Ford plans to invest $3.5 billion to build an LFP battery plant in Marshall, Michigan. BlueOval Battery Park Michigan will initially employ 2,500 people when production begins in 2026. The automaker will offer LFP (lithium iron phosphate) as a second battery chemistry option in addition to NCM (nickel cobalt manganese), allowing customers to choose an… Read more »

Search Results Found For: "cobalt"

How NanoGraf is commercializing the “world’s most energy-dense” 18650 battery cell with stable silicon oxide

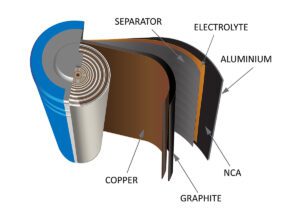

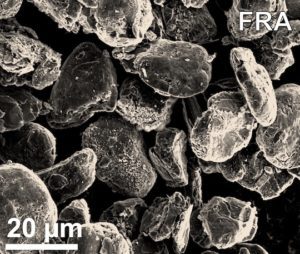

Q&A with NanoGraf COO Connor Hund Graphite, a pure form of carbon, is a critical material for battery anodes. Graphite’s physical structure allows it to store lithium ions, which merrily migrate to the anode when the battery is charged. Unlike cathodes, which can be composed of various combinations of chemicals (cobalt, nickel, manganese, lithium, iron,… Read more »

Redwood Materials to receive $2-billion DOE loan, begins production of anode foil

Redwood Materials, the battery recycling firm headed by Tesla alum JB Straubel, has received conditional commitment for a $2-billion loan from the DOE’s Loan Program Office as part of the Advanced Technology Vehicles Manufacturing Loan Program (ATVM). Redwood will draw upon this financing in tranches to support the phased construction and expansion of its battery… Read more »

A closer look at graphite—its forms, functions and future in EV batteries

Q&A with Graphex CEO John DeMaio Reading the EV press, you might assume that lithium, cobalt and nickel are the stars of the battery show—they get a lot of coverage, as pundits debate the relative merits of NMC and LFP cathode chemistries and agonize over looming shortages. Meanwhile, over in the anode, there’s an unsung… Read more »

Rice University announces new process to revive lithium-battery anodes for reuse

Rice University scientists have reported what they believe to be a partial solution to the mounting disposal problem of worn-out lithium-ion batteries. It relies on a unique “flash” Joule heating process they have developed to produce graphene from waste. The lab of Rice chemist James Tour is said to have reconfigured the process to quickly… Read more »

Verifying the origin of EV battery materials at the source: Traceability challenges, Part Two

Q&A with Bureau Veritas’s Stéphane Ponthieux Traceability—the process of documenting the source of a product and the links in its supply chain, has long been important in various industries (aerospace, food, pharmaceuticals). It’s now becoming a hot topic in the EV industry, because the Bipartisan Infrastructure Law (BIL) and Inflation Reduction Act (IRA), as well… Read more »

Documenting the EV battery material supply chain: Traceability challenges, Part One

Q&A with OPTEL’s Ken Fallu Traceability is a topic we’re beginning to hear a lot about in the EV industry. The term refers to a process for documenting the source of a product, along with all the links in the supply chain, and it has long been important in various industries. Perhaps the best-known examples… Read more »

Umicore and Nano One partner to develop production process tech for battery materials

Circular materials technology company Umicore and clean technology company Nano One Materials have signed a nonexclusive joint development agreement (JDA) on production process technologies for cathode active materials (CAM) for lithium-ion batteries. Umicore will evaluate Nano One’s patented M2CAM One-Pot process technology with the intention of integrating it with Umicore’s proprietary process technology for the… Read more »

EV Metals Group clears the way to build a battery material processing plant in Saudi Arabia

The EV Metals Group acquired the battery materials and technology business of Johnson Matthey in 2022. Now subsidiary EV Metals Arabia has advanced its plans to build a battery material processing plant in Saudi Arabia. EVM Arabia has been awarded an allocation of 127 hectares of land from The Royal Commission at Yanbu and a… Read more »

Aqua Metals begins pilot of AquaRefining battery recycling system

Nevada-based Aqua Metals has begun operating a pilot battery recycling facility at the Tahoe-Reno Industrial Center. Feedstock has been introduced into the automated system, enabling recovery of valuable critical minerals from spent lithium-ion batteries. The company’s Li AquaRefining technology is “a low-emission, closed-loop recycling solution capable of recovering all valuable metals, including high-purity lithium, manganese,… Read more »