US-based battery materials manufacturing technology company Sylvatex (SVX) has received $1.4 million in total project funding from the Department of Energy’s Advanced Research Projects Agency-Energy (ARPA-E). The original award included $500,000 of funding under the TINA Topic W, or Supporting Entrepreneurial Energy Discoveries (SEED), program. Supplemental funding of $982,000 for an additional two-year project will… Read more »

Search Results Found For: "Lithium Iron Phosphate"

Researchers demonstrate selective recovery of lithium from spent lithium iron phosphate batteries

A team from the Beijing University of Chemical Technology has used a formic acid-hydrogen peroxide system for selective leaching of lithium ions from spent lithium iron phosphate batteries. A paper on their process was published in the Journal of Power Sources. The team achieved optimal leaching conditions by single-factor optimization: formic acid concentration of 0.8… Read more »

Liacon launches new 12 V lithium iron phosphate battery

German battery manufacturer Liacon has released its new Group 31 lithium iron phosphate (LFP) 12.8 V, 150 Ah battery. Liacon’s LFP battery is designed to replace Group 31 lead-acid batteries for deep-cycle applications such as renewable energy storage, recreational vehicles and marine, according to the company. With 1,000 cranking amps, it can also start diesel… Read more »

Johnson Matthey acquires Clariant’s lithium iron phosphate business

Specialty chemicals firm Clariant has agreed to sell its Energy Storage line of business to Johnson Matthey for $75 million. The division is the world’s largest producer of hydrothermal lithium iron phosphate (LFP), which is used in EVs and stationary battery applications. The transaction includes a manufacturing facility in Candiac, Québec, and an R&D center… Read more »

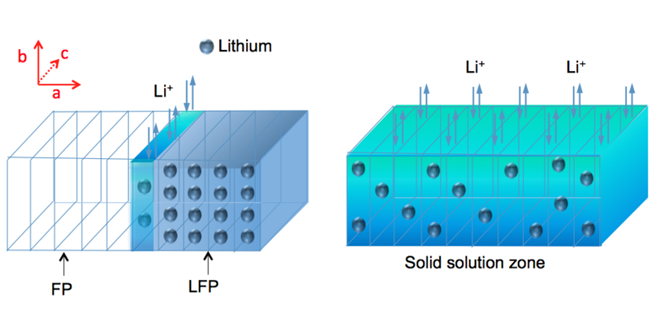

Lithium iron phosphate electrodes reveal exotic state of matter to MIT researchers

Transmission electron microscopy has allowed MIT researchers to directly observe a lithium iron phosphate (LiFePO4) electrode during charging, and they found that, just as suspected, a solid-solution zone (SSZ) forms at the boundary between lithium-rich and lithium-depleted areas, as lithium ions are pulled out of the electrode. The new findings, which appear in a paper… Read more »

Lyten secures US-produced sulfur to supply its lithium-sulfur manufacturing facilities

Lyten, which is developing lithium-sulfur battery manufacturing, has signed agreements with California Sulphur at the Port of Los Angeles and a Port of Stockton company for the supply of domestically sourced, industrial-grade sulfur for its manufacturing facilities in San Jose and San Leandro in California as well as its recently-announced gigafactory in Reno, Nevada. Lyten… Read more »

Lyten to acquire lithium-metal battery manufacturing assets from Cuberg

San Jose-headquartered Lyten, a manufacturer of advanced materials and sulfur-lithium batteries, plans to acquire manufacturing assets from San Leandro-headquartered Cuberg, including its lithium-metal battery manufacturing facility and cell-making equipment. Lyten plans to convert the facility to lithium-sulfur battery production and to invest up to $20 million in 2025 to expand its full Bay Area production… Read more »

GKN Hoeganaes to support First Phosphate’s LFP cathode materia development in Tennessee

GKN Hoeganaes, a division of GKN Powder Metallurgy, is collaborating with First Phosphate toward establishing a North American supply chain for lithium iron phosphate (LFP) batteries for EVs. The partnership follows GKN’s integration of First Phosphate’s magnetite into its proprietary Ancorsteel melting process. The process produces a high-purity iron powder, which serves as a precursor… Read more »

Lyten to build lithium-sulfur battery gigafactory in Nevada

Lithium-sulfur batteries, which feature high energy density, and don’t need problematic minerals such as nickel, cobalt, manganese and graphite, are widely seen as a possible replacement for today’s lithium-ion batteries. Lyten, which calls itself a “supermaterial applications company,” has long been a pioneer in Li-S technology. Now the company has announced plans to invest more… Read more »

Lyten ships lithium-sulfur cell samples to EV manufacturers

US-based chemical manufacturer Lyten has started shipping lithium-sulfur A sample cells to its investor Stellantis and other US and EU automotive OEMs for evaluation. The company has also started shipping samples to a major consumer electronics company and to US military agencies. It is targeting delivery of samples to more than 20 potential customers during… Read more »