American Resources, through its holding in ReElement Technologies, which is developing rare earth element (REE) and critical mineral refining capacity, has agreed to enter a joint venture (JV) with Exigo Battery Solutions to use ReElement’s rare earth oxide refining technologies within the US and India to produce purified rare earth oxides. Exigo will initially source,… Read more »

Search Results Found For: "rare earth"

USA Rare Earth and PolarStar Magnetics partner to deliver US-made rare earth magnets

USA Rare Earth, which is building an integrated rare earth element magnet production supply chain, has signed a memorandum of understanding (MOU) with programmable magnet manufacturer PolarStar Magnetics to develop its prototype magnet capabilities. Using the available capacities at USA Rare Earth’s facilities, PolarStar will be included in early-round testing of US-produced magnets. Discussions will… Read more »

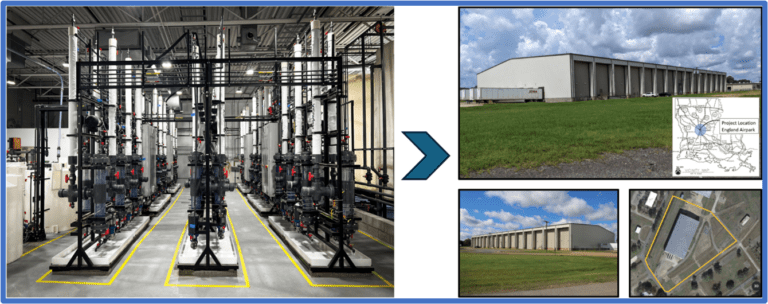

US Department of Defense increases funding for Ucore’s Louisiana rare earth processing plant

Ucore Rare Metals has reached a firm fixed price agreement for an $18.4-million increase to its current $4-million funding from the US Department of Defense to launch its RapidSX rare earth element separation technology toward full-scale operation. The funding through the US Army Contracting Command-Orlando will facilitate the construction of a production-ready commercial RapidSX machine… Read more »

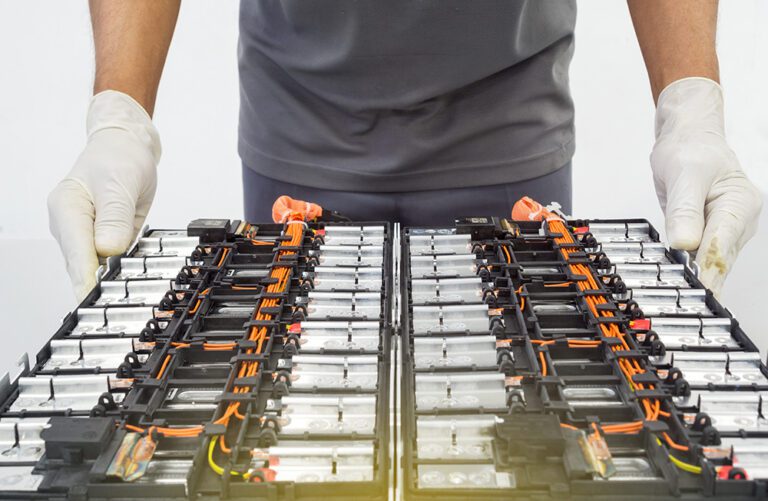

Electrified Materials receives EPA permit for recycling batteries and rare earth magnets

Electrified Materials, a subsidiary of American Resources, has received a Resource Conservation and Recovery Act (RCRA) permit issued by the Environmental Protection Agency (EPA) and the Indiana Department of Environmental Management (IDEM). Electrified Materials recycles end-of-life and non-spec lithium-ion batteries and rare earth magnet materials from products such as wind turbines, EV motors, consumer electronics… Read more »

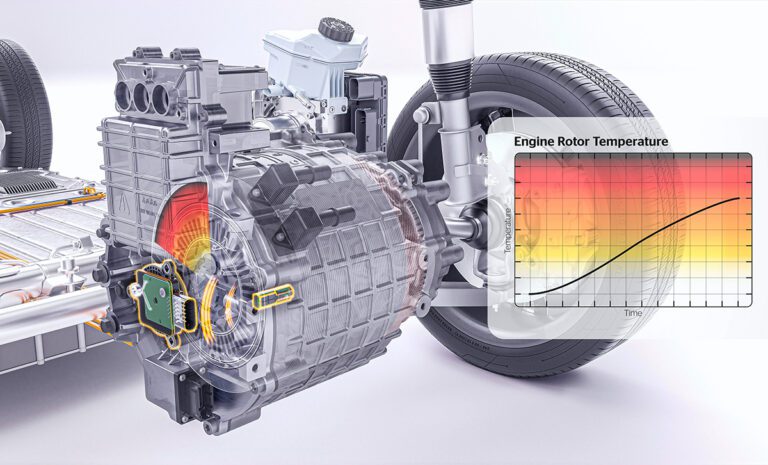

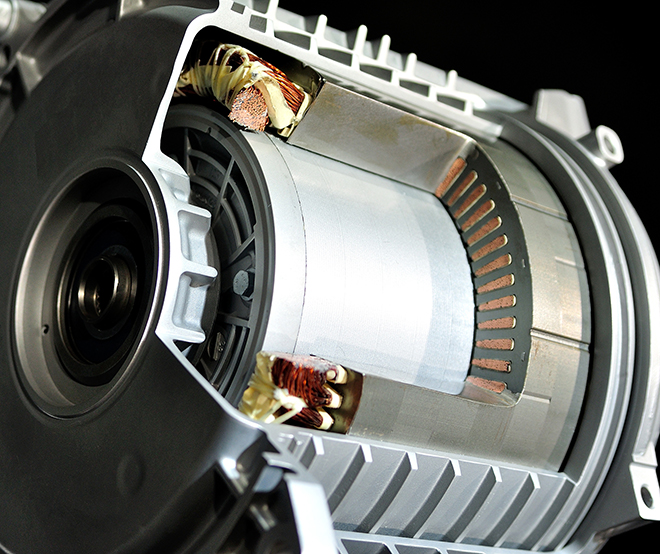

Continental’s new sensor measures heat in EV motors, reduces need for rare earths

Continental has developed a new sensor technology that measures the temperature inside permanently excited synchronous motors in EVs directly on the rotor. The company says its e-Motor Rotor Temperature Sensor (eRTS) delivers significantly more precise measurement results than the current software-based temperature simulation. This should enable vehicle manufacturers to reduce the amount of rare earth… Read more »

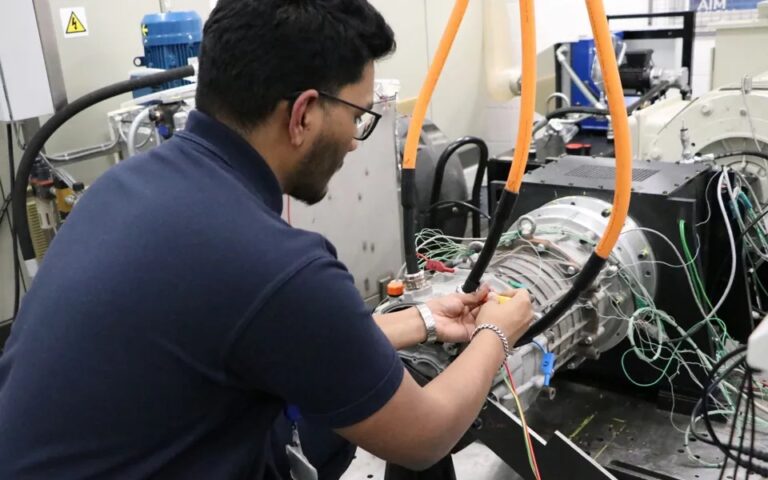

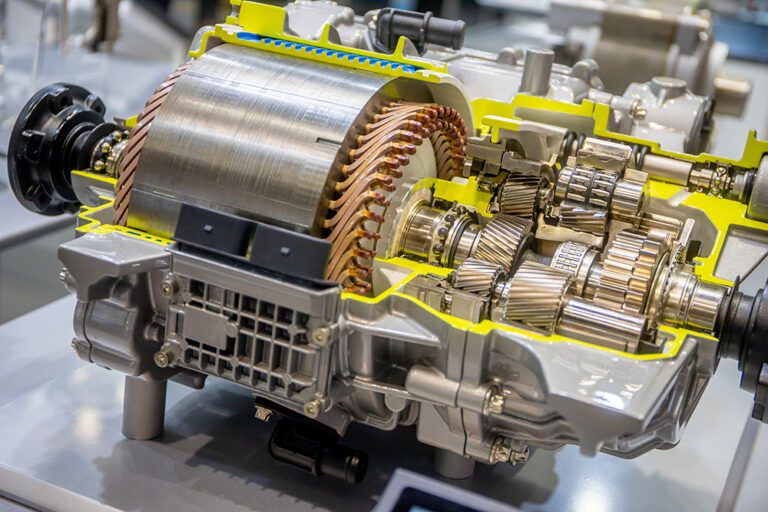

Ricardo develops electric propulsion motor with no rare earths or copper

Engineering consulting company Ricardo has designed, developed and tested a prototype electric propulsion module, Alumotor, a synchronous reluctance motor that does not contain critical raw materials such as rare earths or cobalt. Alumotor was delivered within Innovate UK’s funded consortium, led by Ricardo, which aims to address issues related to the environmental impact of materials… Read more »

Noveon Magnetics to supply rare earth magnets to Nidec Motor

Nidec Motor, a US-based manufacturer of commercial, industrial and appliance motors and controls, and Noveon Magnetics have signed a five-year, binding offtake agreement to potentially supply more than 1,000 tons of finished sintered neodymium iron boron (NdFeB) rare earth magnets. Deliveries are set to begin in 2025, supporting Nidec’s operations across industries including automation, industrial,… Read more »

MP Materials establishes rare earth magnet production in the US

MP Materials produces specialty materials that are vital inputs for the EV and renewable energy industries (see our feature article from March 2024). The company is expanding its manufacturing operations downstream to provide a full supply chain solution from raw materials to magnetic products. Now MP Materials says it has reached a pivotal milestone in… Read more »

Cyclic Materials and SYNETIQ partner to recycle rare earth elements from vehicle motors

Canada-headquartered metals recycler Cyclic Materials has signed a collaboration agreement with SYNETIQ, a UK-headquartered vehicle salvage and recycling company, for the recycling of end-of-life electric motors containing rare earth elements. The motors to be supplied by SYNETIQ include hybrid and EV drive motors, as well as auxiliary motors found in all vehicles. To help meet… Read more »

ReElement Technologies partners with EDP Renewables for rare earth magnet recycling

ReElement Technologies, a rare earth element and critical battery metal producer, has partnered with EDP Renewables North America, a renewable energy supplier, to recycle rare earth materials for wind turbines and EV motors. The partnership aims to develop a circular supply chain for renewable energy equipment and inputs by efficiently and sustainably recycling neodymium-based permanent… Read more »