Commercial vehicle OEM Proterra is collaborating with construction and mining equipment specialist Komatsu to electrify next-generation underground mining machines using Proterra’s battery technology.

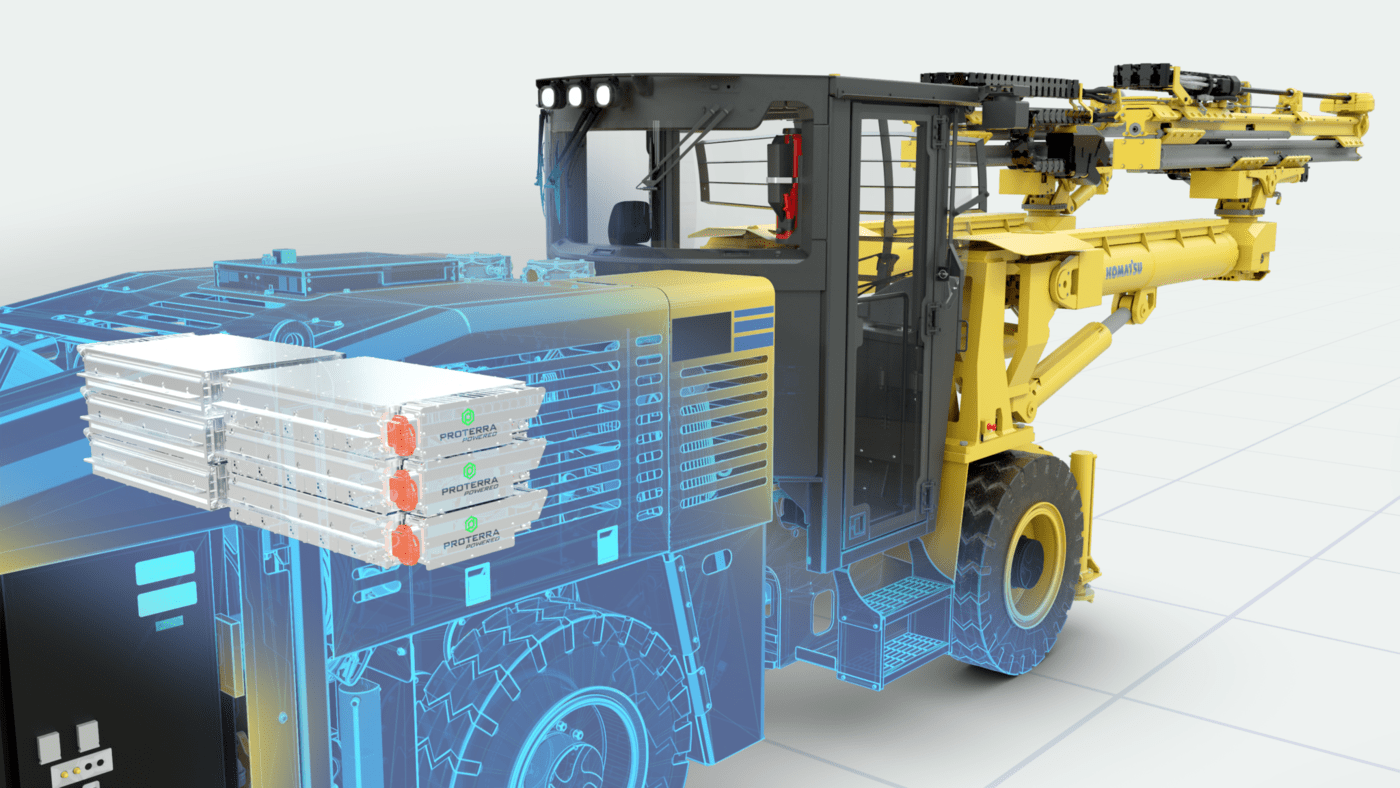

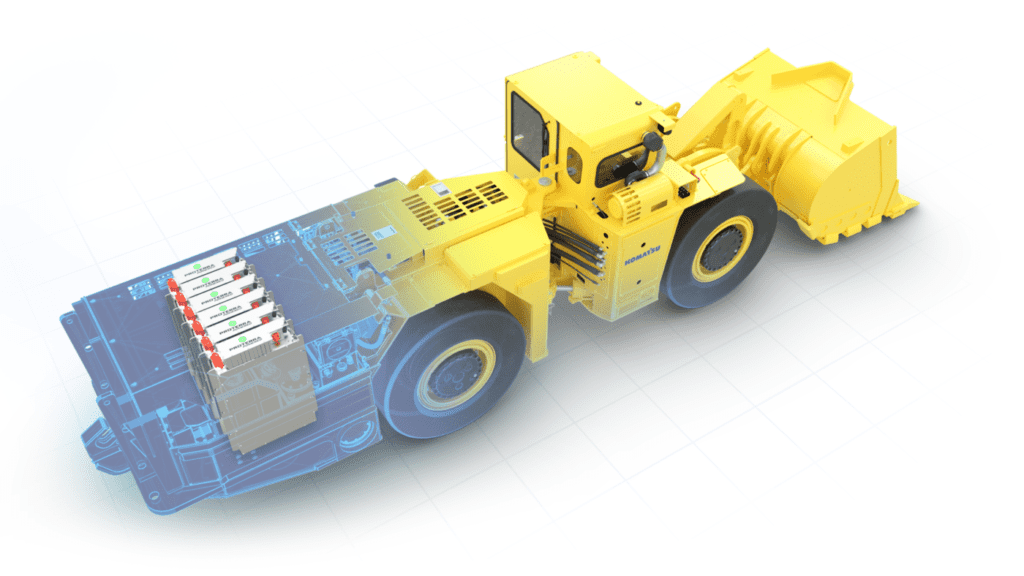

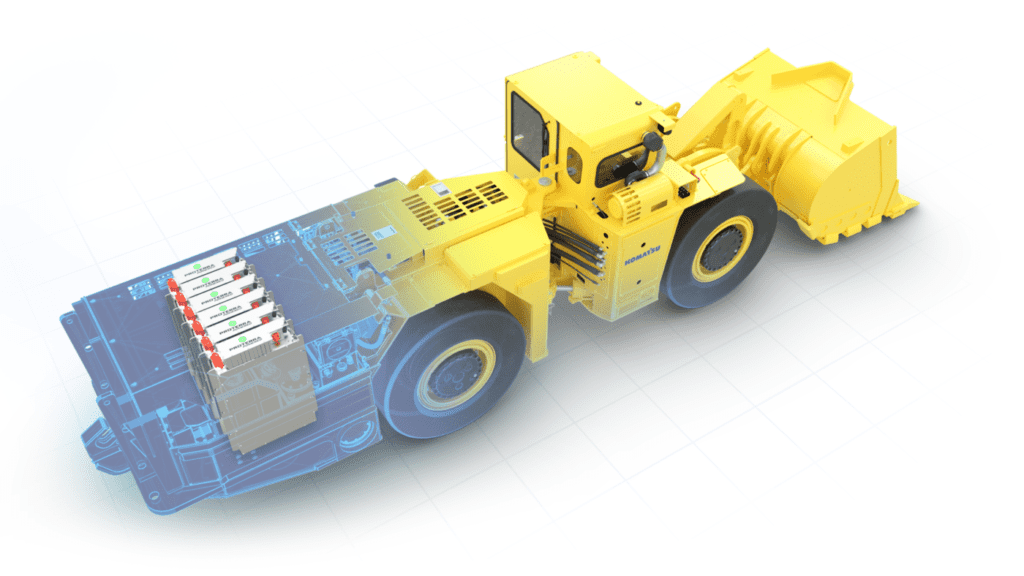

Proterra will supply its H Series battery system technology to Komatsu for the development of battery-electric Load Haul Dump (LHD) vehicles, drills and bolters for underground hard rock mining. Komatsu plans to develop prototype machines this year, and expects to begin commercial production in 2022.

This is Proterra’s first foray into the world of underground mining, but it’s the second collaboration between Proterra and Komatsu. In January, the two companies announced a partnership to develop a battery-electric middle-class hydraulic excavator.

Komatsu has been trending green for some time—it launched a line of hybrid hydraulic excavators in 2008. This year, Komatsu announced an alliance with key customers to develop a new generation of zero-emission mining equipment and infrastructure. The alliance’s initial goal is to advance Komatsu’s power-agnostic truck concept for a haulage vehicle that can run on a variety of power sources, including diesel-electric, trolley (wired electric), battery-electric, and hydrogen fuel cells.

Proterra says its battery systems offer an outstanding application for confined, underground mining settings in which safety and durability are of utmost importance, and also help to mitigate air and noise pollution. Proterra performs rigorous testing to ensure that its battery packs can withstand tough conditions and meet or exceed the latest functional safety standards. Proterra battery systems incorporate liquid thermal conditioning, monitoring sensors throughout the battery pack, and active and passive protective features such as passive propagation resistance to isolate individual battery cells in the rare case of a thermal event.

“The benefits of zero-emissions, battery-electric vehicles extend far beyond our roads and cities,” said Gareth Joyce, President of Proterra. “Switching to battery-electric technology means helping protect clean air for those working in underground mines while delivering a high-performance technology solution where safety and reliability are paramount.”