Magnetic sensors have several automotive applications, including determining the positions of clutch pedals, engine strokes, and valves. However, their use has been limited to linear position measurements. The current standard, Hall sensors, can only detect changes in the magnetic field perpendicular to its chip. TDK Corporation has introduced the new HAR 379x sensor, which uses its Redundant 3D HAL technology to provide readings in the x,y and z coordinate planes, making angular measurements possible.

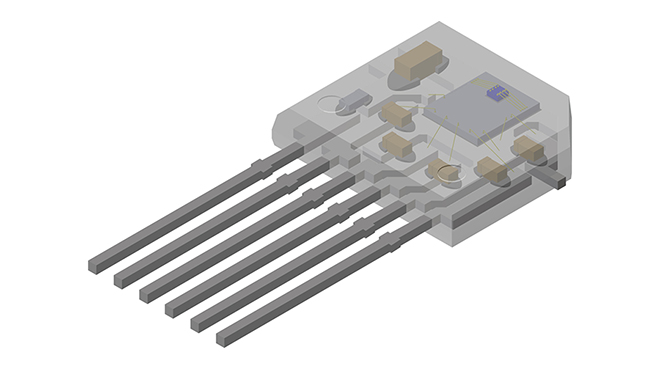

What does this mean? Measurements can now be taken on rotating shafts from 0° to 360°. This is useful for rotary shifters with push functions and rear axis steering systems. The new sensors are made by combining two Hall elements while keeping them “mechanically separated and electrically insulated from one another.” TDK claims that this”Redundant sensor solution” will reduce system costs while being more dependable, as it has smaller PCBs and fewer solder joints.

Here is a summary of the HAR 379x’s features:

- Very low angular error of ±1.2° at 30 mT amplitude

- End of shaft and off-axis 360° angular measurement

- Direct measurement of magnetic field amplitude (BX, BY, BZ)

- Transmission of angle and amplitude information via fast channel of SENT

- Digital output formats (PWM and SENT SAE J2716 rev. 2016)

- Addresses safety-critical applications according to ISO 26262 rules

- Full redundancy due to Dual-Die approach

- Suitable for automotive applications, thanks to a wide ambient temperature range from -40° to 150° C

Source: TDK