MP Materials has formed a public-private partnership with the US Department of Defense (DoD) aimed at developing a US rare earth magnet supply chain. Rare earth magnets are used in the majority of EV traction motors, as well as smartphones, robotics, and various defense-related applications. Over 90% of the world’s rare earth magnets are currently… Read more »

Search Results Found For: "recycling "

recell.store launches index to track end-of-life EV battery values

recell.store, a UK online marketplace for used electric vehicle batteries and a subsidiary of Altilium, has launched the All Battery Index (ABI), a monthly benchmark that tracks the market value of end-of-life EV battery packs in the UK. The ABI aims to provide a standardized reference for second-life use and recycling, addressing the lack of… Read more »

Ascend Elements wins $320-million grant to build pCAM battery materials plant in Poland

Poland’s Ministry of Economic Development and Technology has offered Ascend Elements up to 1.22 billion Polish złoty ($320 million US) to support construction of a precursor cathode active material (pCAM) manufacturing facility in the country. pCAM is a high-value, precisely engineered material used in the manufacture of lithium-ion batteries. Ascend Elements plans to commercialize its… Read more »

SWTCH Energy introduces anti-theft and vandalism solutions to protect EV charging hardware

In some parts of the world, vandalism of EV chargers is a real problem. Copper commands a pretty good price at recycling centers, and thieves use bolt cutters to remove the cables. If you think you’re mad when you pull up to a charger only to find that the cable is gone, imagine how the… Read more »

Henkel showcases new virtual adhesives, mica replacement safety coatings and structural adhesive debonding tech

At the upcoming Battery Show Europe, German adhesive specialist Henkel will showcase its latest advances in adhesives, functional coatings, thermal management and sealing solutions, which the company calls “key enablers of safer, more efficient and more sustainable EV batteries.” “At Henkel, we are collaborating closely with industry partners to push the boundaries of EV battery… Read more »

POSCO Future M adds new cathode and anode material technologies for EV applications

South Korean chemical manufacturer POSCO Future M is introducing new anode and cathode material technologies for EVs and adjusting its supply chain strategy for EV components. The company has developed a nickel-nickel single-crystal cathode material that maximizes energy density by increasing the nickel content to over 95%. POSCO Future M plans to secure mass production… Read more »

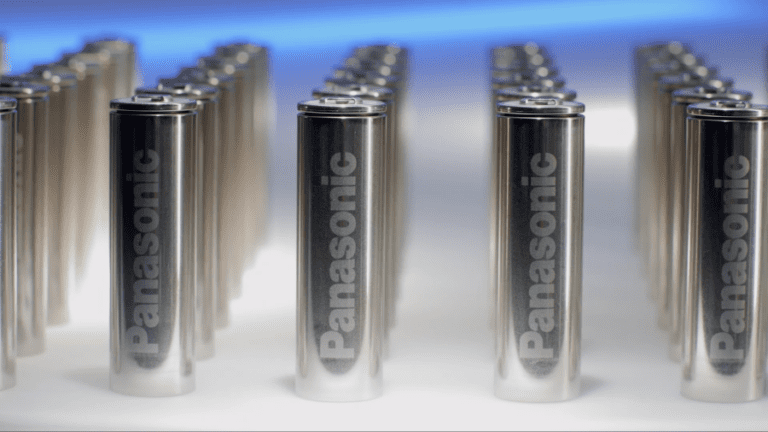

Panasonic Energy and Sumitomo Metal Mining collaborate to recycle nickel for Li-ion batteries

Japanese battery manufacturer Panasonic Energy has launched a recycling initiative for nickel used in lithium-ion battery cathode materials, in collaboration with Japanese non-ferrous metal refining and cathode material manufacturer Sumitomo Metal Mining. Through this new collaboration, battery scrap from Panasonic Energy’s Suminoe Factory in Osaka will be processed and partly recovered as nickel sulfate at… Read more »

Libattion opens battery upcycling facility in Switzerland

Zurich-based Libattion provides large-scale stationary energy storage systems made from used and surplus EV batteries. The company has opened a new battery upcycling production facility in Biberist, near Zurich. The new plant is designed for an annual capacity of 500 MWh by 2026, and has the potential to scale up to 1 GWh. The 7,000-square-meter… Read more »

CATL and NIO reach strategic cooperation on battery swapping

Chinese battery manufacturer CATL has signed a strategic cooperation agreement with EV manufacturer NIO to jointly build a battery swap network and promote the unification of industry technical standards. The companies aim to build a battery swap network for passenger cars and promote the popularization and upgrading of battery swap services. CATL will support the… Read more »

SK On and SK Enmove showcase battery immersion cooling

South Korean battery and trading company SK On is showcasing advanced thermal management technology with lubricant supplier SK Enmove. The immersion cooling technology for EV batteries circulates electrically insulating thermal fluids inside the battery pack to effectively dissipate heat. Since the coolant directly contacts the battery cells, it can more effectively suppress temperature rise compared… Read more »