The Center for Energy Storage Technologies (CEST) is partnering with Hesse Mechatronics to develop battery technology with American vehicle and battery manufacturers. The aim of the partnership is to enable more seamless systems engineering capabilities, from cell testing and selection to module and pack design and prototyping. CEST plans to play an active role in… Read more »

Search Results Found For: "hesse"

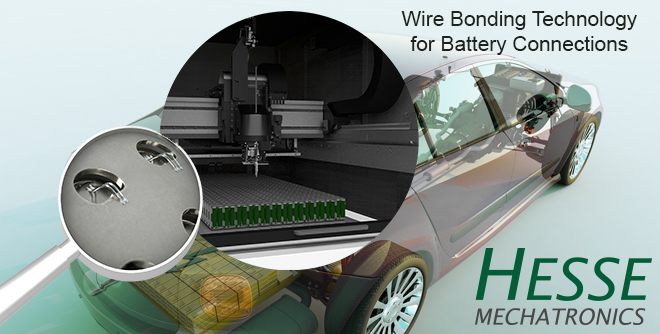

Interconnecting Your Battery Packs with Hesse Customer Solutions

Hesse Customer Solutions (HCS) has application labs that will assist you in the wire bonding, ribbon bonding, or smart welding of your battery packs. We can work with you on the initial design, materials selection, process development, and interconnection concepts. HCS has the capabilities to produce small prototype volumes of bricks and modules which could… Read more »

Wire bonding for EV batteries and inverters: application and process tips from Hesse Mechatronics

Sponsored by Hesse Mechatronics All electronic devices need to be connected electrically (and mechanically) and there are numerous ways of completing this task. Wire bonding is one type of interconnection. There are three types of wire bonding: thermocompression, thermosonic and ultrasonic. We will focus on ultrasonic wedge bonding with aluminium wire and discuss the wire bonding process… Read more »

Wire Bonding & Smart Welding Battery Modules for Prototype & Production

This presentation will outline how Hesse Customers Solutions and its partners, Acculon Energy and Calogy Solutions, could provide a wire bond and/or smart weld service to those companies who need battery modules made for prototype or production purposes. Presented by: Mike McKeown, Business Development Manager, Hesse Customer Solutions

Future-proofing battery testing for evolving EV technologies (Webinar)

As the EV market continues to grow exponentially, the need for new and innovative battery technologies becomes increasingly evident. To meet the demand for higher power, improved efficiency, and extended vehicle range, EV batteries are evolving rapidly, including advancements in solid-state, zinc-air, graphene batteries, and more. In this webinar at the Fall Virtual Conference on… Read more »

The benefits of smart welding battery packs

Sponsored by Hesse Mechatronics Benefits of Smart Welding There are many types of welding used for the interconnection of battery packs. Laser, resistance, spot, etc. are just a few of the common types. Smart Welding was developed by Hesse Mechatronics to offer an alternative option. Smart Welding is “wire bonding without the wire” as it continues to… Read more »

Guidelines For Implementing Wire Bonding Or Smart Welding For Battery Modules From Concept To Production

This presentation will outline the necessary steps to overcome challenges when trying to get your battery module ready for production when utilizing wire bonding or smart welding technologies for cell interconnection. Presented by: Mike McKeown, CTO, Hesse Mechatronics All Sessions: October 2022 Conference

Top 5 techniques for analyzing lithium battery cells

With demand for EV batteries seeing an impressive 30 percent year-over-year growth, pressure continues to increase for Automotive OEM’s and Tier 1’s to keep pace. Among the many levers you have available to ramp battery production, test coverage and strategy are one of the top 3 improvements that make a significant difference in your ability… Read more »

Smart welding battery packs

Sponsored by Hesse Mechatronics Benefits of Smart Welding There are many types of welding used for the interconnection of battery packs. Laser, resistance, spot, etc. are just a few of the common types. Smart Welding was developed by Hesse Mechatronics to offer an alternative option. Smart Welding is “wire bonding without the wire” as it continues to… Read more »