Sponsored by 3D Systems. Lighter vehicles, faster product launches and supply chain resilience The design freedom inherent of additive manufacturing streamlines the production of complex designs. A variety of intricate patterns and shapes can be used with EV vehicles for body interior components, dashboard elements, battery housings, electronic board enclosures, heat exchangers, connectors, metal structural… Read more »

Sponsored Content

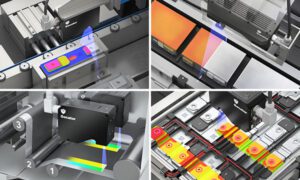

3D smart sensors for inline EV battery inspection

Sponsored by LMI. The increase in demand for EV Batteries has already permanently transformed the car manufacturing landscape, with almost all major automotive companies now operating electric vehicle production lines. While electric vehicles do have less moving parts than their internal combustion engine (ICE) counterparts, manufacturing them is still extremely complex. From stators and rotors,… Read more »

EV charger connectivity: The benefits of 4G cellular connectivity

Sponsored by Legrand. As the world shifts towards electric vehicles (EVs), investments in EV charger infrastructure must follow suit. Current research predicts that 54% of new car sales and 33% of the global fleet will be electric by 2040. With this rapid adoption of EVs on a global scale, there is an increasing demand for… Read more »

Bidirectional and regenerative EV test equipment: technical gains with environmental benefits

Sponsored by Chroma Systems Solutions. Reducing the carbon footprint and optimizing thermal cooling are paramount in modern manufacturing and have become significant criteria for selection and deployment of automated test equipment. In addition, budget constraints could be circumvented by the use of multi-purpose instrumentation. Last but not least, replenishing dissipated power to the grid will… Read more »

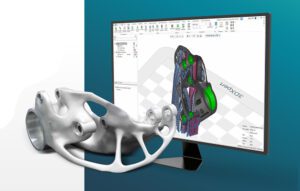

How to use generative engineering in EV architecture exploration

Sponsored by Siemens. Make informed design decisions early on by quantifying millions of architectures virtually Architecture analysis, whether it is a powertrain architecture or a cooling system architecture, ensures that the system architectures are aligned with desired requirements and that all the possibilities are thoroughly explored. It is an essential aspect of Model-Based Systems Engineering,… Read more »

How to power SiC or IGBT half bridges in EVs

Sponsored by Skyworks. When it comes to building power systems, the half bridge switch topology is king. But as they say, the devils in the details. In this whitepaper, we’ll dig into the challenges of designing high-performance half bridges for electric vehicles where it’s imperative to squeeze every drop of performance from a design. Specifically,… Read more »

Assessing technologies for dielectric protection of battery system components

Sponsored by Parker Lord. With the growth and development of battery pack technologies, manufacturers of electric vehicles (EV) place greater emphasis on pack design optimization, seeking more compact solutions to improve energy density and reduce cost. In the assembly of high-voltage battery packs, dielectric protection is critical. Manufacturers often apply dielectric materials to the battery… Read more »

NACS vs CCS: A comprehensive comparison to help you opt for the one that fits best

Sponsored by AMP. By Anil Paryani, CEO & CTO – AMPTesla has taken a huge leap in accelerating EV adoption and bringing the vision of clean energy closer, by announcing the opening of its EV connector design to the world. The announcement invites charging network operators and vehicle manufacturers to install the Tesla charging connector… Read more »

Enabling next-generation EV batteries with thermally conductive adhesives

Sponsored by Henkel. With the rapid growth and adoption of electric vehicles, OEMs and battery manufacturers are turning to technology to make EVs more efficient and affordable. Engineers, seeking ways to optimize the battery and its components for long range, safety, and reliability, are turning to the “Cell-to-Pack” configuration for next-generation battery designs. Most of… Read more »

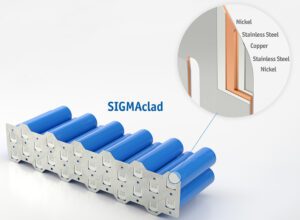

Li-ion battery pack connector plates with high thermal and electrical conductivity that are easily welded (Whitepaper)

Sponsored by Engineered Materials Solutions. Increasing demand for high power and high-capacity cells are major growth factors for the Li-Ion cylindrical battery market. As such, the demand for battery packs with higher energy output is also growing in sectors such as electric vehicles, industrial power tools, energy storage, consumer electronics, aerospace, defense, and others. These… Read more »