The aluminum-air battery, which uses a catalytic air cathode and an aluminum anode, has intrigued researchers for some time, because of its high theoretical specific energy. However, the problem is overcoming parasitic hydrogen evolution caused by the corrosion of the aluminum anode during discharge.

In “Improvement of Aluminum-Air Battery Performances by the Application of Flax Straw Extract,” a team from Israel and Russia reports that they were able to substantially improve the performance of Al-air batteries by using flax straw extract as a corrosion inhibitor.

“One of the possible approaches is to mitigate Al corrosion by the addition of inhibitors to the alkaline media,” write the researchers. “However, unlike the inhibition protection of technological equipment (pipeline, heat exchanger, and tubes), there are additional and unique requirements for anode corrosion inhibitors in batteries. In the case of the Al anode, it is beneficial to achieve corrosion protection by the suppression of only the cathodic process (hydrogen evolution reaction). The anodic process should remain intact, similar to that that occurs in the inhibitor-free solution, as the suppression of the anodic process by the inhibitors may affect the performance of the entire battery negatively.”

The team found that flax straw extract suppressed Al corrosion with 50% efficiency at a low concentration (3% by volume) in the alkaline solution. “For practical battery applications, only low concentrations of an organic inhibitor should be added to the electrolyte. This is a prerequisite to avoid drastic damage to the electrochemical performances (working potential, capacity, and rate capabilities).”

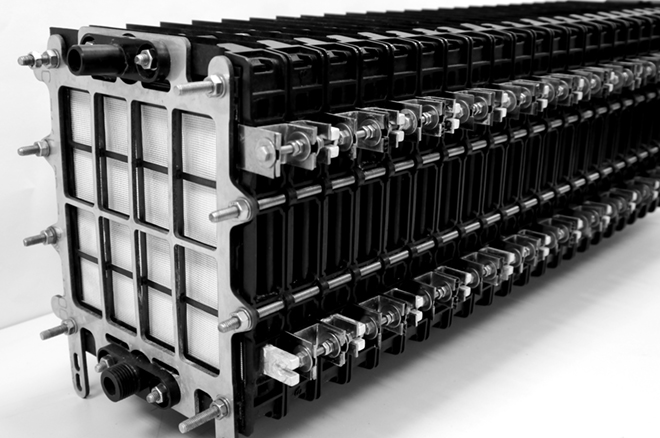

SEE ALSO: Phinergy CEO on aluminum-air batteries and 1,000-mile range-extended EVs

Source: Green Car Congress

Image courtesy of Phinergy