A new EPIC project coordinated by Karlsruhe Institute of Technology (KIT) is aimed at accelerating the drying of electrodes for lithium-ion batteries, increasing the energy efficiency of this process and reducing production cost. KIT says innovative electrode drying management can reduce the cost of battery production and improve environmental performance.

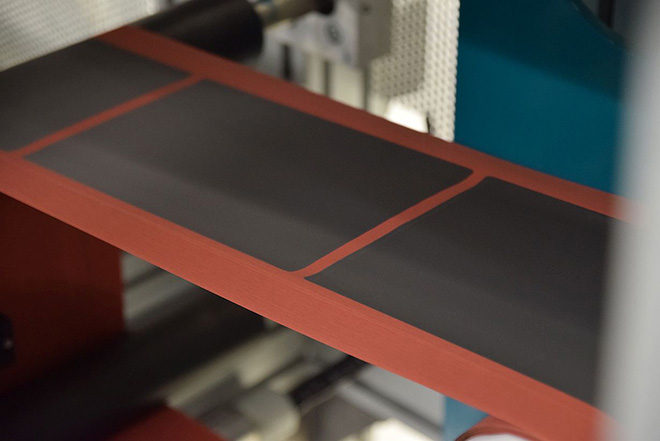

The quality of Li-ion battery cells depends on the electrode layers that store the battery’s energy. Both the anode and the cathode material are applied in a thin layer of water-based or solvent-based paste onto a conducting foil made of copper (anode) and aluminum (cathode). Researchers of KIT’s Thin Film Technology (TFT) group developed a coating process that allows electrodes to be produced in less time than with traditional methods.

“It is important to analyze the individual process steps together and to consider interactions,” said the project’s coordinator, Professor Wilhelm Schabel. Other partners include Professor Jürgen Fleischer from KIT’s wbk Institute of Production Science, as well as researchers from the Center for Solar Energy and Hydrogen Research Baden-Württemberg (ZSW) and the Technical University of Braunschweig.

SEE ALSO: Maxwell’s “dry electrode” process could save Tesla big bucks on battery manufacturing

EPIC focuses on energy-efficient drying technologies and optimal moisture management for the materials used along the process chain, from drying to cell assembly. TFT studies conventional drying processes, high-power radiators and drying management in general. “Higher coating speeds are particularly attractive when drying time can be reduced and the expensive drying line does not have to be extended,” said TFT’s Dr. Philip Scharfer.

wbk studies drying directly in the cell stack prior to electrolyte filling, as well as adjustment of the required cell moisture without prior drying in the cell stack directly before electrolyte filling. wbk, in cooperation with researchers from the Technical University of Braunschweig, evaluates how the drying intensity and duration influence cell properties. ZSW will model the production of industry-scale batteries and the exposure to moisture under a controlled production atmosphere on a scale comparable to that of series production.

The different approaches to production will be evaluated by the project partners using suitable process-cost models, and they will make recommendations for transferring the process to the industrial scale. In addition to energy and resource efficiency and battery cell quality, they will also consider environmental compatibility. The latest findings in production technology will be incorporated directly in the Post Lithium Storage (POLiS) cluster of excellence, in which KIT will develop future batteries together with Ulm University and ZSW.

SEE ALSO: Fraunhofer’s dry coating process for electrodes could make cell production in Europe economical

Source: KIT