Join this presentation at next week’s Virtual Conference on EV Engineering, presented by tesa tape, where we will discuss: Reserve your spot—it’s free! Other sessions at our Spring Virtual Conference include: Formulated Fluids: An Upgrade In Battery Immersion Cooling The world of global transportation is becoming increasingly electrified and with this comes new hardware and… Read more »

Search Results Found For: "Battery venting"

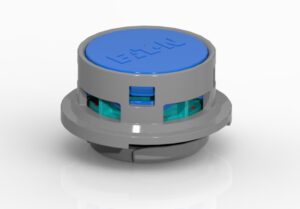

Eaton introduces 3-in-1 EV battery pack vent valve

Power management company Eaton has introduced a 3-in-1 battery pack vent valve for EV batteries. The valve is capable of three functions: battery case leak-checking, and both passive and active venting to provide battery pack overpressure relief. The company says the leak-check mechanism eliminates the need to install the vent valve as the final step… Read more »

DLR Institute leads project to research calcium-sulfur battery technology

DLR Stuttgart has announced that it will coordinate an effort to determine the potential of the so-called calcium-sulfur (Ca-S) battery as an alternative to lithium-ion batteries. The CaSino project, conducted by a consortium of five research institutions, two industrial companies and an industrial advisory board, is being funded with 3 million euros by the German… Read more »

Thermal runaway early detection: critical sensors and connections for safe battery management

Sponsored by TTI and Amphenol. Battery management systems (BMS)—the electronic brains that monitors and maintains lithium ion battery packs—are essential for the safe and efficient operation of the batteries powering a variety of applications, including electric vehicles. The growth of electric vehicle technology is driven by the desire for reduced emissions, quieter and less expensive… Read more »

Metis’s Battery Safety Sensor earns ISO certification, enters UK production

Metis Engineering has earned ISO certification of its Production Battery Safety Sensor, which designed to monitor the health of a lithium-ion battery pack and detect cell venting. The sensor was developed using ISO26262 processes, and has been tested to ISO Automotive Standards by Applus+ 3C Test, an independent testing house. Manufacturing of the production version… Read more »

Virtual Twin For Battery Engineering

With the rise of Battery Powered Electric Vehicle, our world is becoming more and more dependent on batteries especially in Transportation & Mobility and High Tech industries. These disruptive changes are driven by regulations and consumers demands (Range, cost, sustainability, etc.). The complete value chain from material suppliers to Battery makers to Automotive/High Tech OEMs… Read more »

ONE’s hybrid battery pack combines the best aspects of two chemistries to deliver 600 miles of EV range

Q&A with ONE CTO Dr. Steven Kaye. There is a wide range of characteristics that describe the performance of any given battery chemistry: energy density, specific energy, specific power, discharge efficiency, self-discharge rate, cycle life, calendar life, and—not the least important—cost. Some types of Li-ion chemistries are really good in a few characteristics but fall… Read more »

Leclanché develops new marine battery system

Leclanché, a Swiss energy storage specialist, has finished development of a marine battery system designed for electric and hybrid applications. It’s part of the Marine Rack System (MRS) product line, and will be available in 2023. The Navius MRS-3 is composed of 65 Ah G/NMC cells with laminated ceramic separators, Leclanché’s M3 Energy battery modules,… Read more »

Electrify America upgrades charging stations with solar canopies, battery storage, more customer amenities

Electrify America has announced “a new design vision” for some of its future charging stations, and will soon introduce a next-generation charger with updates to improve the charging experience. EA says its Charging Station of the Future will add design and comfort elements such as solar canopies and awnings, customer waiting areas and other customer-focused… Read more »

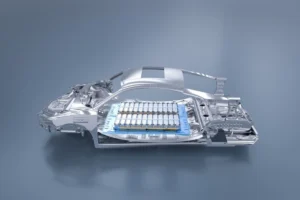

How to improve heat dissipation and EV battery lifetime

Sponsored by Von Roll Next-Generation Adhesive Products for Battery Applications How to improve heat dissipation, productivity and lifetime performance of battery modules and packs As the current trend is moving away from conventional ICE (Combustion Engine) power train systems to fully or hybrid electric systems, there is a strong demand and need for next-generation materials… Read more »