage domestic production of critical raw materials. Doing so added critical battery minerals… Read more »

Mercedes outlines battery recycling strategy, will open recycling plant in Germany in 2023

Mercedes-Benz has unveiled plans to expand its global battery recycling strategy. The automaker will build its own battery recycling plant in Kuppenheim, Germany, and plans to enlist partners for battery recycling in China and the US. “Mercedes-Benz is pursuing a maximum circular economy for all raw materials used,” said Board Member Jörg Burzer. “Sustainable battery… Read more »