Larger figure Researchers from South Korea’s Ulsan National Institute of Science and Technology (UNIST) and Stanford University have demonstrated the feasibility of a hybrid anode for Li-ion batteries using silicon-nanolayer-embedded graphite/carbon. In “Scalable synthesis of silicon-nanolayer-embedded graphite for high-energy lithium-ion batteries,” published in Nature Energy, Minseong Ko and colleagues explain that this architecture allows compatibility… Read more »

Search Results Found For: "graphite"

Chinese researchers develop aluminum-graphite dual-ion battery

A team from the Shenzhen Institutes of Advanced Technology of the Chinese Academy of Sciences has developed a novel, environmentally friendly low-cost battery. In “A Novel Aluminum-Graphite Dual-Ion Battery,” published in Advanced Energy Materials, Yongbing Tang and colleagues present a new aluminum-graphite dual-ion battery (AGDIB) that they say offers higher energy density than conventional LIBs, as… Read more »

Volt Carbon reports second US patent and new lithium battery test results

Canadian lithium battery developer Volt Carbon Technologies has received a second United States patent for its dry-separation graphite platform and reported new technical results from its lithium battery development program. Volt Carbon has received its patent titled “Method and System for Aerodynamic Air Classification” from the United States Patent and Trademark Office, issued as USPTO… Read more »

Sionic Energy and Group14 set new high-temperature benchmark for silicon-carbon anodes

Battery technology company Sionic Energy, together with Group14 Technologies, has announced the results of testing that demonstrates a new level of high-temperature stability for 100% silicon-carbon anodes in lithium-ion cells. By combining Group14’s SCC55 silicon-carbon anode material with Sionic’s proprietary Rapid Integration Silicon Platform containing 100% silicon-carbon (Si-C) anode and enhanced electrolyte, the companies “have… Read more »

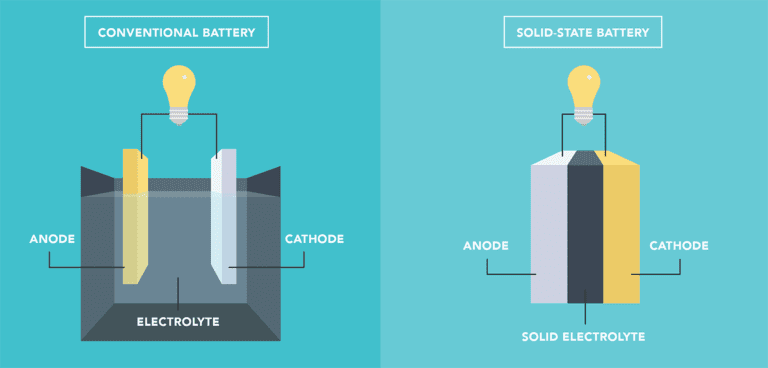

Operando X-ray tomography reveals silicon-electrolyte interface dynamics in solid-state batteries

Silicon anodes can greatly boost the energy density of all-solid-state batteries, but their large volume changes often cause contact loss with solid electrolytes. Si can store more lithium than graphite, but its volume can expand by as much as 410% during charging, generating mechanical stress that cracks particles and weakens their contact with the solid… Read more »

PEM tests feasibility of battery cells containing 80% recycled content

The Chair of Production Engineering of E-Mobility Components (PEM) at RWTH Aachen University is working with industrial partners on the Kreislauf.IN.NRW battery cell recycling research project. The project, funded by the Ministry for the Environment, Nature Conservation and Transport of the State of North Rhine-Westphalia, aims to investigate the production and functionality of cells containing… Read more »

Sakuu reports breakthrough in dry-processed battery cell, retaining 83% charge after 4000 cycles

Sakuu has announced that its Kavian additive manufacturing platform can dry-print lithium-ion battery cathodes with leading cycle life using existing high-nickel chemistry. The company claims that cells manufactured via Kavian’s fully dry process retained 83 percent of their original charge capacity after 4,000 cycles, surpassing typical standards for EV batteries. According to Sakuu, the tested… Read more »

Imerys and Shanghai ShanShan partner to supply Europe’s battery anode market

French industrial minerals company Imerys and its subsidiary Carbon Switzerland, which supplies conductive additives for lithium-ion batteries, have signed a strategic partnership deal with Shanghai Shanshan New Material to produce high-performance synthetic graphite anode materials in Europe. This partnership combines Shanshan’s anode production technology with Imerys’s graphite expertise, and will focus on optimizing products and… Read more »

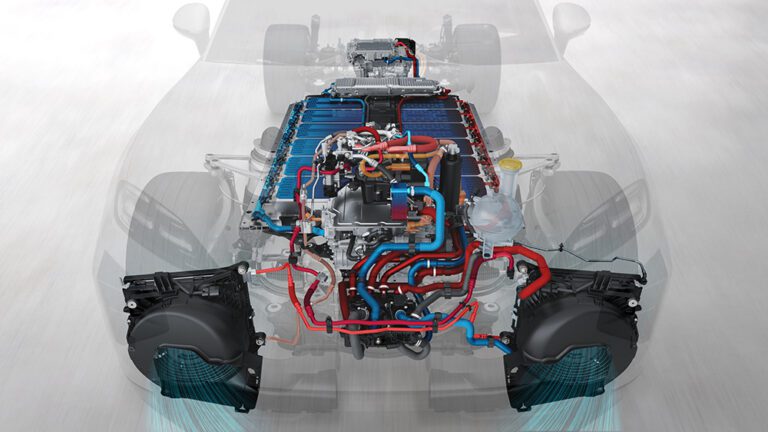

Porsche Cayenne Electric’s 800-volt architecture enables long range and super-fast charging

Porsche’s Cayenne Electric SUV, which will be launched in a few weeks, is based on a new version of the company’s Premium Platform Electric, and features a number of innovations, including a function-integrated battery, a dual cooling system, intelligent thermal management and an 800-volt architecture. According to the combined WLTP standard, the new SUV will… Read more »

Talga enters US battery anode market through partnership with United Catalyst

Battery materials and technology company Talga has signed a strategic cooperation agreement with United Catalyst, marking its entry into the US market and laying the groundwork for potentially building new battery graphite recycling and anode facilities. The three-year agreement combines UCC’s capabilities in automotive recycling with Talga’s expertise in battery graphite and anode materials. The… Read more »