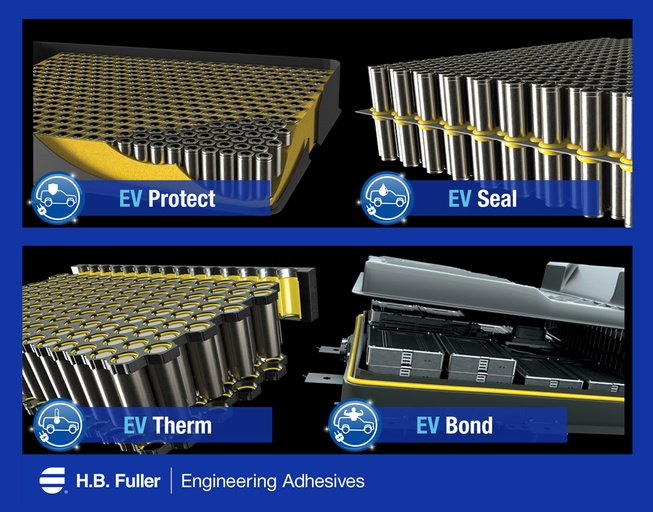

Join this webinar session at our Spring Virtual Conference on EV Engineering, presented by H.B. Fuller Company, where we will discuss the process of constructing a battery module and the use of innovative adhesive, sealant, and encapsulants for each stage of construction. We will go step by step from bonding cells to carriers all to closing and sealing the battery module. Along with each stage of module construction, we will review the different adhesive technologies specifically designed for each function. These next-generation innovative adhesives have an array of benefits including ease of manufacturability, reduction of weight, optimized thermal management, and improved safety.

After the presentation, join us for a live Q&A with H.B. Fuller’s Business Development and Applications Engineering team.

Other sessions at our Spring Virtual Conference include:

What Does The Tg Of ARALDITE And ARATHANE Thermosets Mean For Your EV Application?

Huntsman Advanced Materials has developed a wide portfolio of casting and impregnation resins for EV applications. The Tg can act as a very powerful (and also misleading) physical quantity to describe those epoxy and polyurethane resins.

Huntsman will present the basic principles of the Tg and its relation to material properties below and above the Tg. For instance, the more flexible thermoset network above Tg directly impacts absorption of oil and water.

For its product range of epoxy and polyurethane resins, the Tg start at -60°C and can be as high as 200°C. This allows us to define 3 groups of materials:

1. Tg below the minimum operating temperature: Tg_MIN

2. Tg within the operating temperature: Tg_MID

3. Tg above the maximum operating temperature: Tg_MAX

For each group of material, Huntsman will give examples of typical EV applications and suitable products and production processes:

1. Tg_MIN casting resins for battery applications

2. Tg_MID potting and impregnation resins for stators and electronics

3. Tg_MAX potting and impregnation resins rotating parts like rotors

Register here to learn more—it’s free!

See the full sessions list for the Spring Virtual Conference on EV Engineering here.

Broadcast live April 4 – 7, 2022, the conference content will span the EV engineering supply chain and ecosystem including motor and power electronics design and manufacturing, cell development, battery systems, testing, powertrains, thermal management, circuit protection, wire and cable, EMI/EMC and more.