One size serves all.

When interviewing the founders of technology startups, we often hear a common narrative as they recount the inception of the company. They go shopping for a product, find the available options lacking and then ask themselves, “Why doesn’t a better solution exist?”

That’s Frank Gangi’s story. He bought a Tesla Model S and went looking for a high-power charging station. Tesla offered its Wall Connector, capable of 80 A (240 V) charging at home, but Tesla uses a proprietary plug and Gangi wanted something that he could also use with other EVs.

At the time, he found only one product for sale in the US that had high enough power to charge his Model S at its maximum AC charging speed and used a J1772 connector (which will work with every plug-in vehicle, including his Tesla via an adapter).

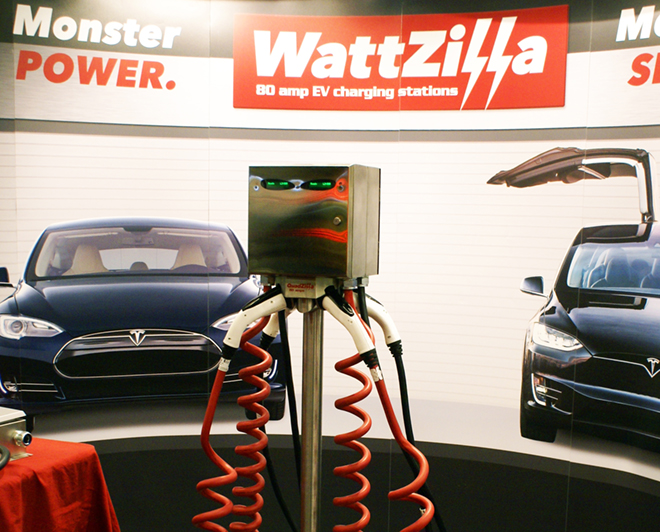

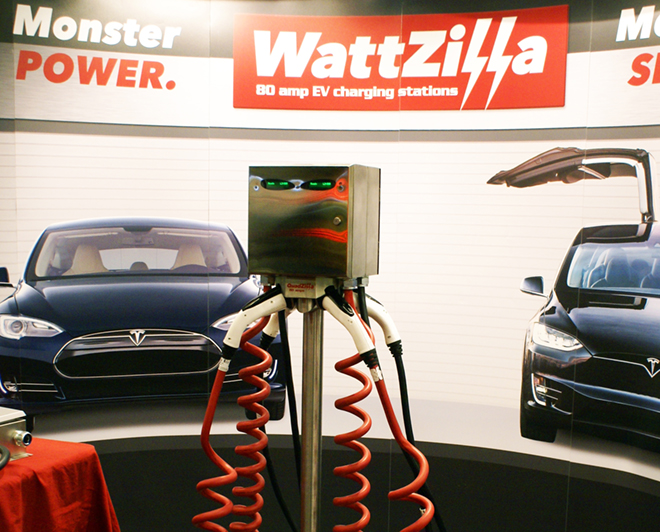

So, about three years ago Gangi joined Liquid Sky Technologies and began developing its WattZilla line of 80 A J1772 charging stations.

Charged recently talked to Gangi to learn more about the company’s philosophy, EVSE designs and future product plans.

Charged: Other than Tesla, there aren’t any passenger plug-in vehicles on the market today that are capable of charging at 80 A, 240 VAC (19.2 kW). So why design an EVSE with that much power?

Frank Gangi: We design WattZilla products to be the last charging station you’ll ever have to buy, because we know for a fact that many more EVs are going to have higher power on-board chargers in the near future. We know this about some of the new startups building EVs, and companies like Porsche, Audi and Ford have all indicated that they will soon up the ante on AC charging.

All the signs indicate that this is where the future is headed, and it’s simple math. In order to get the faster recharge times, it’s all about kilowatts. If you look at it in terms of infrastructure in the US, most people’s homes have somewhere between 100 and 225 A service. So, you’re not going to be able to do more than 80 A charging. And we’re right there, already serving the market.

If today you’re charging a Prius Plug-In at home and next year you’re going to buy a Tesla, either one is covered with our products. We’re unique in that we’re aiming for a part of the market that really wants a quality charging station that will never be obsolete.

Charged: Do you design and build the products in-house?

Gangi: Absolutely. Before this I was in telecom manufacturing, where I developed a strong belief that we can design and build anything in this country. It’s just a matter of will, not a lack of ability. We are based in the Northeast, where there is every skill set you need to help you build whatever you want.

And when we tell people that our products are the only chargers you’ll ever have to buy, that’s from a quality-of-design standpoint as well as in terms of your future power needs.

We use the best components we can find. For example, all our circuit boards are gold-plated for corrosion resistance, and our internal wiring is military-grade silver-plated copper with Teflon insulation. We use nothing but high-grade 316 stainless steel to construct our enclosures for all-weather use. They are corrosion resistant in harsh environments, so you can actually plant them in seawater and they will not corrode. We cut our own silicon gaskets to seal the door, because we want it to be as impervious to water, oil and UV as possible. We also nickel-plate the door because it’s gorgeous, and we want you to be proud to have it hanging in the garage. It’s literally bulletproof. We have a video on our site of it being shot at a rifle range while it’s charging a car.

We design products to a very high quality standard because we don’t want customers to ever come back and say our device failed under circumstances that it should not have. We have a 39-month warranty, and as far as I know that’s the longest in the industry.

The term charger is used incorrectly for EVSE all the time. The AC charger is in the car. What we’re really designing is a piece of life safety equipment, so we also set out to be the best at safety. Most people agree that EVSE stands for Electric Vehicle Service Equipment, but we think it’s more accurate to define it as Electric Vehicle Safety Equipment.

If you crack open pretty much any other EVSE on the market you will find fuses inside. Everyone that uses them does so in order to pass what’s known as the welded contact test, which you need to pass in order to gain UL certification. During the test, a big piece of metal is used to short the output of the EVSE’s relay. Then they command the charger to start charging, and when the contactor closes, all the electrons in the entire neighborhood are trying to rush through it because it’s a dead short and the path of least resistance. The system is supposed to detect that short and then open the relay fast enough that you do not weld the contact shut. If it welds shut, you are required to install a secondary means of protection – i.e. fuses.

When our device was tested in the lab, it detected the short and opened so quickly that UL thought that the contactor had never closed in the first place. They said, we’re not seeing any current flow, and normally there will be something like a 600 A spike. They usually see big current spikes because devices are so slow to open that it allows it to build up. Thankfully, the guys from the third-party testing lab backed us up with more granular data and showed that we actually had a 20 A flow across the relay before it drops to zero when it opens. They said it was the fastest detection and mitigation they have ever seen. One of the technicians commented that we had passed a very difficult test on the first attempt, one that billion-dollar companies failed repeatedly. I told him that just because they had more money than us didn’t mean they were smarter than us. So, since it is a piece of life safety equipment, we feel we did a fine job detecting/mitigating a fault that could have been life-threatening as quickly as we did.

Charged: You sell charging stations, but you also sell a control board for other people to build their own charging stations around.

Gangi: Yes. Our J1772 EVSE line starts with the WattZilla – an 80 A unit that’s designed for interior use and is flush mounted in between two studs in the wall. The WattZilla UNO is also an 80 A single-plug unit, but it’s designed to be wall- or pole-mounted for interior or exterior use.

Then, we have the WattZilla DUO and QuadZilla units that can provide 80 A charging to two and four vehicles simultaneously. Those require one 100 A supply circuit for each plug. We also have a version of the DUO that works on a single 100 A feed and mixes the power so that it can put out as much as 80 A mixed between the two sides. It’s all done automatically through our current-sharing software based on the needs of each vehicle.

On the industrial truck and bus side, we have the WattZilla Gorilla, with two receptacles and the ability to deliver 400-480 V 3-phase and 63 A per phase. Each of the receptacles can deliver 52.5 kW, for a total of 105 kW of power.

We also offer a control board called the WattZilla C3 – Single Board EVSE. Customers use the board to design one EVSE that will pass European and American standards. It contains all the Command/Control/CCID20 functionality required by the NECA, IEC, UL and J1772 standards boards. This can help you to bring products to market faster, because you don’t have to do a bunch of the certification tests, saving time and tens of thousands of dollars. So people are happy to white-label it.

Our newest product is what we call the WattZilla Black Mamba. It’s a portable power cord that looks like a snake that ate a rat. On one end is the wall plug (offered as a NEMA 14-50 or 14-60 for 40 A or 48 A continuous rated output) and then a tube that has a lot of magic in it. The tube is custom-made with an inner polycarbonate layer surrounded by aluminum – it’s completely isolated from the outside case. You can drive over it with a truck – it’s designed to withstand a two thousand-pound test. Then there is a high-current 25 ft cable that goes to a J1772 coupler. As far as I can tell, we’re the only 48 A in this power cord form factor in the market.

Charged: So you’re targeting both plug-in vehicle owners and commercial customers like retail sites and parking garages?

Gangi: Yes. Most of our customers are a special kind of buyer that looks at the products and right away sees the intrinsic value. They understand that it’s a premium product that’s designed to a quality standard, and there are a fair amount of those customers. And then there are other people that need to be educated about why it’s the best value. So we explain that we designed these products because we were frustrated that we couldn’t find quality products made in America that were high-power and designed to last for a long time.

There is so much talk about DC fast charging, and we understand why it’s important for very high power. However, most of what is being installed is not very high power, but it is very expensive. We’ve heard of some people paying astronomical prices for DC fast chargers. In one instance it was about the price of 18 of our units. So instead of installing 18 80 A charging stations, they went with a single DC fast charger. What we’re preaching is more power in more places, and we think it’s clearly the future of the charging industry.

This article originally appeared in Charged Issue 26 – July/August 2016. – Subscribe now.