Sponsored by Thermo Fisher Scientific

Improve quality and performance of electrode coatings and separator films with LInspector in-line measurement and control system

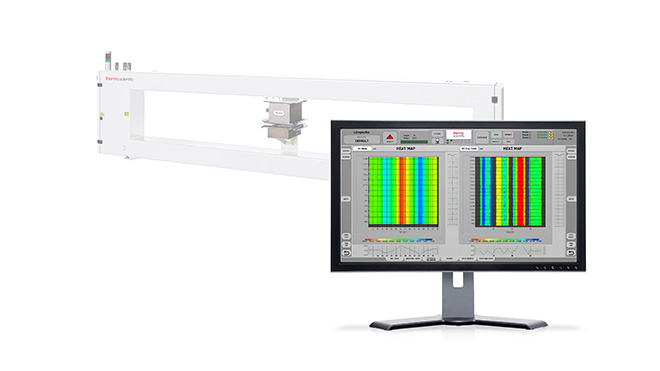

Thermo Fisher Scientific introduces the NEW Thermo Scientific™ LInspector™ in-line measurement and control system, specifically designed to increase quality and performance of lithium-ion battery electrode coatings and separator films.

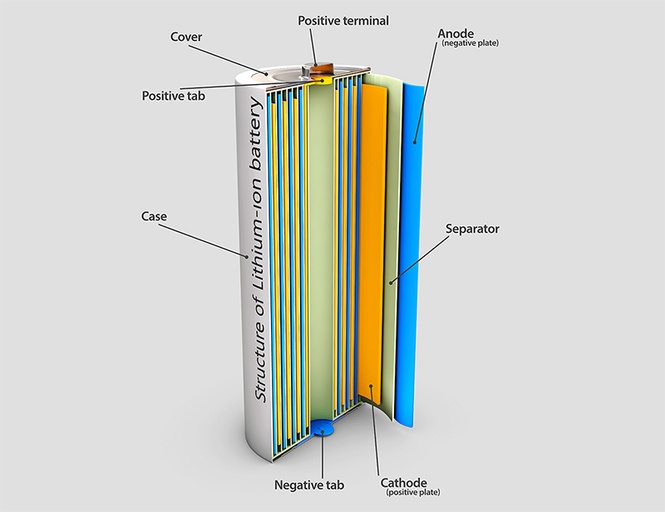

The production of lithium-ion batteries is rapidly increasing, driven by the growth in demand for electric vehicles and renewable energy storage. As a result of this, lithium-ion battery manufacturers need to scale their operations at an unprecedented rate, whilst maintaining quality, uniformity, traceability and safety in their battery products.

Specially designed for the different processes in lithium-ion battery manufacture

Building on 80 years of gauging measurement excellence, the LInspector measurement and control system is specifically designed to detect defects in lithium-ion battery electrode coatings, electrode calendering and separator films during the manufacturing process while reducing waste and improving battery quality.

Greater coverage, speed and resolution

LInspector measurement and control system offers a combination of improved basis weight determination, increased scan coverage, measurement precision, speed and sensor accuracy, together with novel remote instrument health and status monitoring capabilities. These developments enable coating and thickness control with exceptional accuracy and ensure superior battery quality, allowing manufacturers to confidently deliver superior quality lithium-ion battery products at scale, while reducing wastage of raw materials. The new system also includes innovative diagnostic display screens and data reporting purpose-built for battery factory environments.

See more, waste less

LInspector measurement and control system ensures process efficiency, allowing manufacturers to confidently deliver high-quality lithium-ion battery products at scale.

- Small measurement spot size and high sampling rate for unmatched streak resolution and analysis of coating edge defects

- Precise measurement and automated slot die control to ensure adherence to the most challenging product specifications

- Precise patch width dimensional analysis to avoid excess wastage of electrode material

Robust technology

The Thermo Scientific™ INTEGRA™ O-Frame Scanner is part of an intelligent network and provides exceptional value with high-speed scanning for greater measurement coverage. The rugged exoskeleton design of the INTEGRA O-Frame scanner provides high stability and isolates mechanical and electrical components from the environment within its thick plate walls. It also uses laser aligned rails and bearings to ensure precision head alignments and negligible run outs.

The Thermo Scientific™ INTEGRA™ C-Frame Scanner combines robust design and high acquisition speeds for best-in-class measurement performance in electrode calendering applications. Its single component aluminum construction is self-calibrating and provides high rigidity and temperature stability. The INTEGRA C-Frame Scanner has integrated precision guide rolls to ensure accurate measurement in real time. It conforms to clean room specifications and is available in single or double frame options for narrow and wider lines.

Make control decisions faster

LInspector measurement and control system offers a suite of advanced applications packages for lithium-ion battery manufacturing, including:

- Stripe/patch/pattern statistics

- Roll report

- Stripe/patch/pattern edge zoom

- Heat map display

“Lithium-ion battery manufacturers need confidence that they can detect exceptionally small defects in their products. LInspector measurement and control system enables battery manufacturers to consistently qualify the thickness and coating uniformity of battery electrodes during the production process at faster speeds and with greater resolution than ever before,” says Tam Nguyen, Senior Product Line Manager. “In addition to exceptional precision and control, the LInspector measurement and control system has intelligent IPM with secure data archival and full traceability of product defects. These innovations will enable battery manufacturers to improve their product quality and prevent defective batteries from reaching cars, clean energy storage systems and consumer electronics.”

Ready to learn more? Contact a specialist in our team today! Or find out more at thermofisher.com