American Resources, through its holding in ReElement Technologies, which is developing rare earth element (REE) and critical mineral refining capacity, has agreed to enter a joint venture (JV) with Exigo Battery Solutions to use ReElement’s rare earth oxide refining technologies within the US and India to produce purified rare earth oxides. Exigo will initially source,… Read more »

Search Results Found For: "Hydrometal"

Vianode and Fortum Battery Recycling to develop EV battery recycling value chain

Norwegian battery materials company Vianode and Finland-based Fortum Battery Recycling, which specializes in recycling valuable metals from EV batteries, have agreed to collaborate on developing a sustainable EV battery recycling value chain. Under the agreement, the two companies will work together to secure supplies of high-quality recycled graphite concentrate from Fortum’s hydrometallurgical plant in Harjavalta,… Read more »

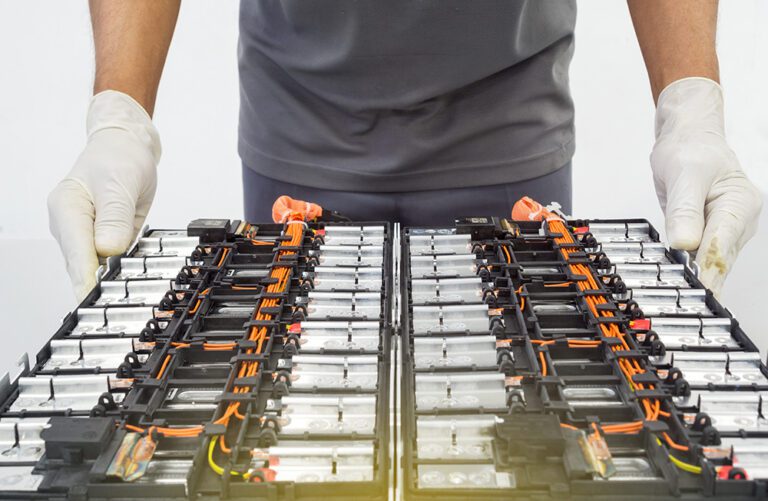

Blue Whale Materials partners with Call2Recycle for Li-ion battery recycling in North America

Lithium-ion battery recycling firm Blue Whale Materials (BWM) has formed a strategic partnership with Call2Recycle, a battery stewardship organization in North America. BWM’s sorting and recycling facility in Bartlesville, Oklahoma will receive and process batteries brought into Call2Recycle’s national network, which collects spent batteries across the US. The facility is already operational for sorting and… Read more »

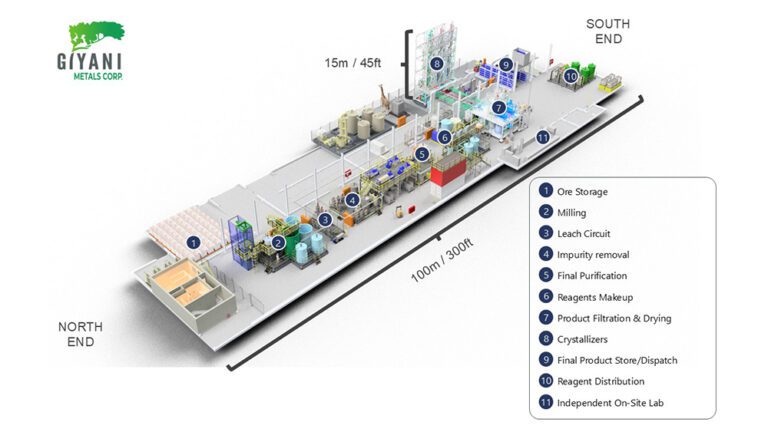

Giyani ramps up to produce battery-grade manganese at demonstration plant in South Africa

Giyani Metals, developer of the K.Hill Battery-Grade Manganese Project in Botswana, has started production at its demonstration plant in Johannesburg, South Africa. The company has developed a hydrometallurgical process to produce battery-grade manganese (HPMSM), a lithium-ion battery cathode precursor material. The production ramp-up has commenced and the plant is working towards initial production of battery-grade… Read more »

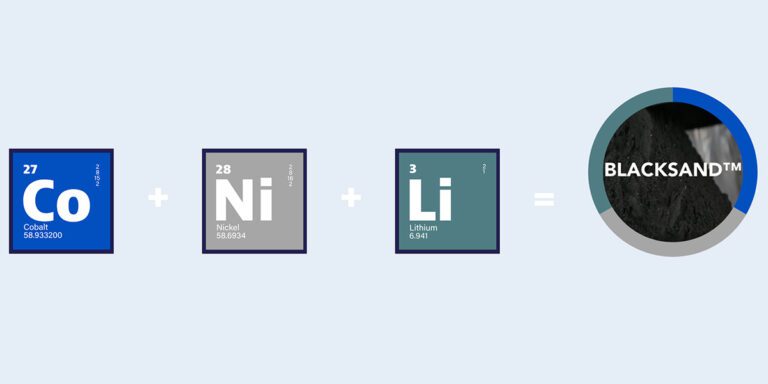

BMW and SK tes to expand high-voltage battery recycling

German carmaker BMW and South Korean technology firm SK tes plan to expand their closed-loop battery recycling system from Europe to the US-Mexico-Canada region in 2026. The recycling process recovers cobalt, nickel and lithium from used batteries to return them to the value chain to produce new batteries. BMW is directly involved in the process,… Read more »

Ace Green Recycling to build enormous LFP battery recycling facility in India

Ace Green Recycling, a provider of sustainable battery recycling technology, has secured a site in Mundra, Gujarat, to build what it says will be India’s largest battery recycling facility. The site is strategically located near major ports handling over 10% of India’s maritime cargo. The facility will build on Ace’s existing operations, which have been… Read more »

Mercedes-Benz opens battery recycling factory in Germany

Mercedes-Benz has opened its own EV battery recycling plant in Kuppenheim, Germany, which uses an integrated mechanical-hydrometallurgical process to recover raw materials. The plant has an annual capacity of 2,500 metric tons and an expected recovery rate of more than 96%. The plant carries out all steps, from shredding battery modules to drying and processing… Read more »

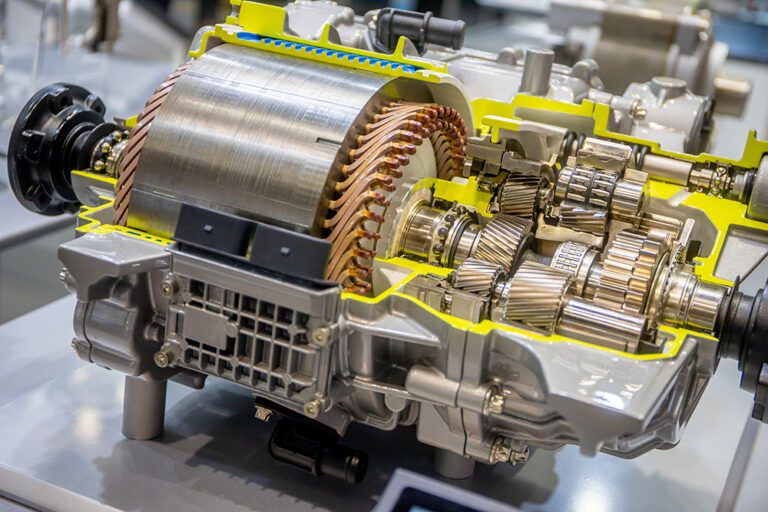

Cyclic Materials and SYNETIQ partner to recycle rare earth elements from vehicle motors

Canada-headquartered metals recycler Cyclic Materials has signed a collaboration agreement with SYNETIQ, a UK-headquartered vehicle salvage and recycling company, for the recycling of end-of-life electric motors containing rare earth elements. The motors to be supplied by SYNETIQ include hybrid and EV drive motors, as well as auxiliary motors found in all vehicles. To help meet… Read more »

Aqua Metals is building a more sustainable battery recycling ecosystem

Q&A with Aqua Metals execs Steve Cotton and David Regan Regardless of the claims made in Facebook memes, Li-ion batteries are eminently recyclable, and current recycling methods cause far less environmental damage than the well-documented depredations of the petroleum industry. However, as sustainability is central to the mission of the EV industry, we need to… Read more »

Altilium partners with Nissan on EV battery recycling project

Nissan’s factory in Sunderland, England is ending production of the LEAF after 13 years—but that doesn’t mean the automaker is giving up on the UK EV market. On the contrary, Nissan is planning to build two new EVs at the plant, and is also working on a UK battery factory. A further sign of Nissan’s… Read more »