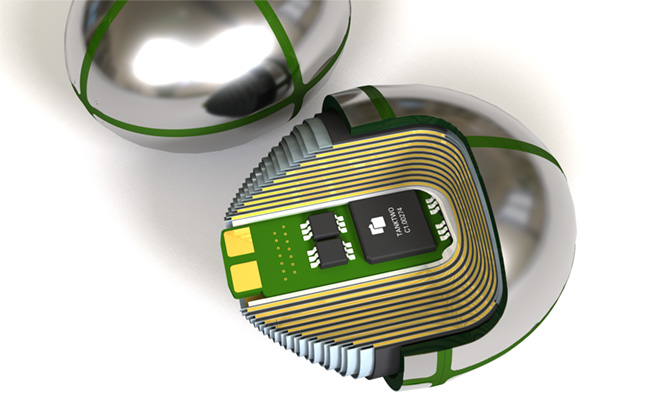

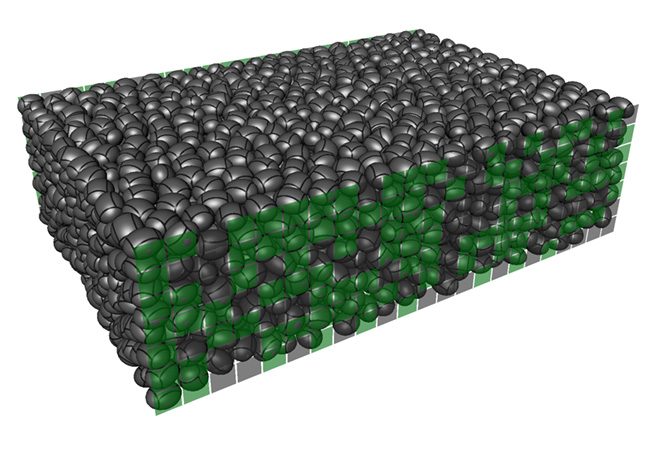

Tanktwo’s smart cells represent much more than another concept for battery swapping. The system is based on a tank full of “string cells,” which contain lithium-ion battery materials as well as electronics for sensing, routing, and communications.

Understanding Tanktwo’s system requires throwing out any preconceptions of how battery packs are supposed to work. Tanktwo CEO Bert Holtappels told Charged that the simplest way to get the point across is to emphasize the upfront savings an EV manufacturer can pass on to its consumers by using intelligent string cells. “What will really make this thing work is the business model for our industrial partners.”

Traditional battery packs are designed with a lot of extra capacity that is not accessible while driving, in order to allow for degradation and to protect cells from safety hazards and premature wear. Tanktwo claims it can reduce that extra capacity significantly.

“In a traditional pack, module or cell variance is the enemy, to be avoided at all costs,” Holtappels explained. “Tanktwo string batteries, however, work efficiently even if cell performance varies widely. When higher variance can be tolerated while retaining most of the efficiency, the state-of-charge (SOC) limits can be widened.”

“Not only can the spread be wider, but a significantly deteriorated cell, like one that has lost 70% of its design capacity, can still contribute to pack capacity. This means that string cells, even when employing identical battery chemistry, have a longer useful life or can be pushed harder, hence a pack can be smaller.”

“Every string cell contributes to the best of its ability at all times,” said Holtappels. “Old and new string cells, cells of different capacities – and even chemistries, in theory – can be mixed without limitations. And we make capacity restoration very easy. So instead of over-dimensioning to prevent warranty liability, you can restore capacity in a few minutes only if and when it happens. We make a shop-vac-like analyzer that will remove string cells that do not meet certain criteria. Replacing the lowest performers with new cells is done in minutes, restores pack performance to the required level, and costs a fraction of a total pack.”

Doesn’t adding intelligence and switching capabilities to every cell increase pack overhead and cost? Holtappels explained that the potential savings outweigh additional costs. “The numbers work out in our favor for a few reasons. The components added to make cells intelligent cost only cents per cell in volume, as the CPU and memory footprints are very modest by today’s smartphone standards. But the immediate efficiency gains I described are on the order of tens of percent. So from day one our customers win.”

The full interview with Tanktwo’s CEO is available in Charged – Issue 21.