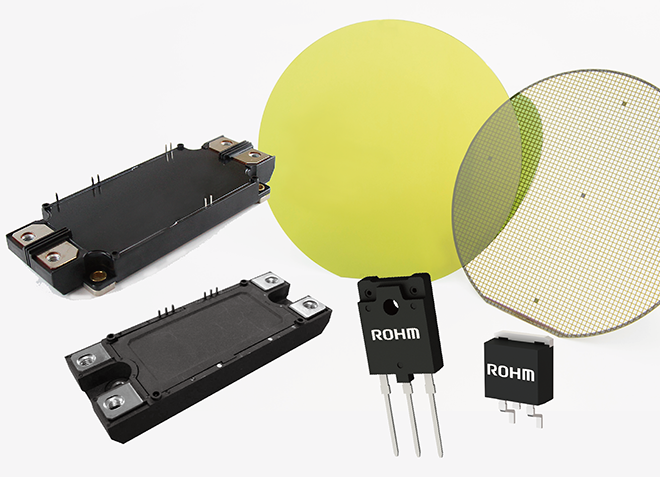

EV powertrain supplier Vitesco Technologies and silicon carbide specialist ROHM Semiconductor have signed a development partnership under which Vitesco will use ROHM’s SiC components to increase the efficiency of its EV power electronics.

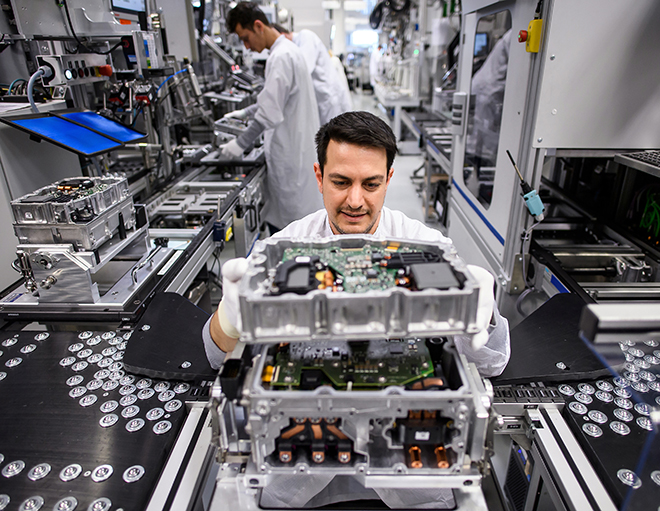

“Energy efficiency is of paramount importance in an EV. As the traction battery is the only source of energy in the vehicle, any losses caused by power conversion need to be minimized. We are therefore developing a SiC option within our modular power electronics system,” says Thomas Stierle, Executive VP at Vitesco.

“We are looking forward to cooperation with Vitesco,” says Dr. Kazuhide Ino, Director of ROHM’s Power Device unit. “We want to further improve the energy efficiency of the electronic system in EVs.”

Vitesco is currently developing and testing SiC technology in an 800-volt inverter concept to confirm the efficiency potential of the technology. The approach of this program is to look at the complete inverter and motor system and identify the best combination of device technology and switching strategy.

In this context, SiC semiconductors offer more efficient switching in the inverter (higher frequency, steeper switching slopes) and cause fewer harmonic losses in the electric motor. SiC technology is also a key enabler for super-fast 800-volt charging technology.

“The SiC option is a very promising future part of our modular power electronics system, comprising software, power output and switching strategy,” says Dr. Gerd Rösel, Vitesco’s Head of Innovation in Electrification Technology. “We will work with ROHM on 400-volt and 800-volt SiC inverter solutions.” Vitesco plans to start production of the first SiC inverter in 2025, when the demand for SiC solutions is expected to rise significantly. “Our partnership and development are perfectly on time,” says Rösel.

Source: ROHM