The ABB FIA Formula E Championship has announced a partnership with Belgian materials technology and recycling group Umicore to recycle the Li-ion battery units and cells used during the first two seasons of the racing series. The batteries from Formula E’s first two seasons, which were built by Williams Advanced Engineering, have been collected and… Read more »

Search Results Found For: "battery recycl"

American Manganese begins pilot of battery recycling plant

American Manganese is developing a recycling process for Li-ion batteries, and processing partner Kemetco Research has begun processing a sample of cathode scrap material at the company’s pilot plant. The pilot plant will operate in five stages: Pre-treatment of cathode material Leach of active material Purification Recovery of base metals (e.g., nickel, cobalt, manganese) Lithium… Read more »

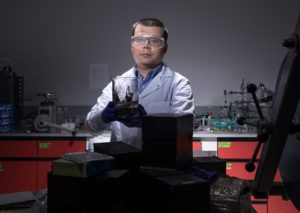

Worcester Polytechnic research team wins award from USABC for battery recycling process

An engineering research team at Worcester Polytechnic Institute (WPI) in Massachusetts recently won a million-dollar contract from the United States Advanced Battery Consortium (USABC) to develop an innovative process for recycling used Li-ion batteries. The team, led by WPI professor Yan Wang, it created a patented closed-loop recycling process that works like this: the batteries… Read more »

Axion, Aceleron and Aspire launch battery recycling and reuse initiative

Circular economy and resource recovery specialists Axion, Aspire Engineering and Aceleron have launched an initiative to tackle the growing number of end-of-life EV batteries. They are currently providing a recovery service that begins with Aspire processing the batteries for remanufacturing, reuse and recycling. Next, Aceleron tests and repurposes the batteries. If the batteries cannot be reused, Axion will then… Read more »

New EV battery recycling model quantifies cost and energy savings

What’s going to happen to all those lithium-ion batteries after they die? What’s the best way to recycle them? A new model developed at the DOE’s Argonne National Laboratory allows industry insiders to assess the money and energy savings from recycling EV batteries. ReCell, a closed-loop battery recycling model, offers preliminary estimates of total costs… Read more »

Toyota to source recycled EV battery components from Redwood Materials

Redwood Materials, the battery recycling company founded by Tesla co-founder JB Straubel, is focused on two of the most critical battery components: cathode active materials (CAM) and anode copper foil. Together, these two components account for the majority of the cost of a battery cell, the company explains, and at the moment, they are produced… Read more »

Dragonfly Energy manufactures lithium battery cell using high-purity recycled materials from Aqua Metals

Dragonfly Energy, maker of Battle Born Batteries, in collaboration with battery recycling pioneer Aqua Metals, has reported a significant advance in its quest for sustainable lithium-ion battery production. Dragonfly successfully used high-purity lithium hydroxide recovered by Aqua Metals from recycled lithium-ion batteries to manufacture a standard CR2032 battery cell using Dragonfly’s patented dry battery electrode… Read more »

DOE announces $192 million in new funding for EV battery R&D and recycling

The US Department of Energy (DOE) has announced more than $192 million in additional financing for recycling consumer product batteries, forming an advanced battery R&D collaboration and continuing the 2019 Lithium-Ion Battery Recycling Prize. The Advanced Battery R&D Consortium funding opportunity will provide up to $60 million to convene major EV manufacturers, universities, National Laboratory… Read more »

BASF establishes a co-located battery material production and recycling center

BASF, a chemicals firm, has opened a battery material production and recycling site in Schwarzheide, Germany. The automated production plant makes cathode active materials, and mechanically processes end-of-life batteries and battery production waste for the production of black mass, which contains lithium, nickel, cobalt and manganese. The factory will provide European cell manufacturers and automotive… Read more »

Faraday Battery Challenge funds projects on recycling, digital twins, innovative battery materials and production

Innovate UK‘s Faraday Battery Challenge will support 17 new EV battery initiatives with £27.6 million. The new projects will advance various types of EV battery technology, including digital twins, battery recycling and next-generation materials. All the projects integrate technological, market and commercial aspects designed to increase UK battery value chain competitiveness. OXLiD is investigating Lithium-sulfur… Read more »