German automaker Volkswagen is investing C$69 million ($48 million) to acquire a 9.9% stake in lithium exploration company Patriot Battery Metals and secure an offtake commitment for its battery manufacturer PowerCo to supply 100,000 tonnes of spodumene concentrate per year over a 10-year term and a potential 5-year extension period. Patriot will use the proceeds from… Read more »

Search Results Found For: "PowerCo"

NOVONIX signs offtake deal to supply battery materials to Volkswagen’s PowerCo

Battery materials and technology company NOVONIX has signed a binding offtake agreement with PowerCo for a minimum of 32,000 tonnes of synthetic graphite material over a five-year term starting in 2027. German automaker Volkswagen established PowerCo in 2022 to ramp up its global battery cell production. PowerCo oversees international factory operations, advances in cell technology… Read more »

VW’s PowerCo to help produce QuantumScape solid-state battery cells

Volkswagen’s battery company PowerCo SE and US solid-state lithium metal battery developer QuantumScape have agreed to industrialize QuantumScape’s technology. QuantumScape’s platform is based on its solid-state ceramic separator, which enables the use of a pure lithium metal anode. Once certain technical milestones and royalty payments have been reached, QuantumScape will grant PowerCo a non-exclusive license… Read more »

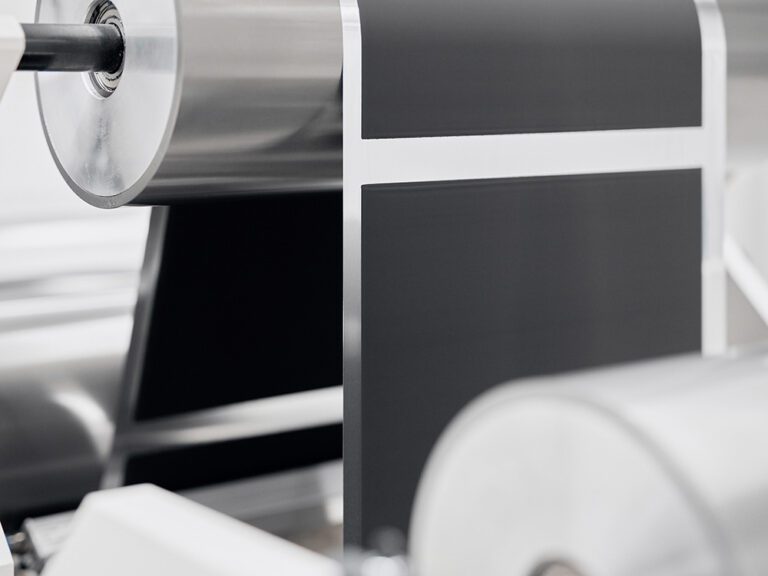

PowerCo says its new cell production procedure saves huge amounts of energy and floor space

Volkswagen Group-owned battery manufacturer PowerCo SE plans to introduce a new battery cell manufacturing method in its plants in Europe and North America. PowerCo predicts that its new Dry Coating procedure may save 30% of energy consumption and 15% of floor area, saving hundreds of millions of euros annually. According to a Joint Development Agreement,… Read more »

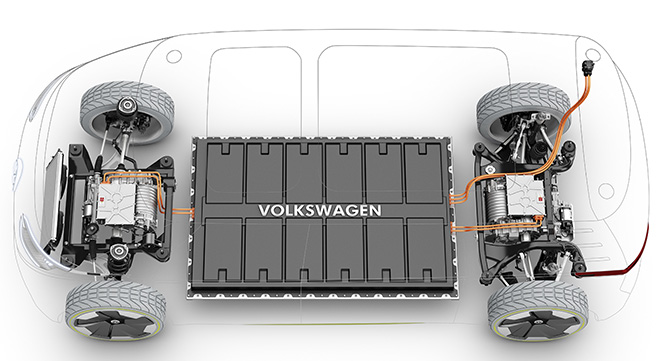

Volkswagen and Powerco SE to build their largest cell factory in Canada

The Volkswagen Group’s battery company PowerCO SE plans to build its largest gigafactory in St. Thomas, Ontario, Canada. This is the first cell factory in North America for VW. The company said its goal is to produce up to 90 gigawatt-hours of battery capacity per year. The planned investment is upwards of 4.8 billion euros…. Read more »

Volkswagen and PowerCo SE to search for a battery cell factory site in Canada

The Volkswagen Group and its recently founded battery company PowerCo SE intend to rapidly expand their global battery business to North America. To that end, Volkswagen and the Canadian government have signed a Memorandum of Understanding to identify suitable sites for a battery cell factory in Canada. The two parties will continue their cooperation in… Read more »

Novonix receives $755-million conditional DOE loan commitment for Tennessee graphite plant

Novonix, a battery materials and technology company, has received a conditional commitment from the US Department of Energy for a direct loan of up to $754.8 million for a proposed graphite facility in Chattanooga, Tennessee. If finalized, the financing from the DOE’s Loan Programs Office would be applied towards partially financing the construction of the… Read more »

A closer look at Li-ion dry electrode coating technology

The dry electrode coating process has the potential to enable the production of better, greener, more cost-effective batteries. It relies on advanced fluoropolymer binders with Teflon™ For a few years now, Charged has been reporting on how dry electrode coating processes have the potential to revolutionize battery production by eliminating the use of hazardous, environmentally… Read more »

How Umicore is ensuring sustainability in the North American EV battery chain

Q&A with Umicore’s Robert Privette Umicore traces its roots to a Belgian mining company formed in 1906. Since then, it has moved on from mining to a variety of high-tech pursuits including refining, recycling and the manufacture of specialized metal products. Today it’s one of Belgium’s largest companies, and has a strong presence in e-mobility,… Read more »

Study finds recovering materials instead of shredding improves battery recycling

Karlsruhe Institute of Technology (KIT) researchers and industry partners including PowerCo, Umicore, Weber Ultrasonics and Siemens are working together to improve spent battery recycling by recovering active components while maintaining functionality. The consumption of energy and chemicals in current recycling processes is high. The new approaches are based on the direct recycling of active materials… Read more »