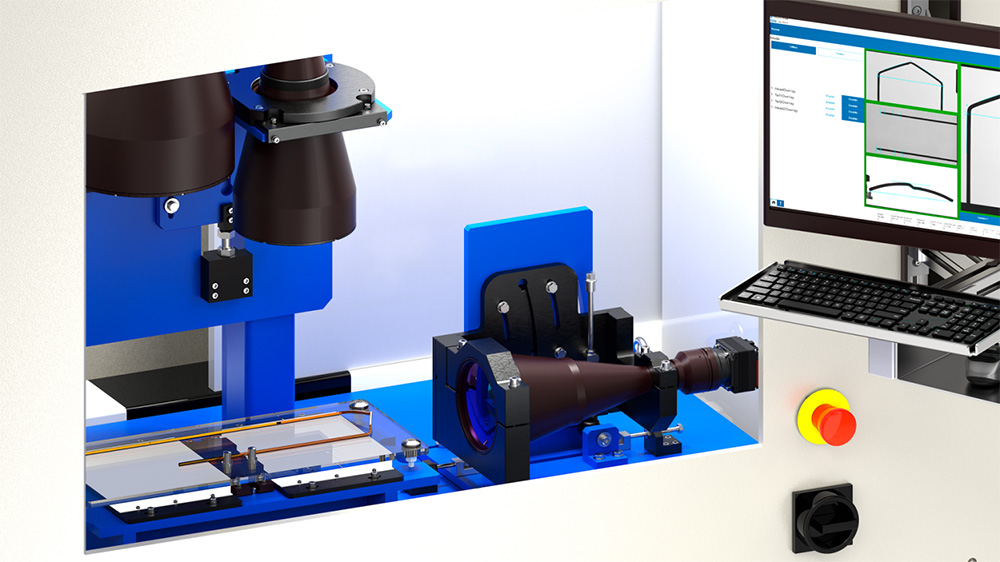

Measurement, inspection and test technology company Marposs has announced a new optical inspection system for stator hairpins.

The company says, “Traditional contact systems, or use of reference profile masks/jigs, can easily deform the intended shape.” The new system is available in a manual-loaded test bench version for workshops and labs or in a version that can be integrated into an automated production line.

The new system is composed of three proprietary high-resolution cameras with telecentric lenses. It measures the head, tail and roof of hairpins by placing them on tempered glass with reference points for pin placement, snapping three images with one image per camera and using software to detect points and dimensions. “The entire measurement cycle is accomplished in only five seconds,” according to the company.

Source: Marposs