Sponsored by Parker Lord With the significant growth and development of battery pack technologies, manufacturers of Electric Vehicles (EVs) are placing an increased emphasis on pack design optimization. Manufacturers seek lighter weight, yet more compact solutions to gain additional energy density and reduce cost. In parallel, they also strive for simpler and more affordable manufacturing… Read more »

Search Results Found For: ""Parker LORD""

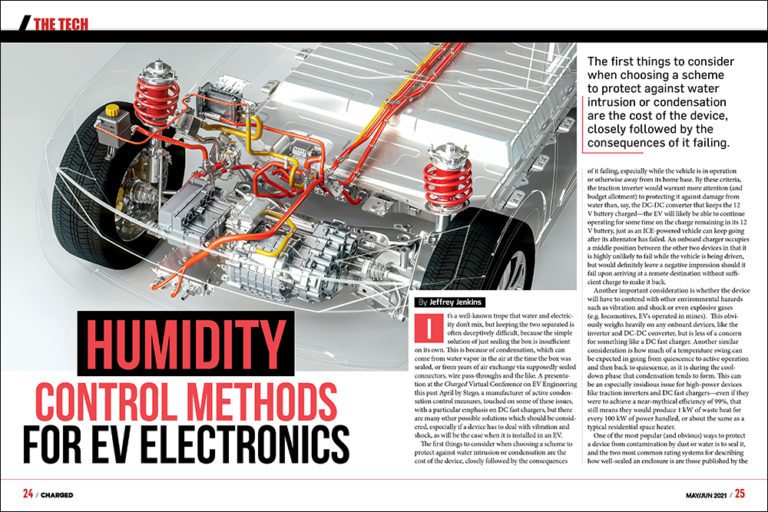

A closer look at humidity control methods for EV electronics

It’s a well-known trope that water and electricity don’t mix, but keeping the two separated is often deceptively difficult, because the simple solution of just sealing the box is insufficient on its own. This is because of condensation, which can come from water vapor in the air at the time the box was sealed, or… Read more »

Design Benefits Of Using Structural Adhesives To Assemble EV Battery Boxes

Traditional joining techniques in the automotive industry include welding and mechanical fasteners. However, many challenges arise when using these methods. By using structural adhesives, the need for mechanical fasteners as well as post-weld rework is eliminated. Adhesives also eliminate heat-affected zones and can double as a sealant. In traditional fastening methods, mounting lugs, screws, and… Read more »

Over 50 free EV engineering sessions confirmed: Charged Virtual Conference starts in two weeks

The Spring 2021 sessions list for the Charged Virtual Conference on EV Engineering is out now. Just like the content Charged brings you every day, conference topics will span the entire EV engineering supply chain and ecosystem including motor and power electronics design and manufacturing, cell development, battery systems, testing, powertrains, thermal management, circuit protection,… Read more »

Flame-Resistant Coatings For EV Battery Packs

When designing battery packs for electric vehicles, fire safety in the event of battery cell failures is a difficult challenge to solve. Join our session on fire-resistant coatings to learn how these products enable the use of lighter-weight substrates while maintaining fire-safety standards. What You’ll Learn:– Understand the capabilities and limitations of flame-resistant coatings– Learn… Read more »

3 factors that impact gap filler reworkability in EV battery packs

Sponsored by Parker LORD The design of electric vehicle battery packs may vary among manufacturers but commonly, the battery is attached to its cooling plate not only with fasteners but also thermally conductive polymeric materials called gap fillers. Gap fillers can outperform thermal pads in this application to achieve lower thermal impedance, as the gap… Read more »

Webinar: Rework ability of gap fillers in EV battery packs

The fast-growing electric vehicle market demands robust and efficient thermal management solutions for battery packs, such as gap fillers and thermal pads. Gap fillers outperform thermal pads to achieve lower thermal impedance, as the gap fillers conform to surface roughness before curing. This allows gap fillers to adhere well to surfaces and provide mechanical support… Read more »